Paste-in-hole printing device

A technology of solder paste printing and solder paste, applied in printing, printing machines, printing processes, etc., can solve the problems of insufficient soldering space, inability to guarantee quality, waste of time, etc., achieve good soldering effect, solve long soldering time, and unique design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

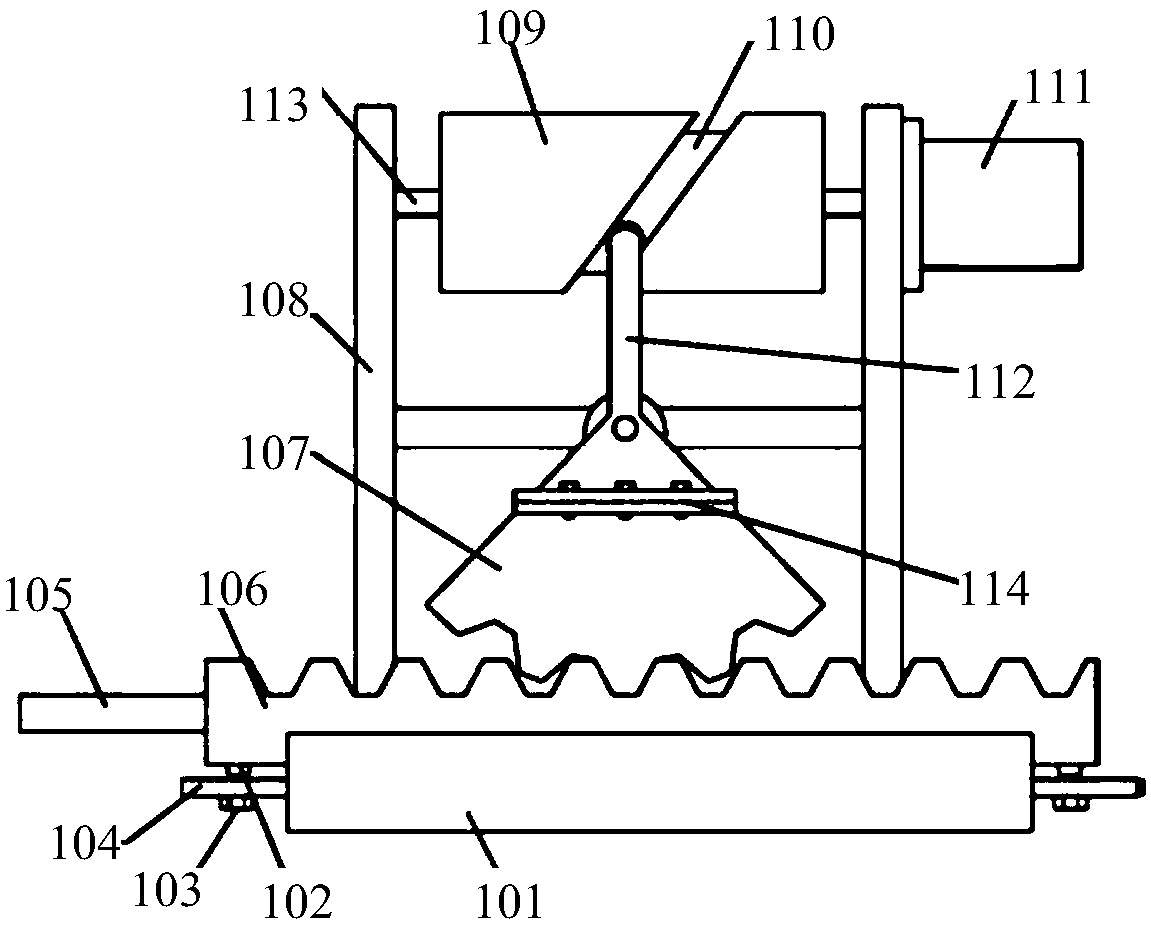

[0021] Such as figure 1 As shown, the through-hole solder paste printing device includes an X-Y axis motion platform 5 for carrying products and a stencil 3 matching the product, and through holes are opened on the stencil 3 corresponding to the parts on the product that need to fix components 7. The X-Y axis motion platform 5 is equipped with jigs for positioning and fixing the product 4 and the stencil 3. One side of the X-Y axis motion platform is arranged with a manipulator for picking and placing the product and the stencil, and a solder paste pushing unit is arranged above it 2. The solder paste pushing unit 2 includes a scraper seat and a bracket. The material of the bracket is aluminum alloy. The bracket includes two side bars and a beam installed on the top of the two side bars. A fixed horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com