Hot spot-resistant photovoltaic dual-glass module

A double-glass module and photovoltaic technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of reduced hot spot effect of photovoltaic modules and inability to resist heat spots, so as to remove bad defects, solve technical difficulties, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

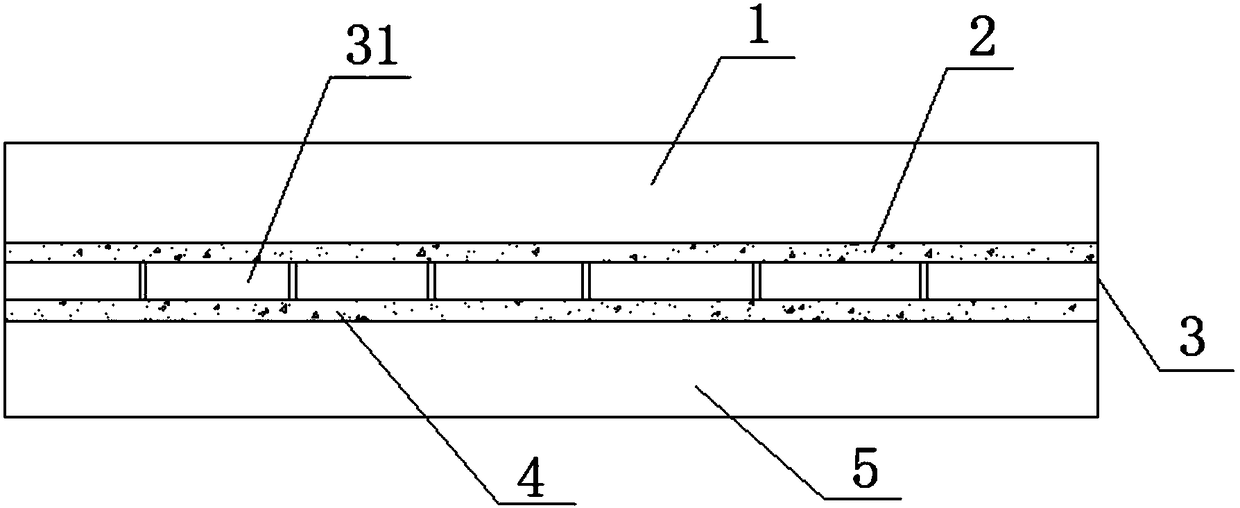

[0043] Such as figure 1 As shown, a heat-spot-resistant photovoltaic double-glass module includes front glass 1, upper packaging film 2 (commercially available material), battery sheet group 3, lower packaging film 4 (commercially available material) and back glass from top to bottom. 5. The battery slice group is composed of a plurality of battery slices 31 connected in series through interconnection strips 6, a diode 7 is arranged between adjacent battery slices, and both ends of the diode are respectively connected to adjacent battery slices.

