Bamboo filament collection device for bamboo splint filament drawing machine

A technology of collecting device and wire drawing machine, which is applied in the direction of packaging, transportation and packaging, and binding machine parts, etc., can solve the problems of increasing labor cost and high labor intensity of wire drawing, so as to improve applicability and work stability, and improve work efficiency. Stability, effect of reducing difficulty in sorting and bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

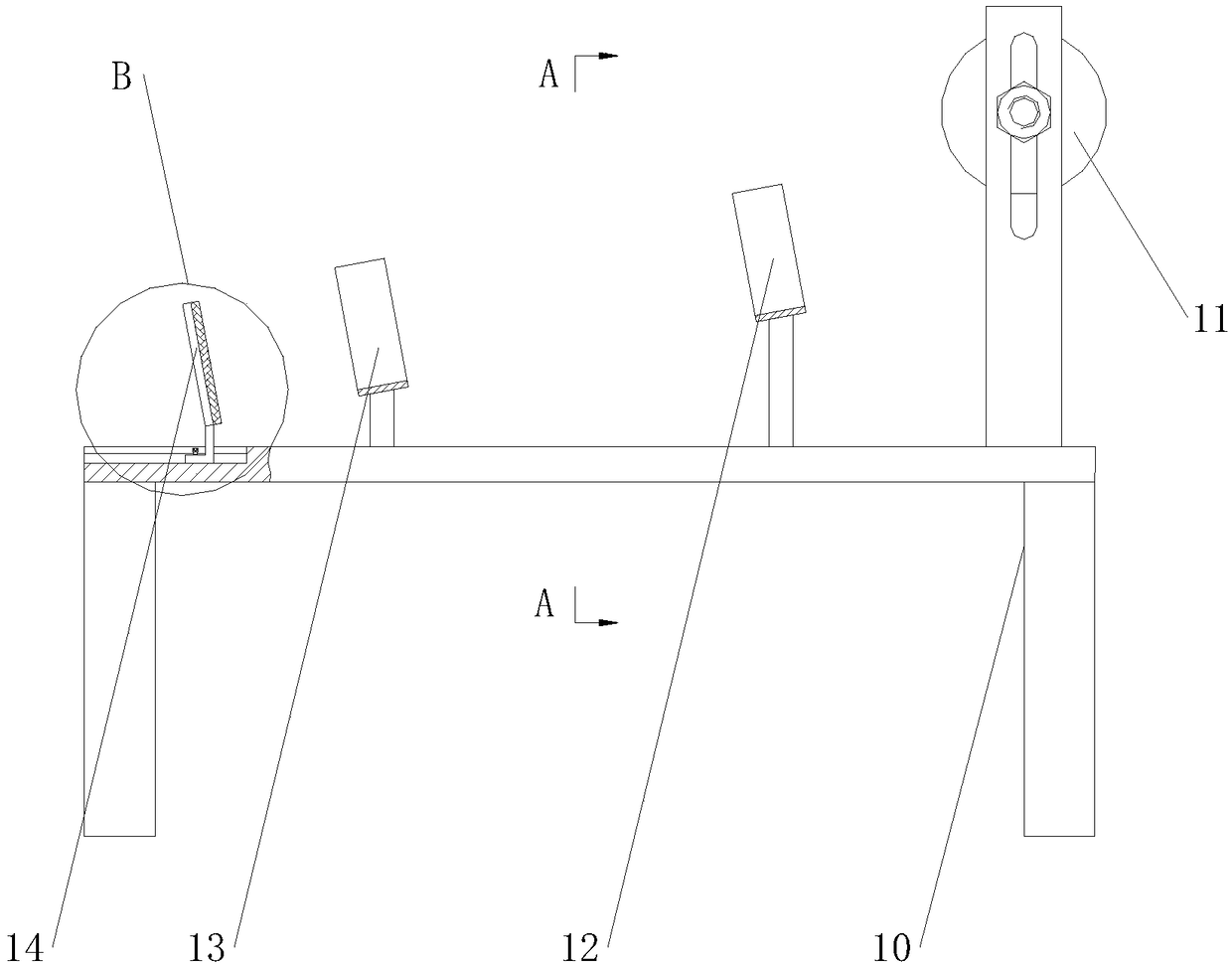

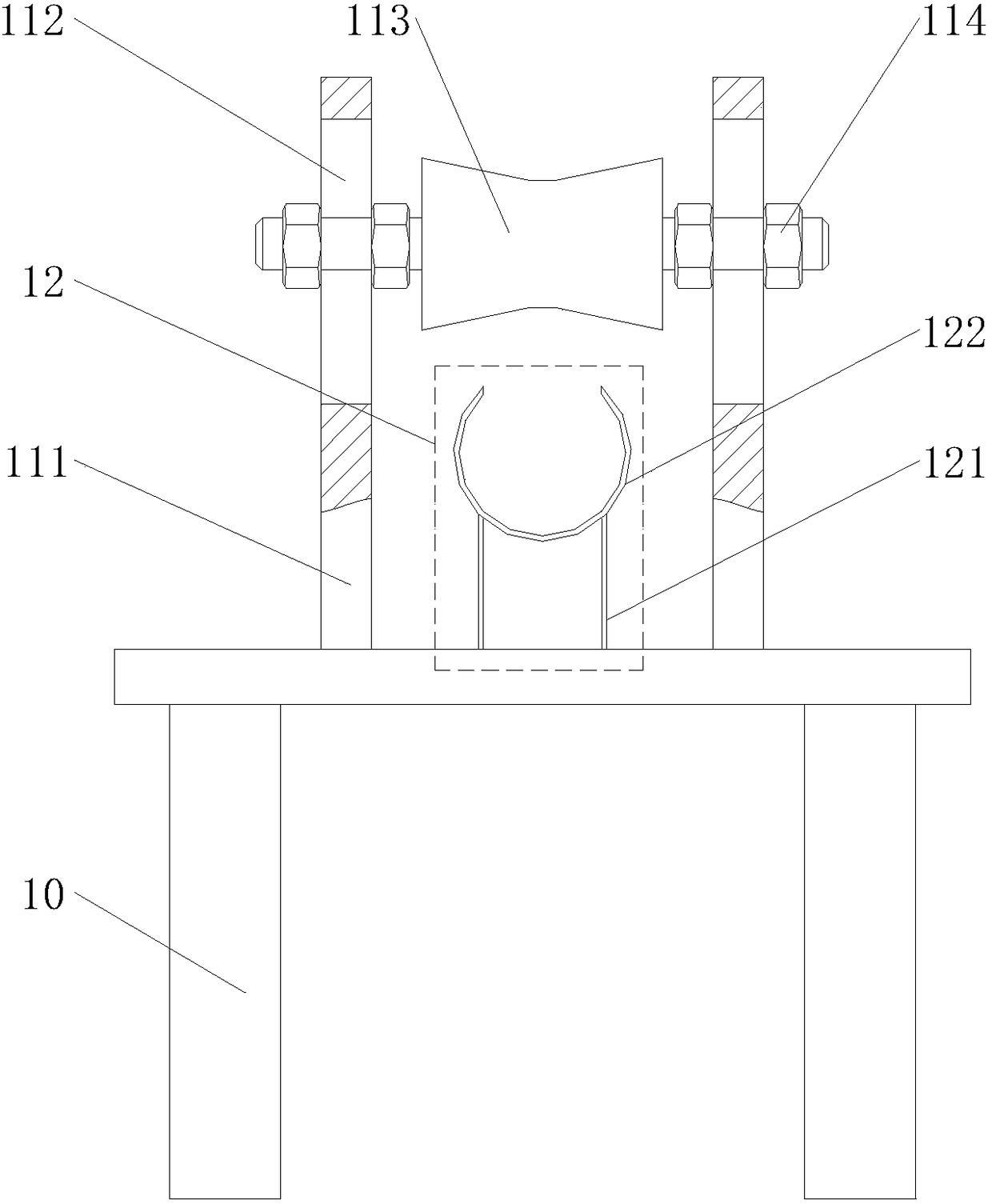

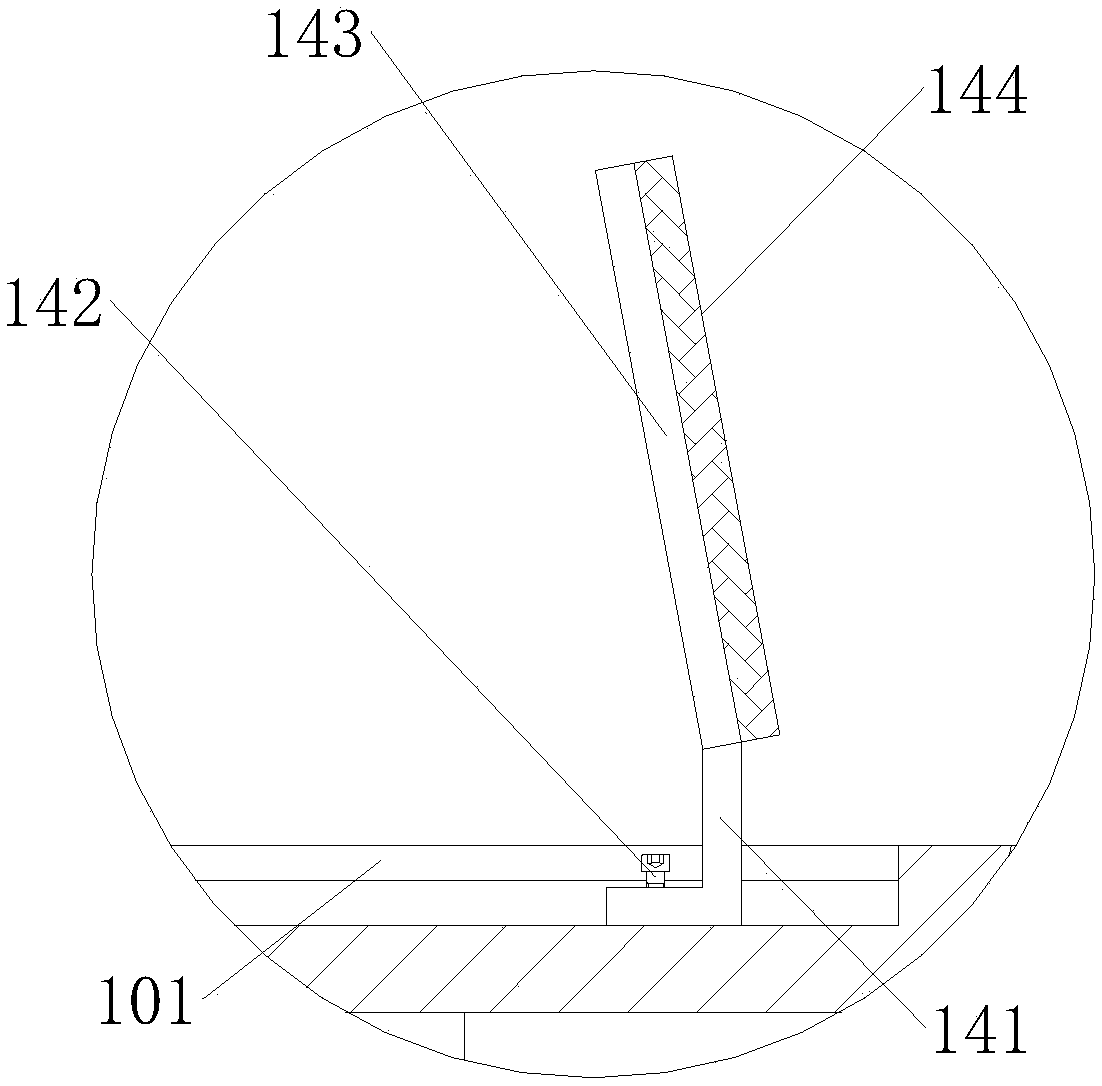

[0012] Example. Bamboo thread collecting device for bamboo strip drawing machine, constituted as figure 1 As shown, the base 10 is included, and the upper end of the base 10 is provided with a V-shaped wheel set 11, a first bracket 12, a second bracket 13 and a stopper 14 in turn, and the V-shaped wheel set 11 includes a mounting frame 111, and the mounting frame 111 The top is provided with a V-shaped wheel 113 through the long hole 112, and the two sides of the mounting frame 111 are provided with fixing nuts 114 that cooperate with the V-shaped wheel 113. 141, one side of the guide seat 141 is threadedly connected with a set screw 142, the upper end of the guide seat 141 is provided with an inclined baffle plate 143, and the side of the baffle plate 143 near the second bracket 13 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com