Vibrating screen assembly and vibrating screen device

A technology of vibrating screen and components, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of high processing cost, unenvironmental protection, and high liquid content of drilling cuttings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

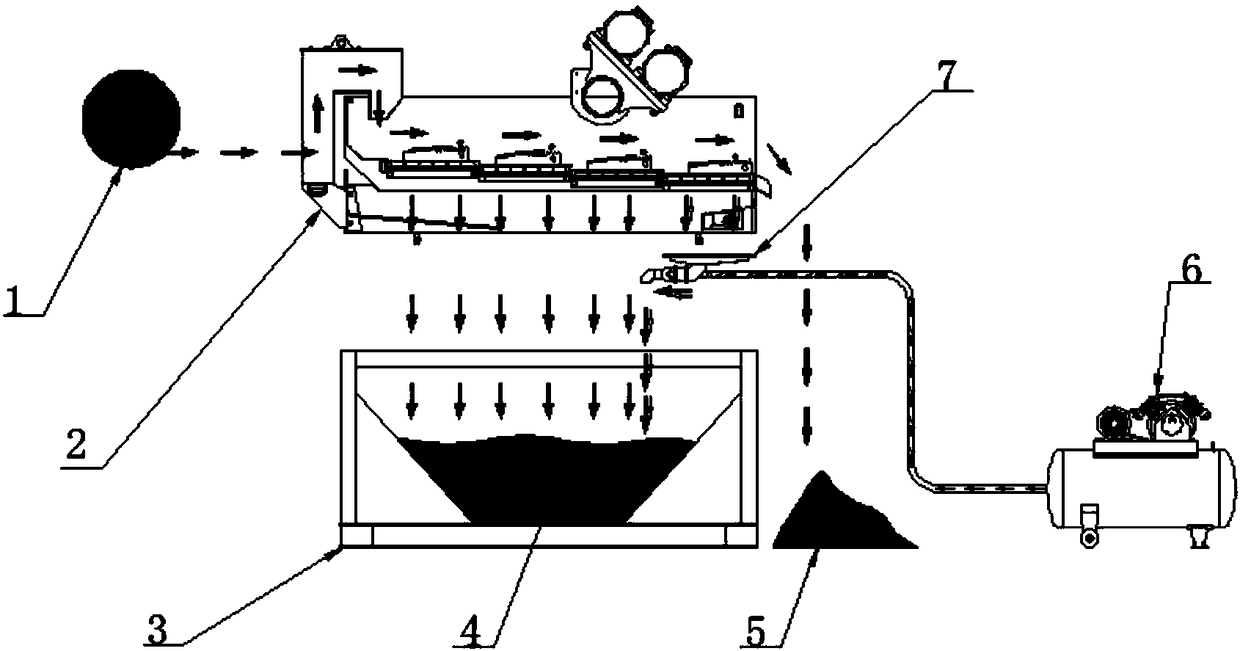

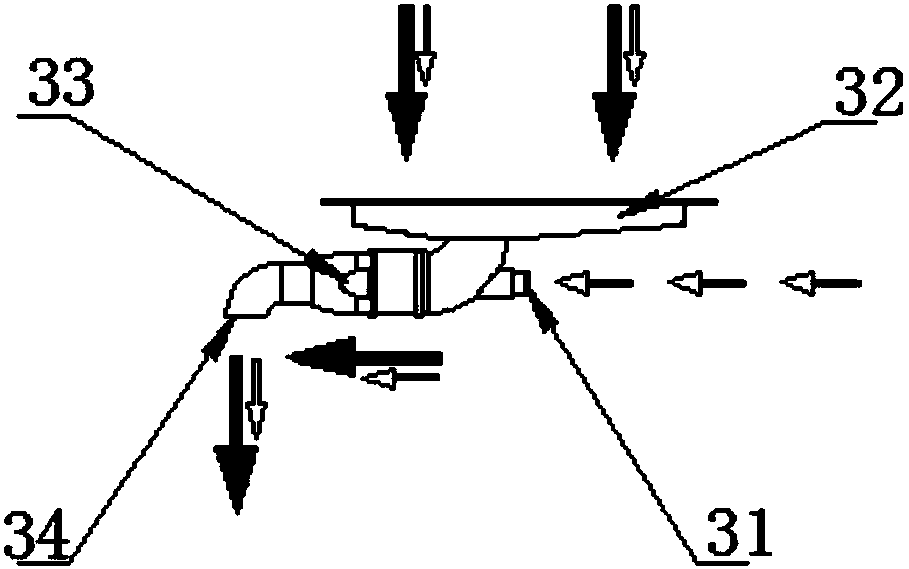

[0040] like Figure 1 to Figure 3 As shown, the vibrating screen assembly provided by the embodiment of the first aspect of the present invention includes: a vibrating screen 2 and a tank body 3, wherein a vacuum adsorption funnel arranged between the vibrating screen 2 and the tank body 3 is also included 7. Passing compressed air into the vacuum adsorption funnel 7 can generate negative pressure; the vibrating screen 2 includes a plurality of screens, and the vacuum adsorption funnel 7 is arranged corresponding to the screens.

[0041] The vibrating screen 2 assembly provided by the present invention also includes a vacuum adsorption funnel 7 arranged between the vibrating screen 2 and the tank body 3. Compressed air can be introduced into the vacuum adsorption funnel 7 to generate negative pressure. The adsorption funnel 7 can absorb the mud on the screen into the tank body 3, so that the liquid phase content in the cuttings 5 is reduced, the moisture content of the cutti...

