Cooling base used for 3D printer

A technology of 3D printers and cooling channels, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as large cooling range, burn users, and different cooling degrees of raw materials, so as to save work interval time and improve work efficiency. Efficiency, fast warm-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

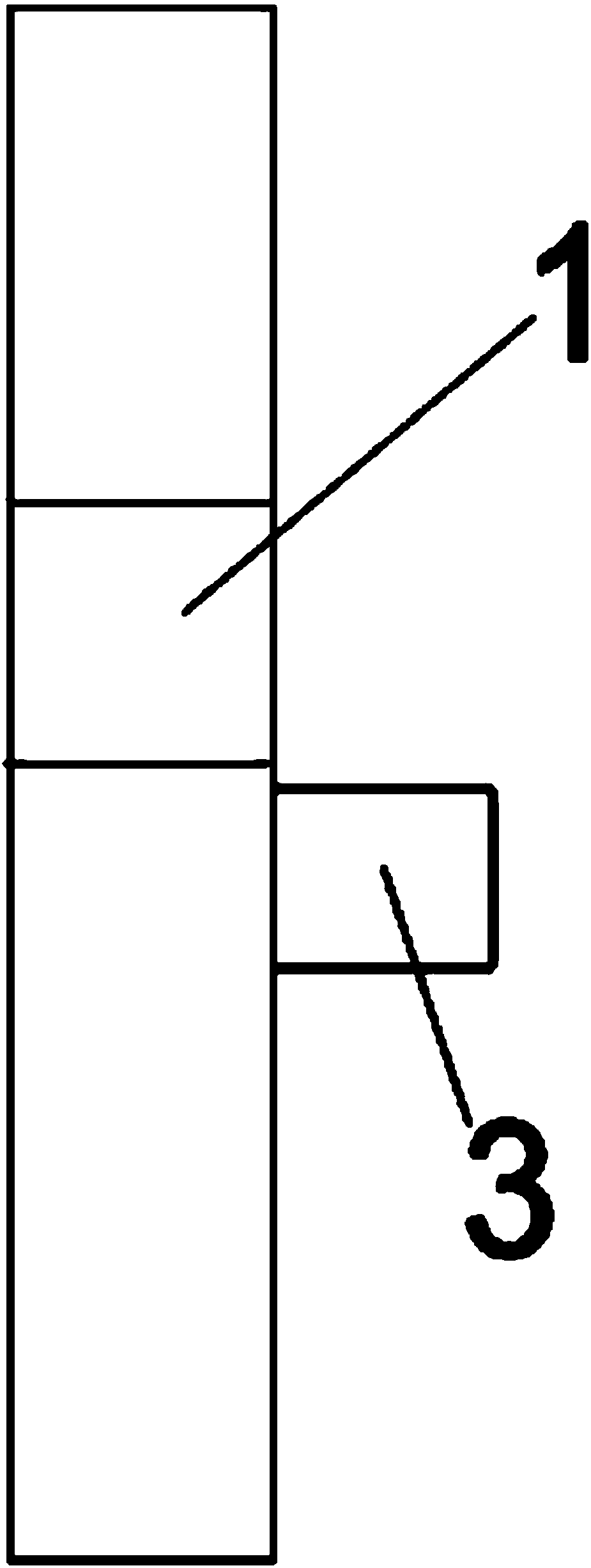

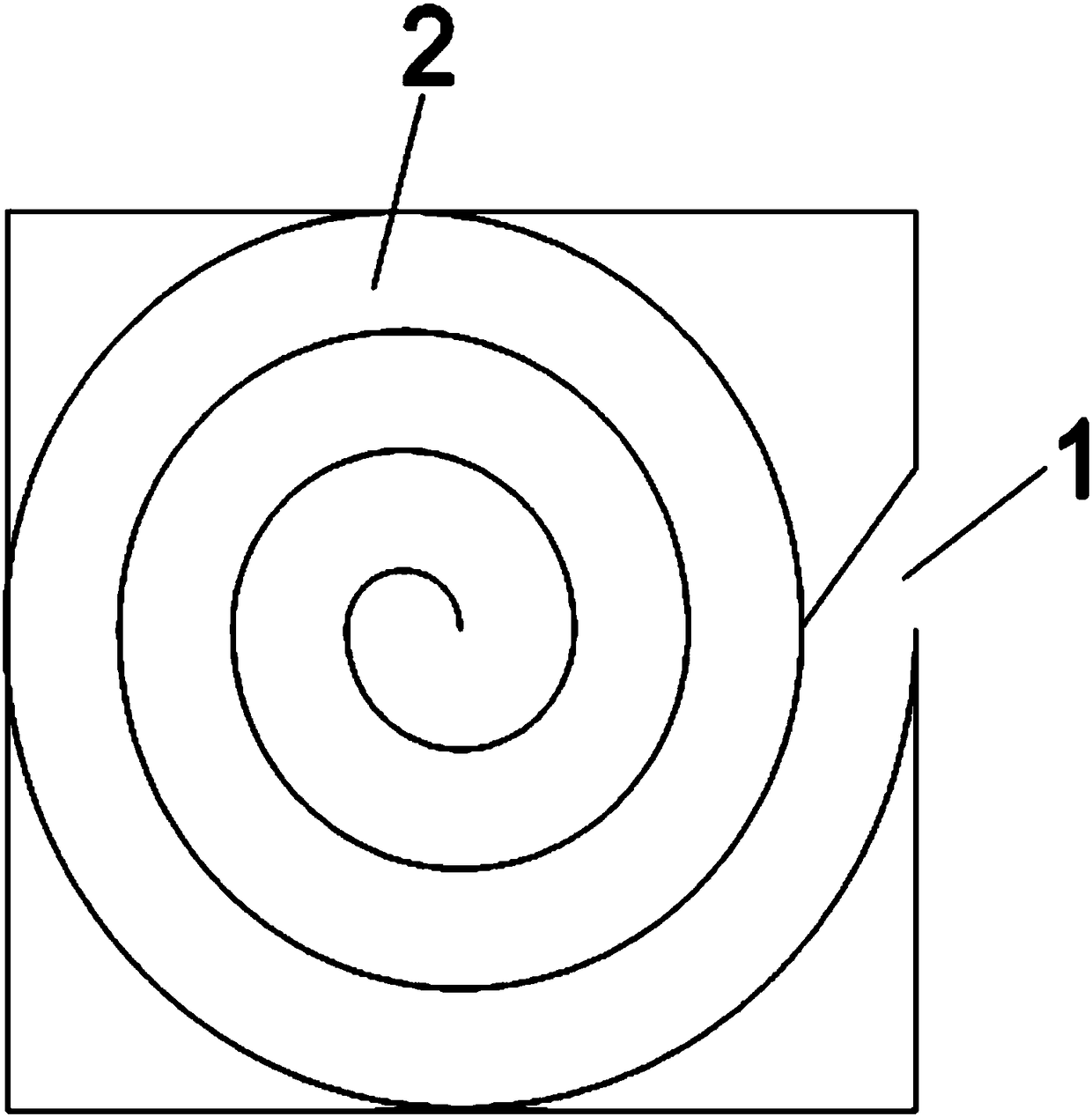

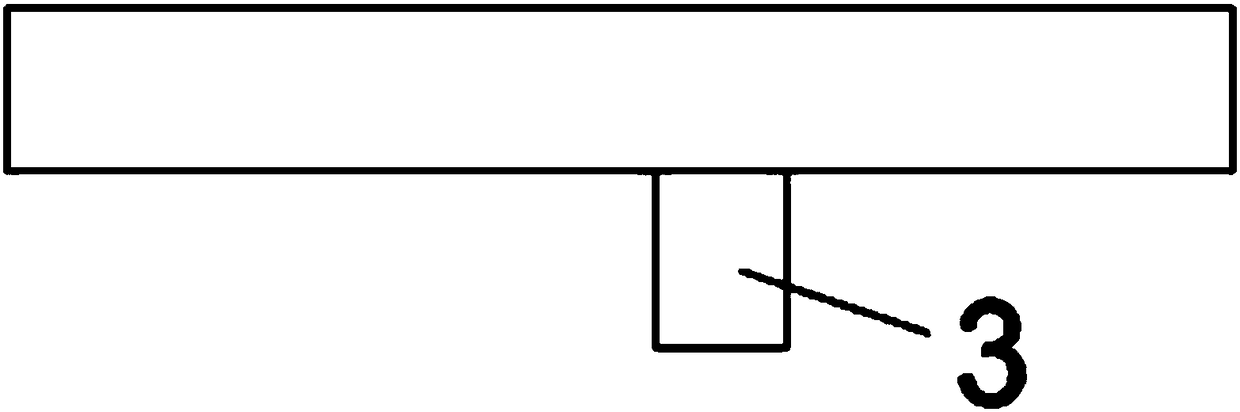

[0016] like figure 1 As shown, a cooling base for a 3D printer includes a base body, the base body includes an inlet 1, a cooling channel 2 and an outlet 3; the inlet 1 is arranged on the side of the base body; the outlet 3 is arranged on the side of the base body Bottom surface; the interior of the main body of the base is provided with a cooling channel 2, and the inlet 1 and the outlet 3 are communicated through the cooling channel 2.

[0017] The cooling channel 2 is spiral, and the outer circular edge of the cooling channel 2 is tangent to the main body of the base.

[0018] The outlet 3 is arranged in the middle of the spiral shape of the cooling channel 2 .

[0019] Inlet 1 is connected to the cooling medium input pump; outlet 3 is connected to the cooling medium output pump.

[0020] The cooling medium is water.

[0021] The water enters the spiral cooling channel 2 through the inlet 1 and is pumped into the spiral cooling channel 2 through the entire base body, and...

Embodiment 2

[0026] During the whole cooling process, the inlet 1 is connected to the cooling medium input pump; the outlet 3 is connected to the cooling medium output pump. When the cooling work is completed and the printing work is to continue, the working base needs to be preheated again. The cooling medium input pump and the cooling medium output are reversed at the same time, and the hot water removed during cooling is re-inputted into the base to quickly preheat the base, saving heating time and improving printing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com