Noise diagnosis method for electrical equipment break-down arc

A technology of electrical equipment and diagnostic methods, applied in the direction of using electrical devices, using electromagnetic means, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of large external interference, time-consuming and labor-intensive sound wave signals, and reduce economic and life and property losses. , the effect of avoiding waste, reducing harm and chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Because the fault arc of electrical equipment generally has a relatively long partial discharge and glow discharge process before the severe discharge, the arc is not enough to cause serious damage to the circuit at this time, so it is a good time to warn the arc. Partial discharge will produce arc sound. The invention uses the detection of arc sound as the basis for fault arc detection and early warning, which is of great significance for building an online electrical equipment fault intelligent diagnosis and auxiliary decision-making system.

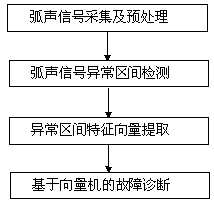

[0029] Such as figure 1 As shown, a noise diagnosis method of an electric equipment fault arc according to the present invention comprises the following steps:

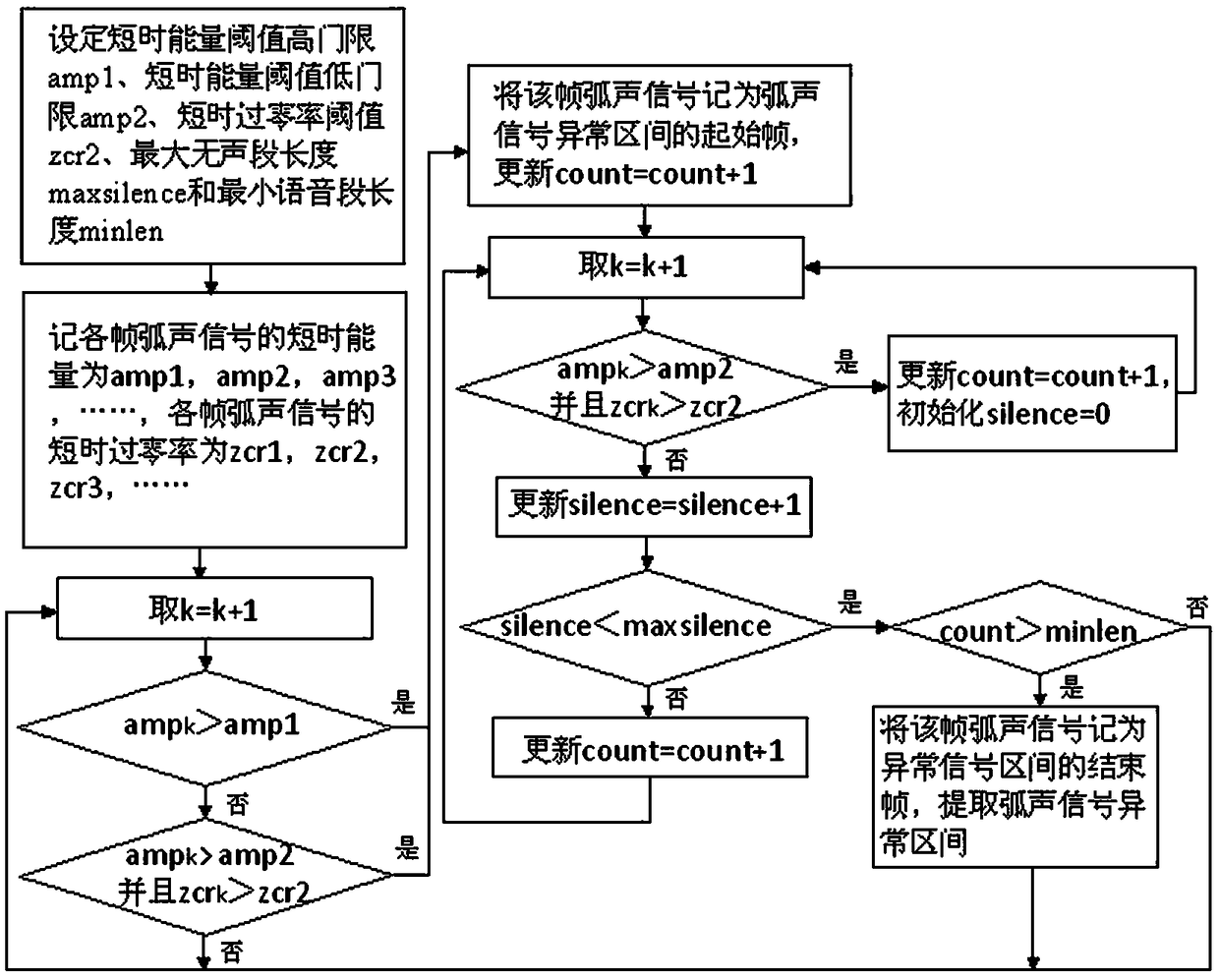

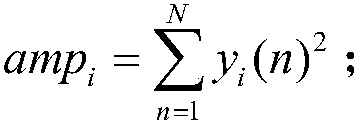

[0030] A. Acoustic signal collection and preprocessing: Audio sensors are used to collect the arcing signal of electrical equipment in operation, and pre-emphasis processing, FIR digital filtering and framing are performed on the arcing signal to obtain the arcing signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com