Intelligent multifunctional stacked screw type sludge dewatering machine

A technology of sludge dewatering machine and stacking screw, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc. It can solve the problems of low intelligence, inconvenient cleaning, and single function. Achieve the effect of improving the degree of intelligence, improving efficiency and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

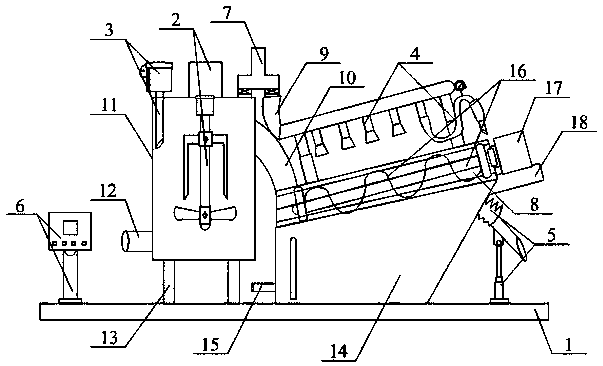

[0045] as attached figure 1 to attach Figure 7 shown

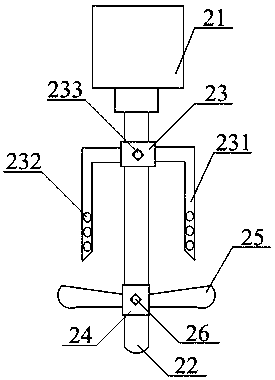

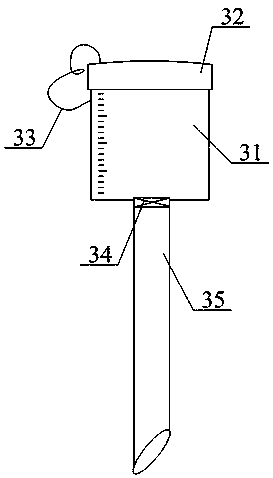

[0046] The present invention provides an intelligent multifunctional screw-stacking sludge dewatering machine, which includes a shock-absorbing base 1, a stirring and crushing shaft structure 2, a dosing hopper structure 3, an adjustable spray pipe structure 4, a hopper structure 5, and a control Cabinet structure 6, tap water connection tee pipe 7, concentration box 8, telescopic pipe 9, feed pipe 10, flocculation box 11, bath pipe 12, support frame 13, filtrate recovery tank 14, drain pipe 15, stacked screw spindle 16. The dehydration motor 17 and the support plate 18, the stirring and crushing shaft structure 2 is bolted to the upper middle position of the flocculation box 11; the dosing hopper structure 3 runs through the left side of the upper surface of the flocculation box 11; The adjustable spray pipe structure 4 is bolted to the upper surface of the concentration box 8; the hopper structure 5 is bolted to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com