Embodiment 2

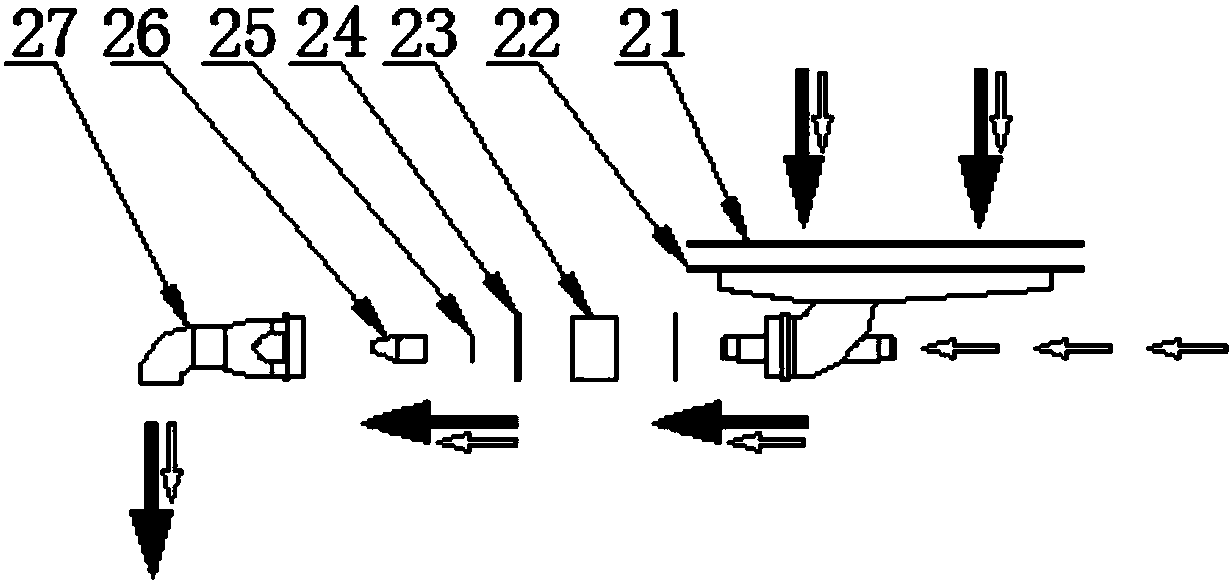

[0056] In any of the above technical solutions, further, a plurality of screens are evenly distributed along the feed port of the vibrating screen 2 to the discharge port, and the vacuum adsorption funnel 7 corresponds to the Screen settings. The funnel 22 of the vacuum adsorption funnel 7 can be arranged corresponding to the bottom of each screen.

[0057] Because the liquid phase content of the last sieve (at the outlet) is smaller than that of the previous sieve, it is not easy to separate. The best solution is to be provided with a vacuum adsorption funnel 7 at the bottom of the last sieve. The rest are the same as the first embodiment, and will not be repeated here.

[0058] The vibrating screen 2 assembly provided by the present invention has the following working steps: using the Venturi principle of the nozzle 26, the compressed air produced by the air compressor 6 enters the negative pressure generating chamber 33 of the vacuum adsorption funnel 7, and the generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com