Water discharge kerb and road

A technology of curb and body, applied in the field of drainage curb and roads including the drainage curb, can solve the problems of affecting drainage efficiency, difficult collection and cleaning of dirt, and many impurities, so as to ensure smooth drainage and improve drainage. Efficiency, the effect of reducing the frequency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

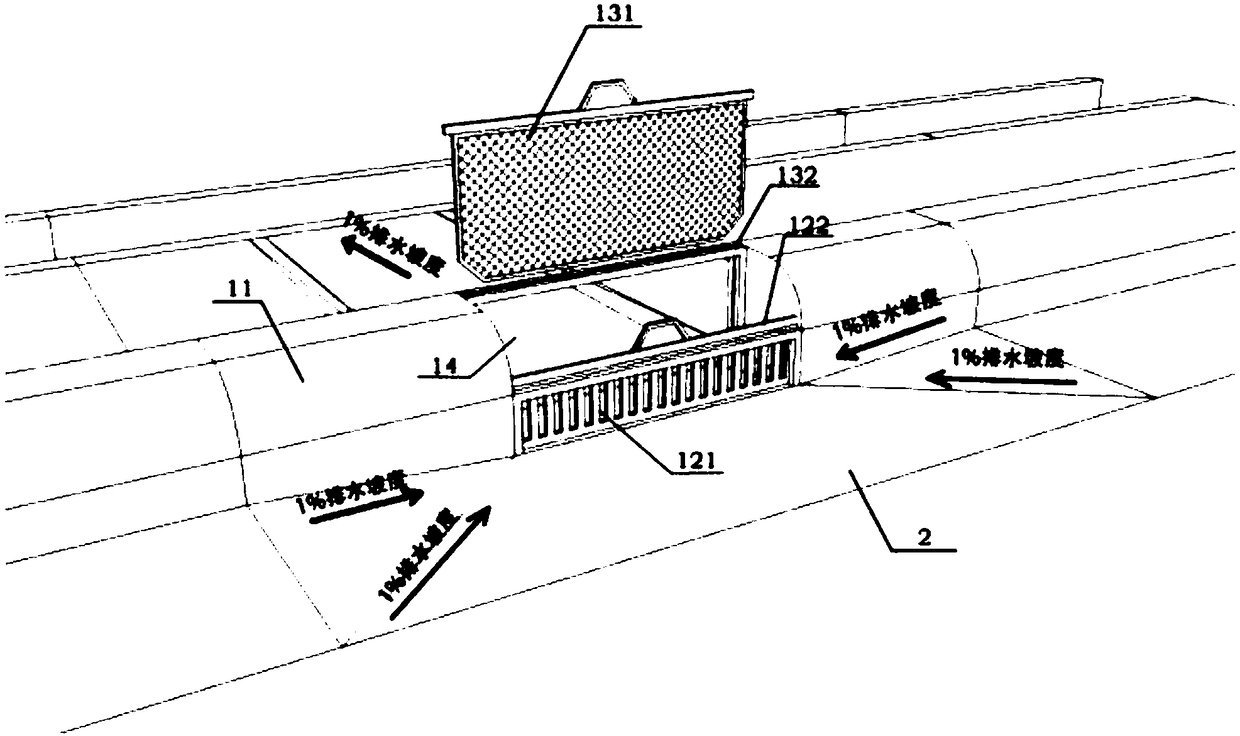

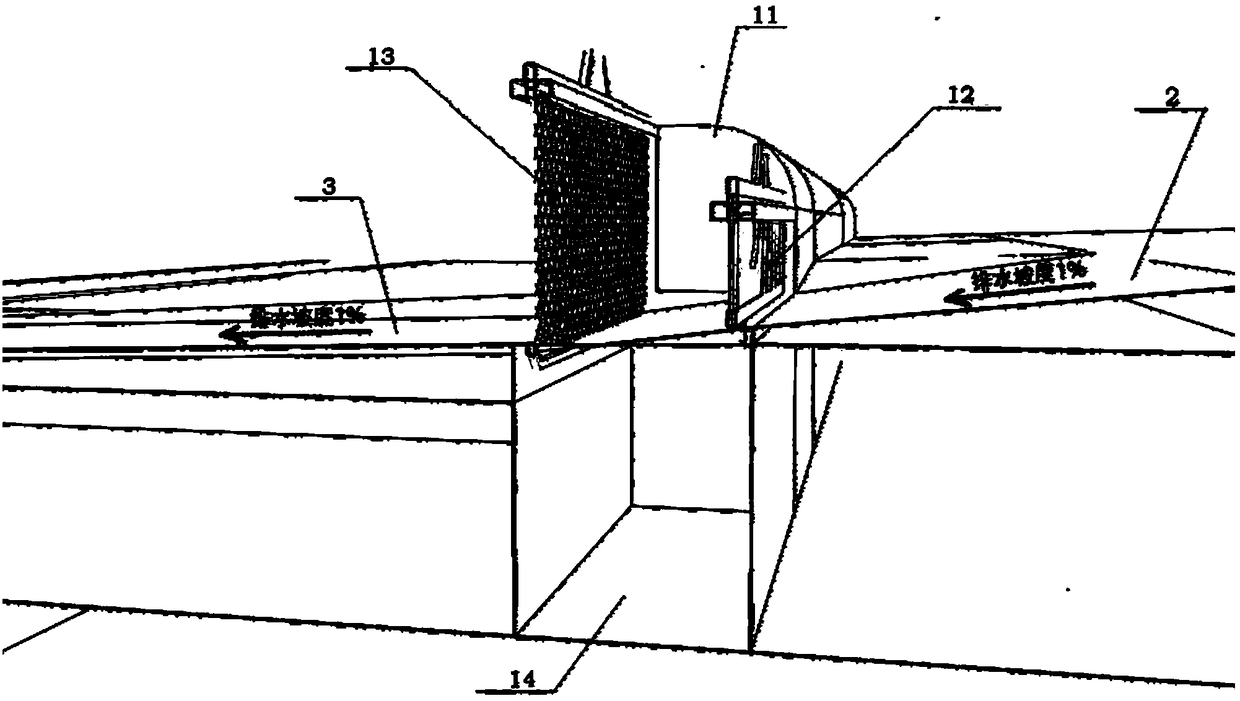

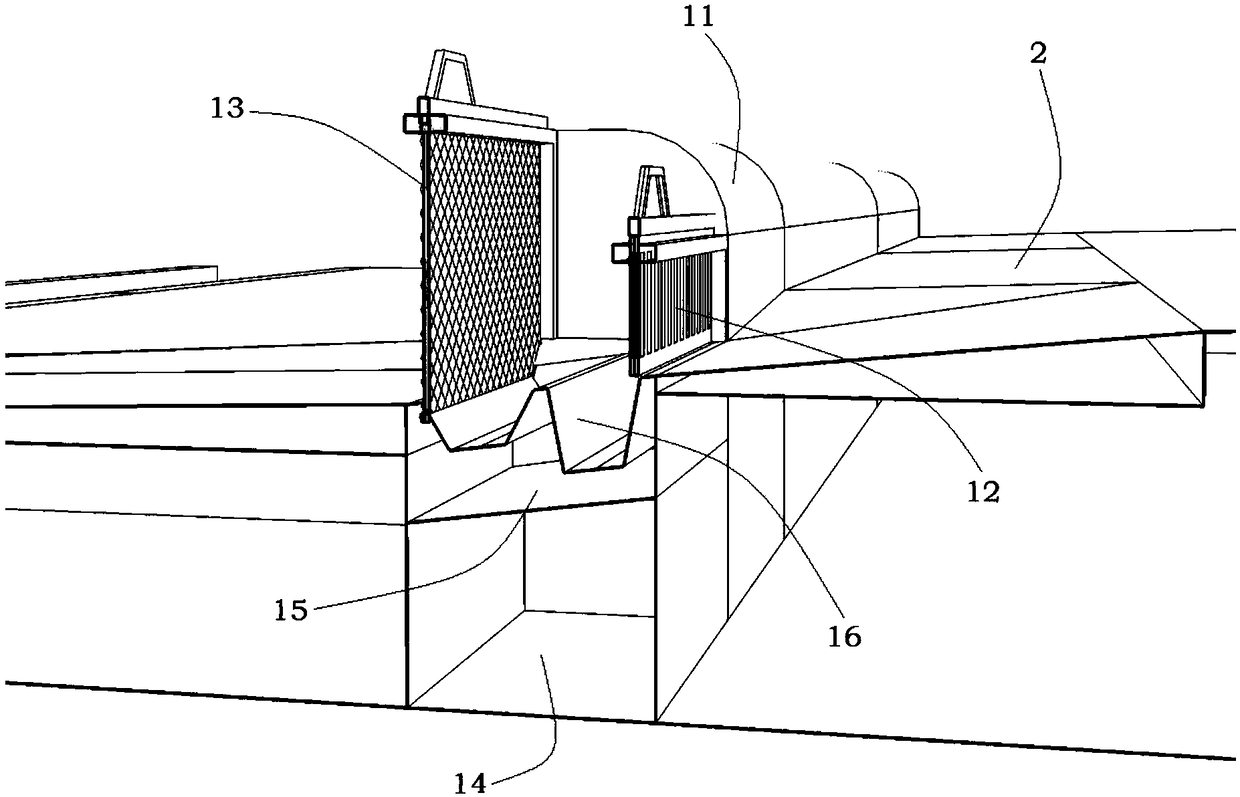

[0022] Such as figure 1 and figure 2 , the embodiment of the present invention provides a drainage curb, including a curb body 11, the curb body 11 is formed with a wall extending from the side wall of the road surface to the other side (ie, the side away from the road surface 2) The drainage channel is provided with a coarse filter unit 12 and a fine filter unit 13 in sequence along the drainage direction, and an overflow buffer channel 14 is formed between the coarse filter unit 12 and the fine filter unit 13 . Wherein, preferably, the above-mentioned coarse filter unit 12 is installed on the side wall of the road surface of the curb body 11, and the fine filter unit 13 is installed on the other side wall of the curb body 11, between the two There is a relatively long overflow buffer channel 14, which is convenient for the sedimentation and collection of dirt, and the filtrate filtered by the fine filter unit 13 is temporarily stored in the overflow buffer channel 14, whic...

Embodiment 2

[0034] Such as Figure 1-Figure 3 , the embodiment of the present invention relates to a road, including a roadbed 2, at least one side of the roadbed 2 is provided with a divider, and the divider includes a plurality of curbstones connected in series along the length direction of the road surface, at least one of which is the roadbed The curbstone is the drainage curbstone provided in the first embodiment above, and the specific structure of the drainage curbstone will not be repeated this time.

[0035] Preferably, as Figure 1-Figure 3 The road surface 2 near the drainage curb has a certain slope, preferably no less than 1%, in order to divert the accumulated water on the road surface 2 to the drainage curb. Preferably, drainage slopes are provided along the length direction of the road surface and the width direction of the road surface, so as to form a low-lying area converging toward the coarse filter unit 12 .

[0036] Further, a section of drainage ramp 3 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com