Rotating equipment for civil engine hole detection

A technology for rotating equipment and engines, which is used in engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of unstable torsion of artificial rotating blades, unfavorable rotational speed fluctuations, and impact on hole detection accuracy, and achieves a beneficial effect. Temporary overhaul, improve portability, and improve the effect of hole detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

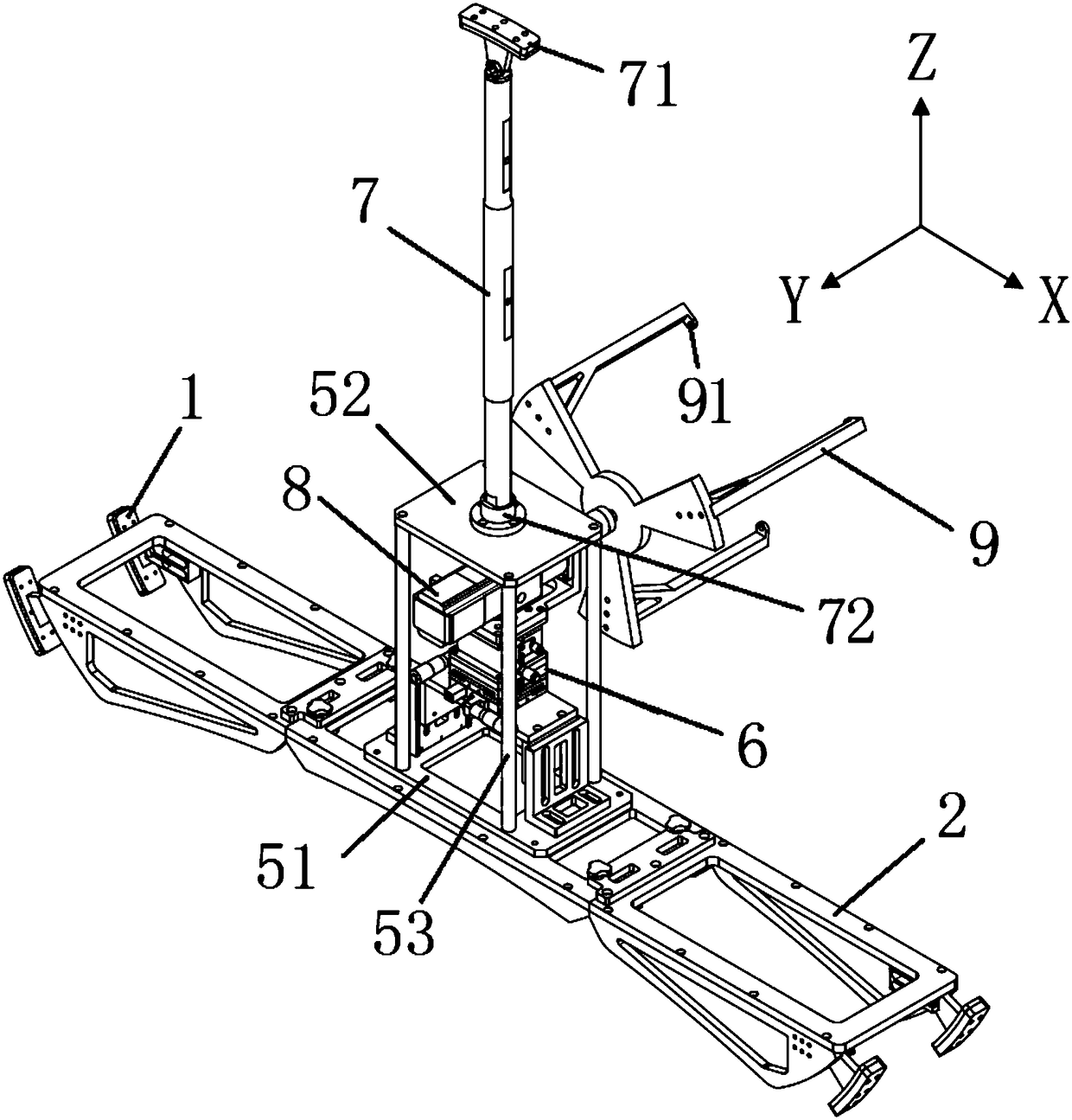

[0036] see Figure 1-8 , a rotating device for civil engine borehole detection, including: a support assembly, an XYZ axis adjustment mechanism 6, a drive mechanism 8, a rotating frame 9, and a telescopic support member 7.

