Oil-containing sludge recycling process and device thereof

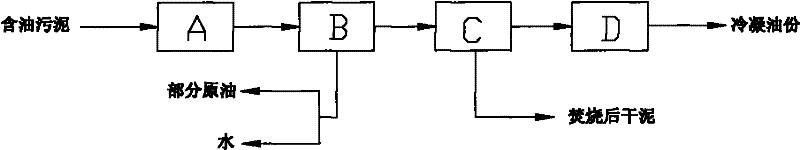

A treatment device and resource-based technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problem of sediment quality, high particle size requirements, difficulty in eliminating oily sludge, Sewage, waste residue discharge and other issues, to achieve the effect of low treatment cost, large-scale continuous industrial production, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

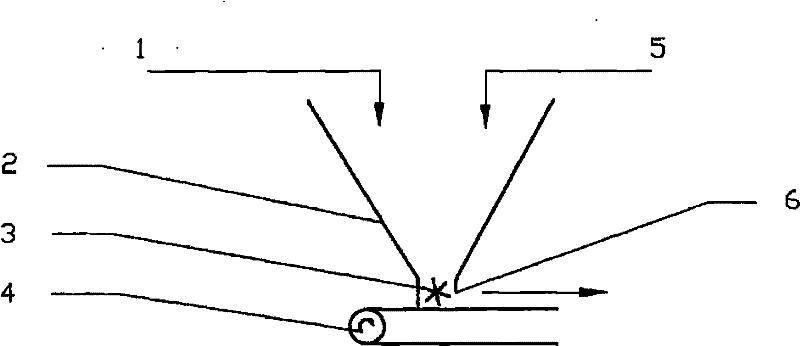

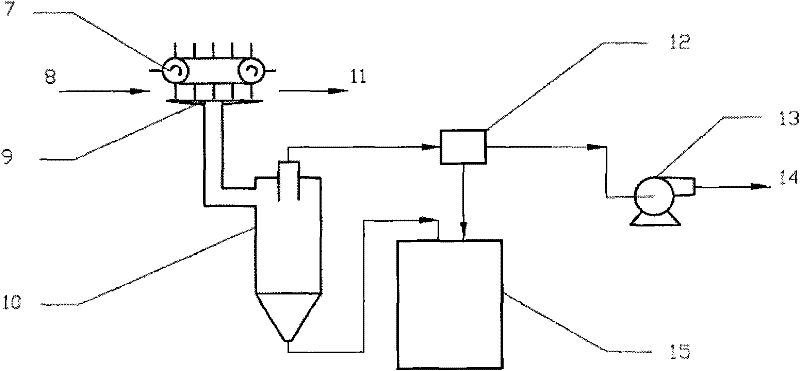

Method used

Image

Examples

Embodiment 1

[0045] The sedimentation tank bottom sludge provided by a certain department of Daqing Oilfield was used as raw material, and the oil content of the sample was relatively high (36.18% oil, 19.76% water). Samples were fed into the processing unit at 1 kg / min through a mixed feed. The effective pressure drop of the vacuum filtration is maintained at 0.63atm. Under this pressure drop, 71% of the liquid contained in the sludge can be filtered out, and the liquid content in the sediment is reduced to 28.44%. 1.83 improved to 7.70. After static stratification, the liquid obtained by suction filtration is stratified into oil phase 0.2060kg / min and water phase 0.1905kg / min. The sediment after vacuum filtration enters the distillation device, and the retention time for the sediment to pass through the upper layer is 10min. The average temperature of the distillation layer is 450°C, and the oily sludge is heated on the separator to evaporate the contained oil and water. After the dist...

Embodiment 2

[0049] In this embodiment, the oily sludge produced during the mining and production process provided by a certain department of Daqing Oilfield is used as raw material, and the water content of the sample is relatively high (oil 13.28%, water 43.72%). Samples were also fed into the processing unit at 1 kg / min via mixed feed. The effective pressure drop of the vacuum filtration is maintained at 0.48atm. Under this pressure drop, 68.90% of the liquid contained in the sludge can be filtered out, and the liquid content in the sediment is reduced to 30.58%. The oil-water ratio in the filtered sediment is as follows: 0.30 improved to 1.28. After standing and stratifying, the suction filtered liquid is separated into oil phase at 0.0210kg / min and water phase at 0.3720kg / min. The filtered sediment enters the distillation device, the retention time for the sediment to pass through the upper layer is 15 minutes, and the average temperature of the distillation layer is 400°C. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com