A half-slice photovoltaic module circuit and a half-slice photovoltaic module

A photovoltaic module and slicing technology, which is applied in the field of solar cells, can solve the problems of power and module conversion efficiency limitations, production process limitations, and difficulty in mass production, etc., to achieve the reduction of hot spot effect, convenient welding operation, and lower operating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

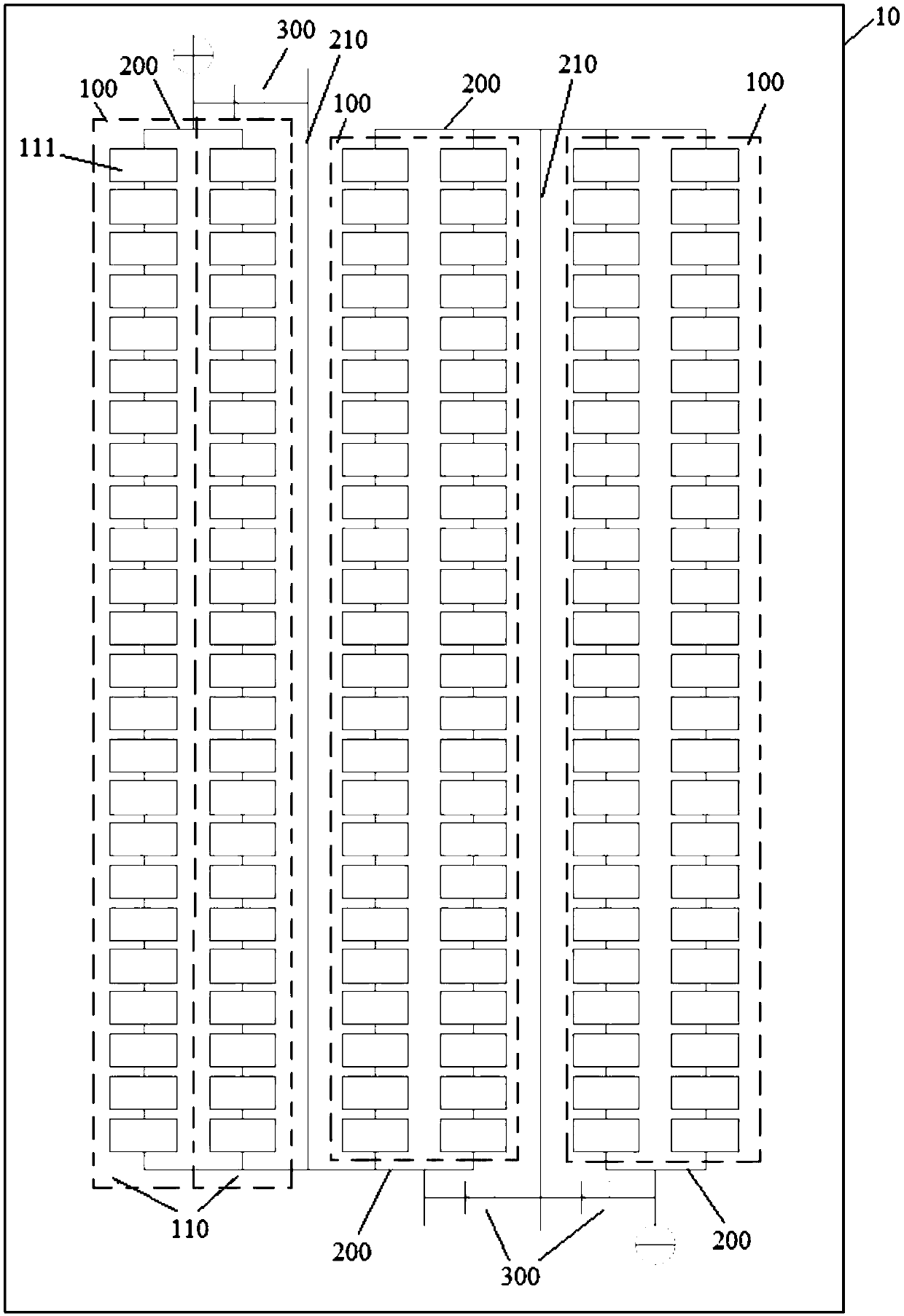

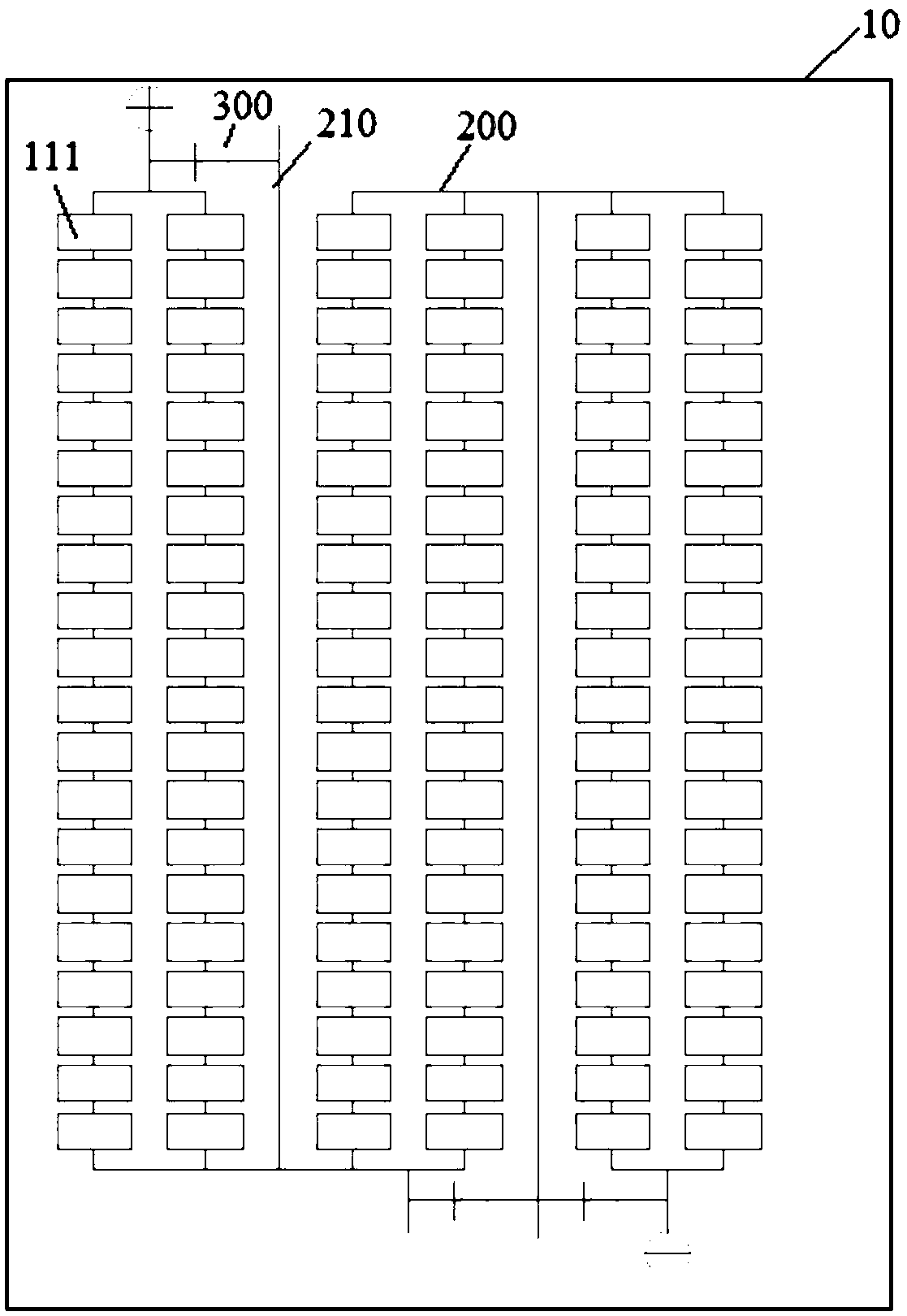

[0022] As a first aspect of the present invention, a half-slice photovoltaic module circuit is provided, wherein, such as figure 1 As shown, the half-slice photovoltaic module circuit 10 includes multiple groups of battery string units 100, each adjacent two groups of the battery string units 100 are connected in series through the first bus bar 200, and each group of the battery string units A diode 300 is connected in parallel at both ends via a second bus bar 210, each set of battery string units 100 includes two battery strings 110 connected in parallel, and each battery string 110 includes a plurality of batteries 111 connected in series, multiple sets The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com