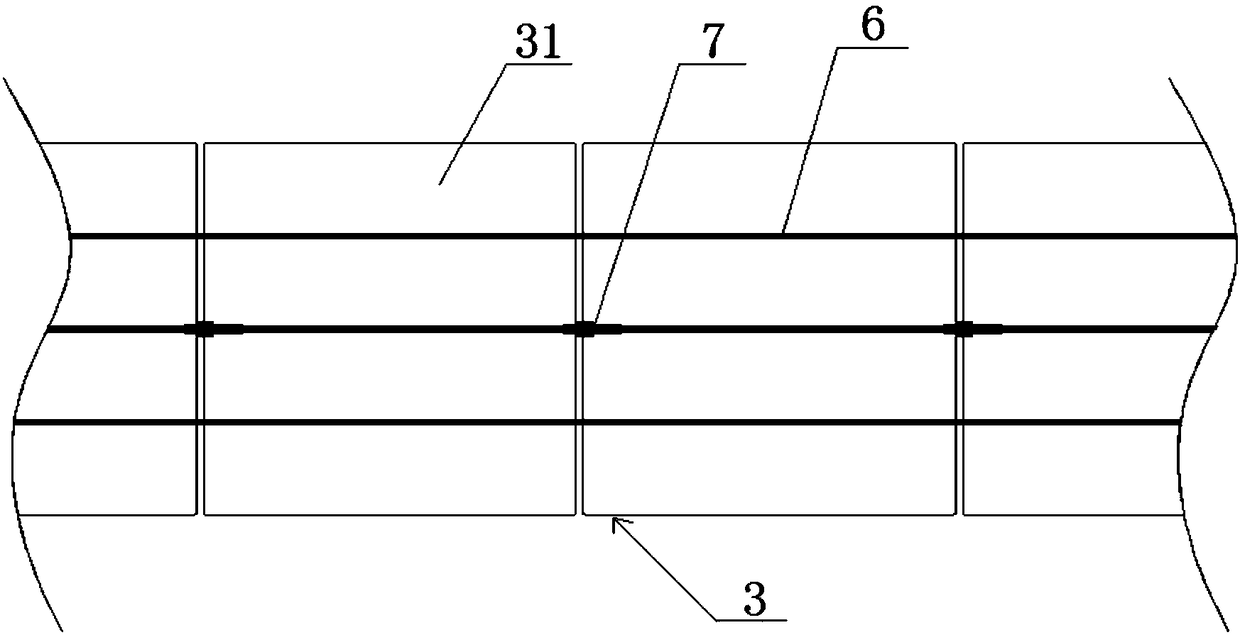

[0044] Such as figure 2 As shown, interconnection strips are evenly distributed on the front and back of the battery sheet group. There are three interconnection strips on each surface: upper, middle and lower. The middle interconnection strip coincides with the central axis of the battery sheet group, and the diodes are welded The interconnection bar in the middle of the back of the battery pack connects the connecting segments of...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is:

[0060] The cell group is composed of polycrystalline cells, and the process parameters of the lamination process are set as follows:

[0061] 1. The upper and lower chambers of the lamination chamber are vacuumed for 6 minutes, the vacuum degree is maintained at 0-20mbar, and the temperature is maintained at 140±2°C;

[0062] 2. One-stage heat preservation and pressurization: the time is 3 minutes, the upper chamber is pressurized to 100mbar, the lower chamber is vacuumed, the vacuum degree is maintained at 0-20mbar, and the temperature is maintained at 140±2°C;

[0063] 3. The second stage of heat preservation and pressurization: the time is 4 minutes, the upper chamber is pressurized to 200mbar, the lower chamber is evacuated, the vacuum degree is maintained at 0-20mbar, and the temperature is maintained at 140±2°C;

[0064] 4. Three-stage heat preservation and pressurization: the time is 4 minutes, the up...

Embodiment 3

[0071] Such as figure 1 As shown, a heat-spot-resistant photovoltaic double-glass module includes front glass 1, upper packaging film 2, battery sheet group 3, lower packaging film 4 and back glass 5 from top to bottom, and the battery sheet group consists of multiple The battery slices 31 are connected in series through interconnection bars 6 , two diodes 7 are arranged between adjacent battery slices, and the two ends of the diodes are respectively connected to adjacent battery slices.

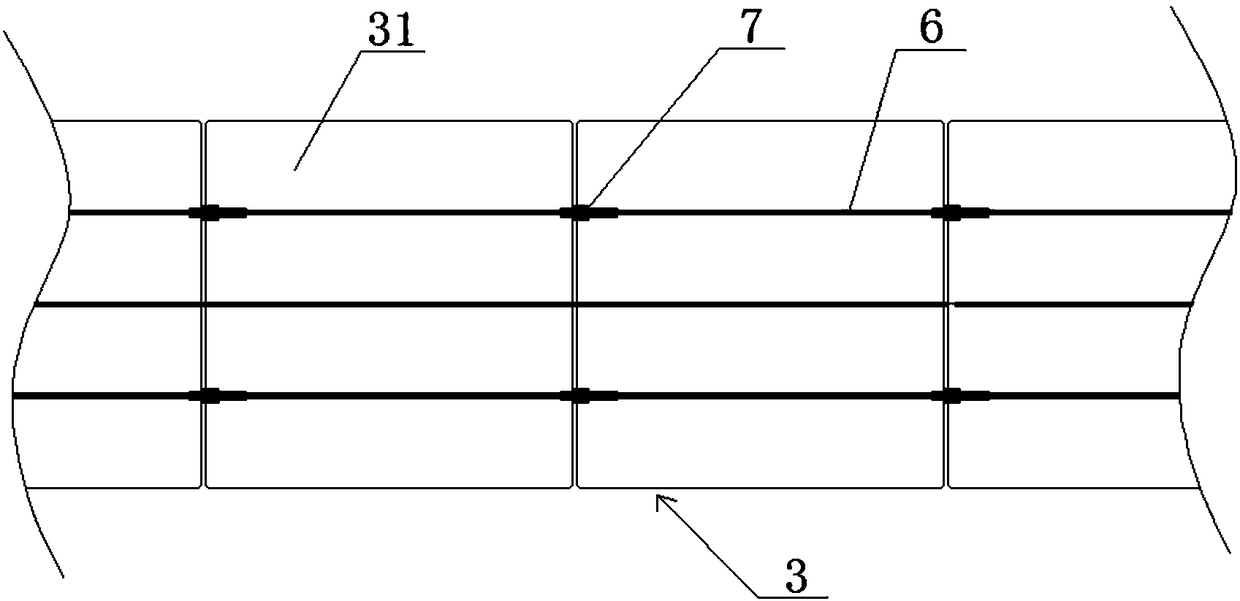

[0072] Such as image 3 As shown, interconnection strips are evenly distributed on the front and back of the battery sheet group. There are three interconnection strips on each surface: upper, middle and lower. The middle interconnection strip coincides with the central axis of the battery sheet group. A diode Welded on the connecting section where the upper interconnection bar on the back of the battery pack connects adjacent battery slices; another diode is welded on the connecting sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com