Automobile gear-engaging sliding fuel saving device

A technology of belt and fuel saving in automobiles, applied in the field of auto parts, can solve problems such as easily damaged gearboxes, loss of engine braking effect, incomplete fuel combustion, etc., to prolong the sliding process with gears, reduce braking effects, and save fuel effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

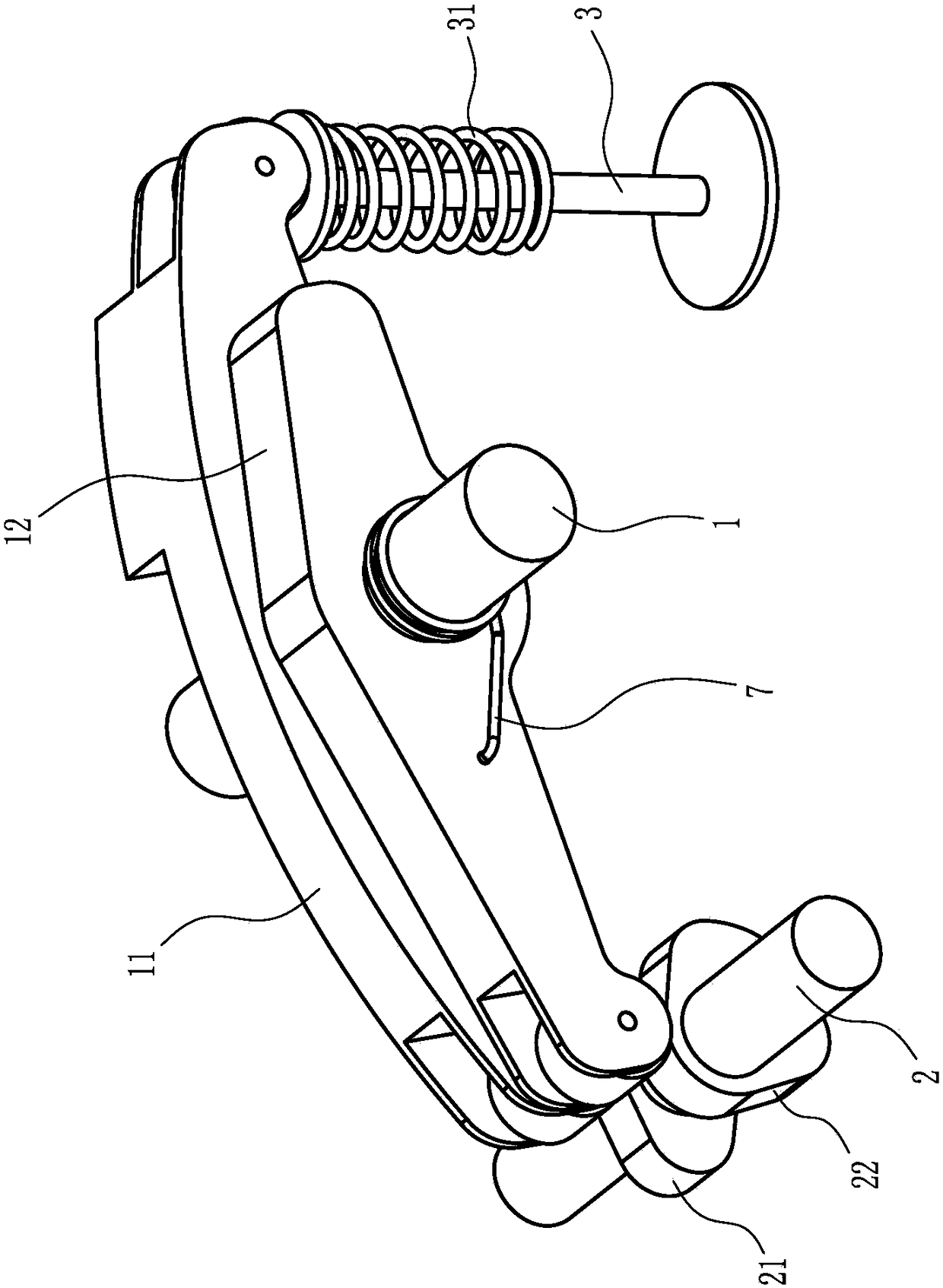

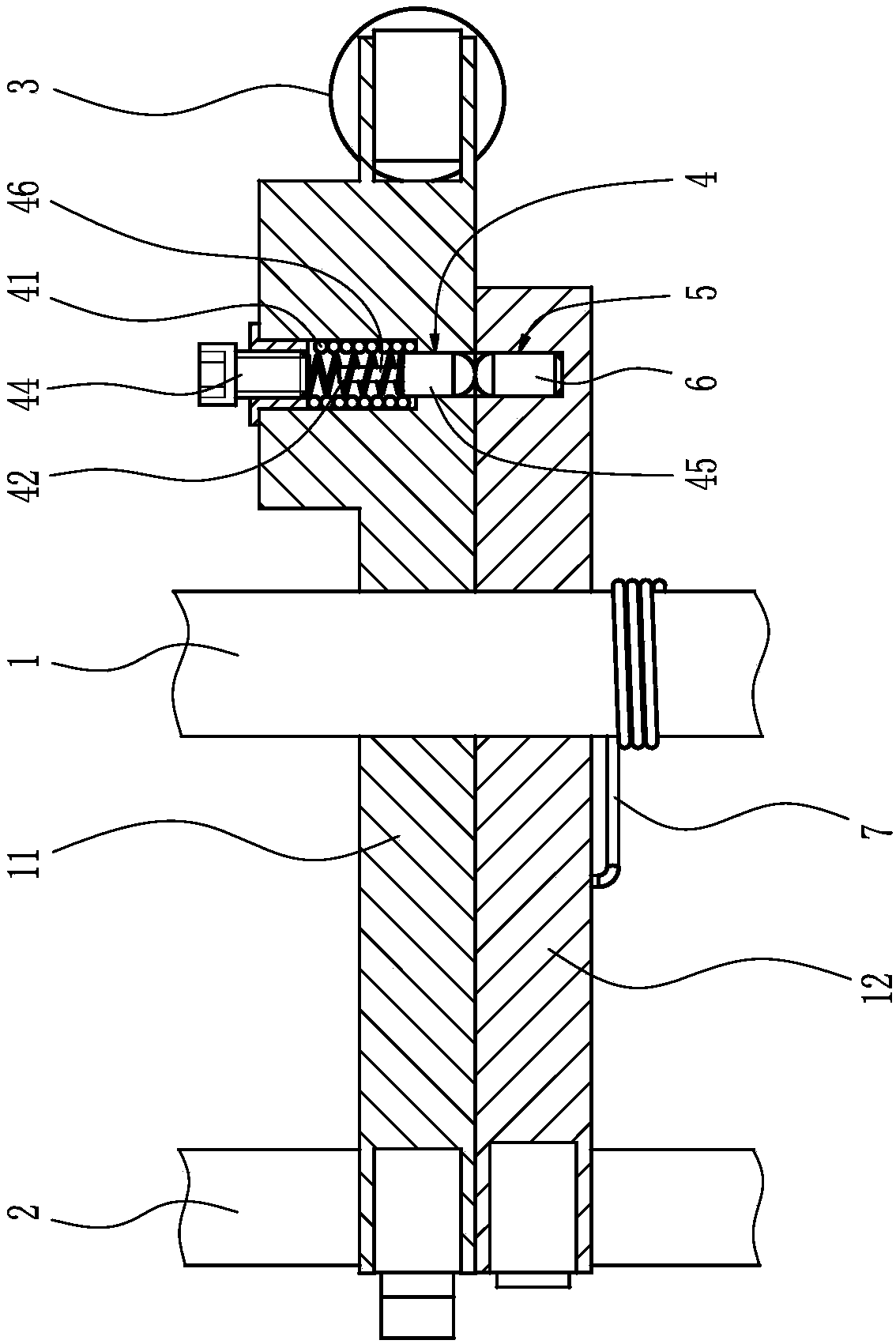

[0024] Embodiment one: if figure 1 and figure 2 As shown, the automobile sliding fuel-saving device with gears includes a rocker shaft 1 and a camshaft 2 installed on the engine. One end of the main rocker arm 11 corresponds to the main cam 21, and the other end of the main rocker arm 11 abuts against the intake valve 3 or the exhaust valve. The above-mentioned structure is a conventional structure of an existing engine. Of course, the intake valve A valve return spring 31 is also provided on the door 3 or the exhaust valve.

[0025] To facilitate the description of the principle of this embodiment, the following description takes the intake valve 3 as an example.

[0026] The four strokes of a four-stroke engine are respectively an intake stroke, a compression stroke, a power stroke, and an exhaust stroke, wherein the intake valve 3 is opened during the intake stroke, and the opening of the intake valve 3 is caused by the valve on the camshaft 2. The main cam 21 pushes on...

