Circuit board with symmetrical bonding pads

A symmetrical soldering and circuit board technology, applied to printed circuits, printed circuits, printed circuit components, etc., can solve problems such as virtual soldering, uneven lighting, and uneven distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described below with reference to the accompanying drawings and embodiments.

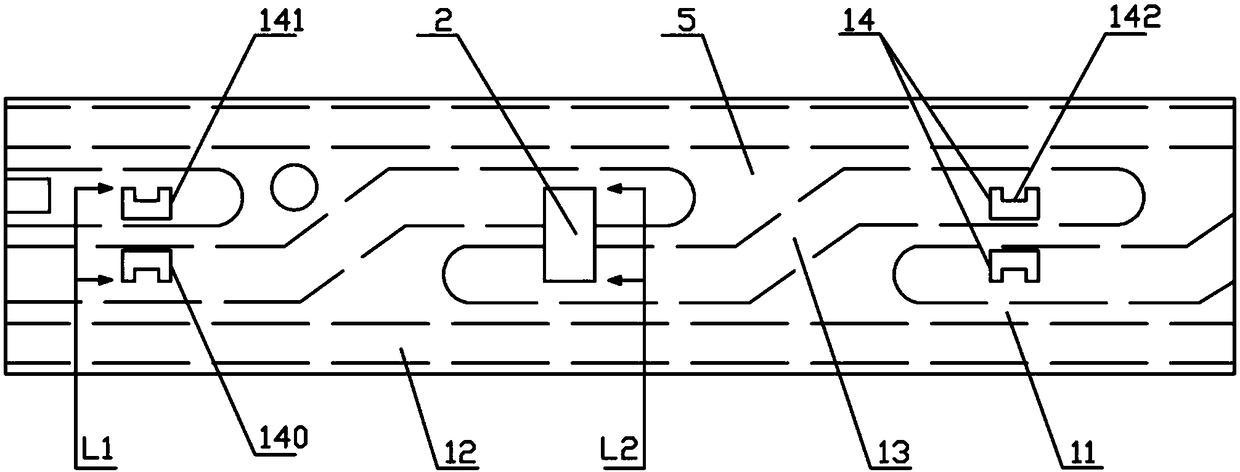

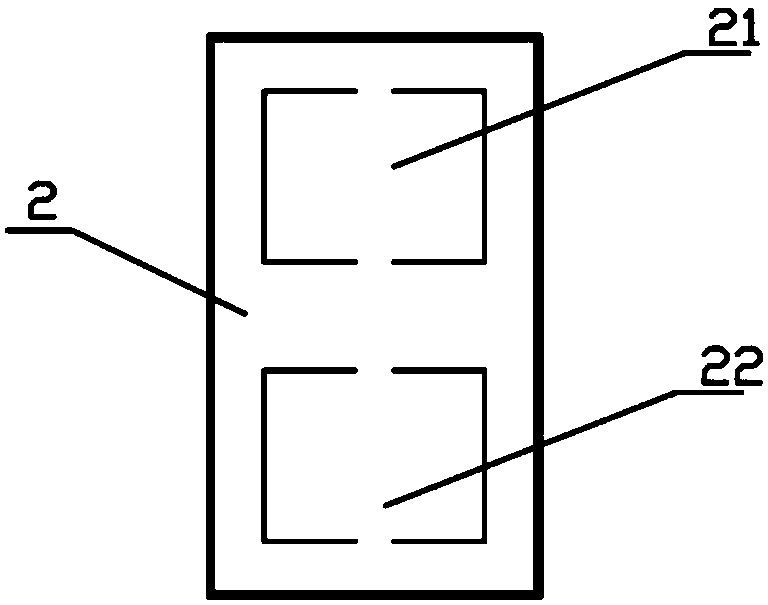

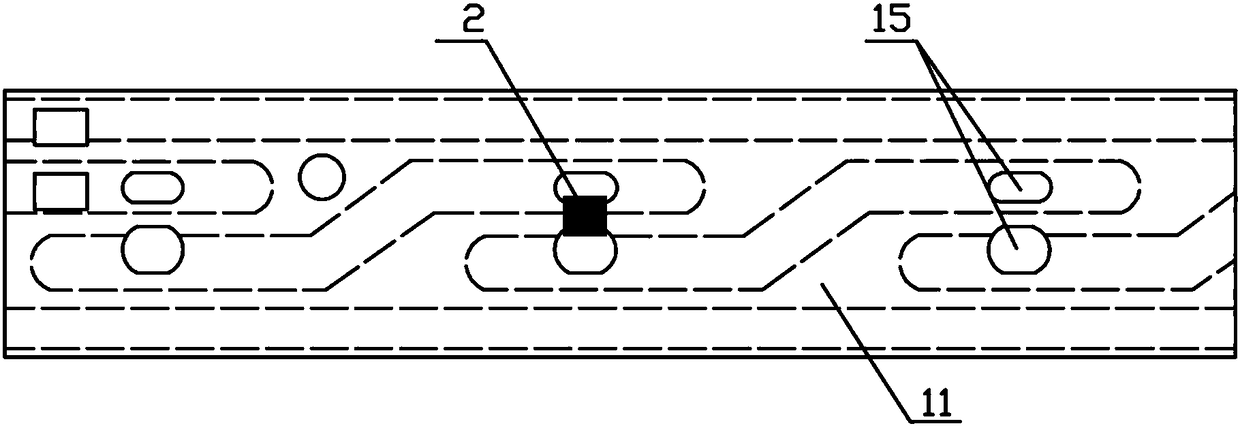

[0018] like figure 1 and figure 2 As shown, a circuit board with symmetrical pads according to the present invention includes a circuit board, and the circuit board 1 includes an insulating layer, a circuit layer 5 arranged on the insulating layer, and a solder resist covering the circuit layer 5 Layer 11, the position where the LED lamp 2 needs to be welded on the solder mask layer 11 is provided with an LED lamp bead pad 14, and the LED lamp bead pad 14 includes symmetrically arranged positive electrode pad 141 and negative electrode pad 140, positive electrode pad 141 and negative electrode The shape and size of the pads 140 are the same, and the outer contour L1 of the positive electrode pad 141 and the negative electrode pad 140 is smaller than or equal to the outer contour L2 of the LED lamp to be welded. With such a structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com