Embodiment 2

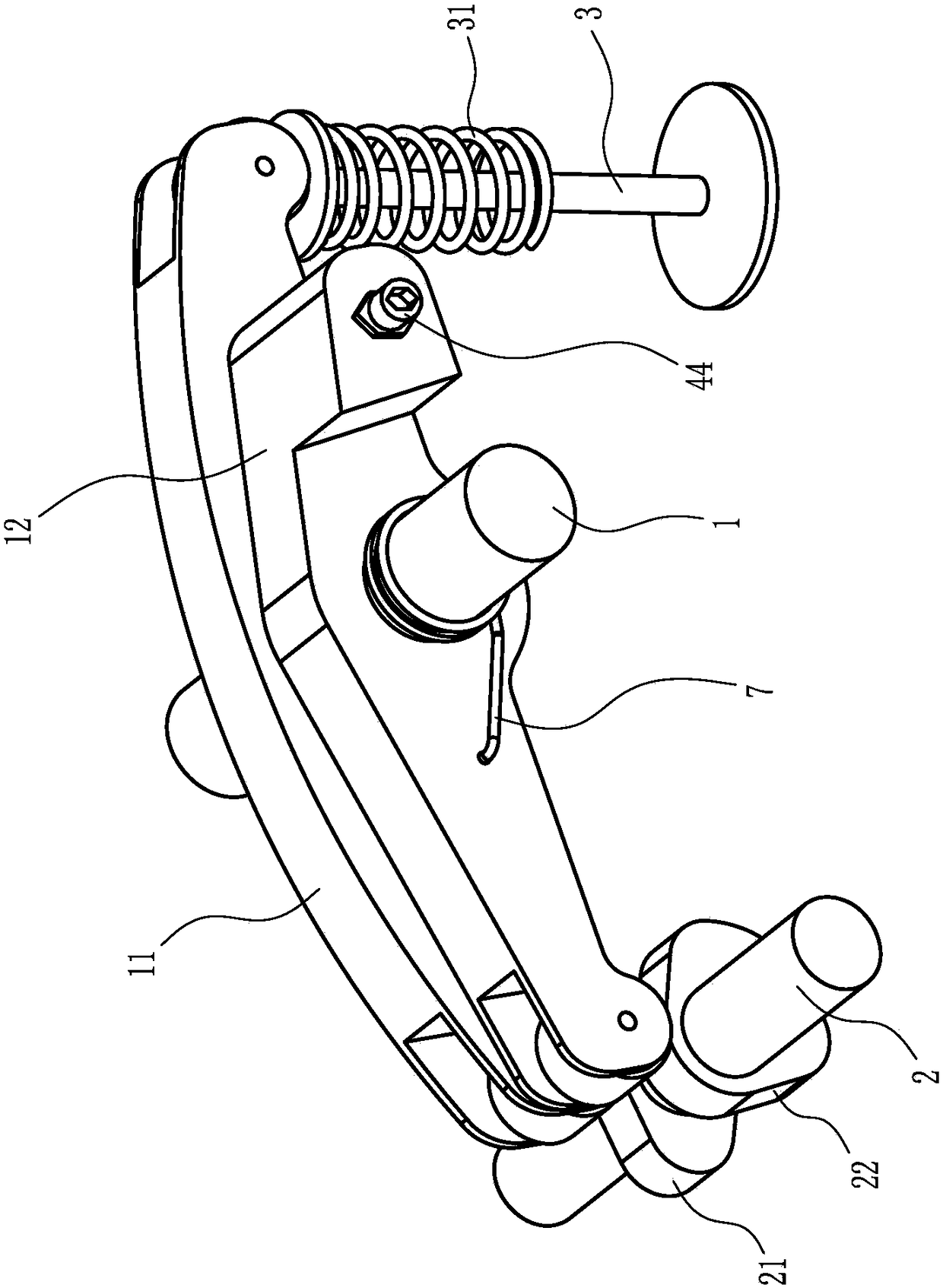

[0035] Embodiment two: if image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the connecting pin hole 5 is set on the main rocker arm 11, the continuous break control installation hole 4 is set on the auxiliary rocker arm 12, A magnetic connection pin 6 is slidably installed in the continuous control installation hole 4 . The anti-attraction force applying device includes a connecting pin protruding connecting spring 43 arranged in the continuous break control installation hole 4 and abutting against the end surface of the magnetic connecting pin 6 away from the main rocker arm 11 , the A spring abutment bolt 44 is threadedly mounted on the end of the continuous break control installation hole 4 away from the main rocker arm 11 , and the spring abutment bolt 44 in this embodiment can simultaneously adjust the preload of the connecting pin protruding from the connecting spring 43 force. The connecting pin breakage limiting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com