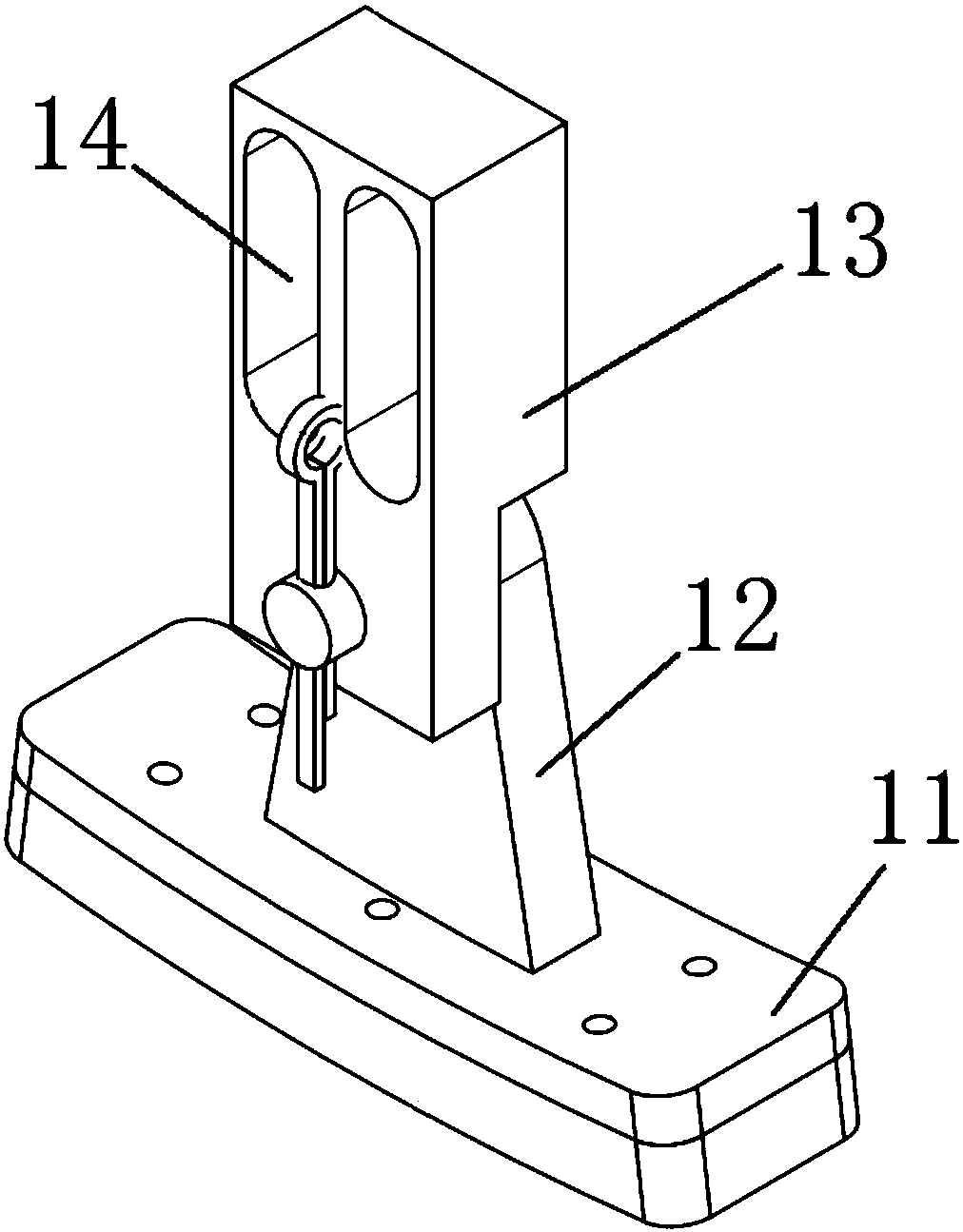

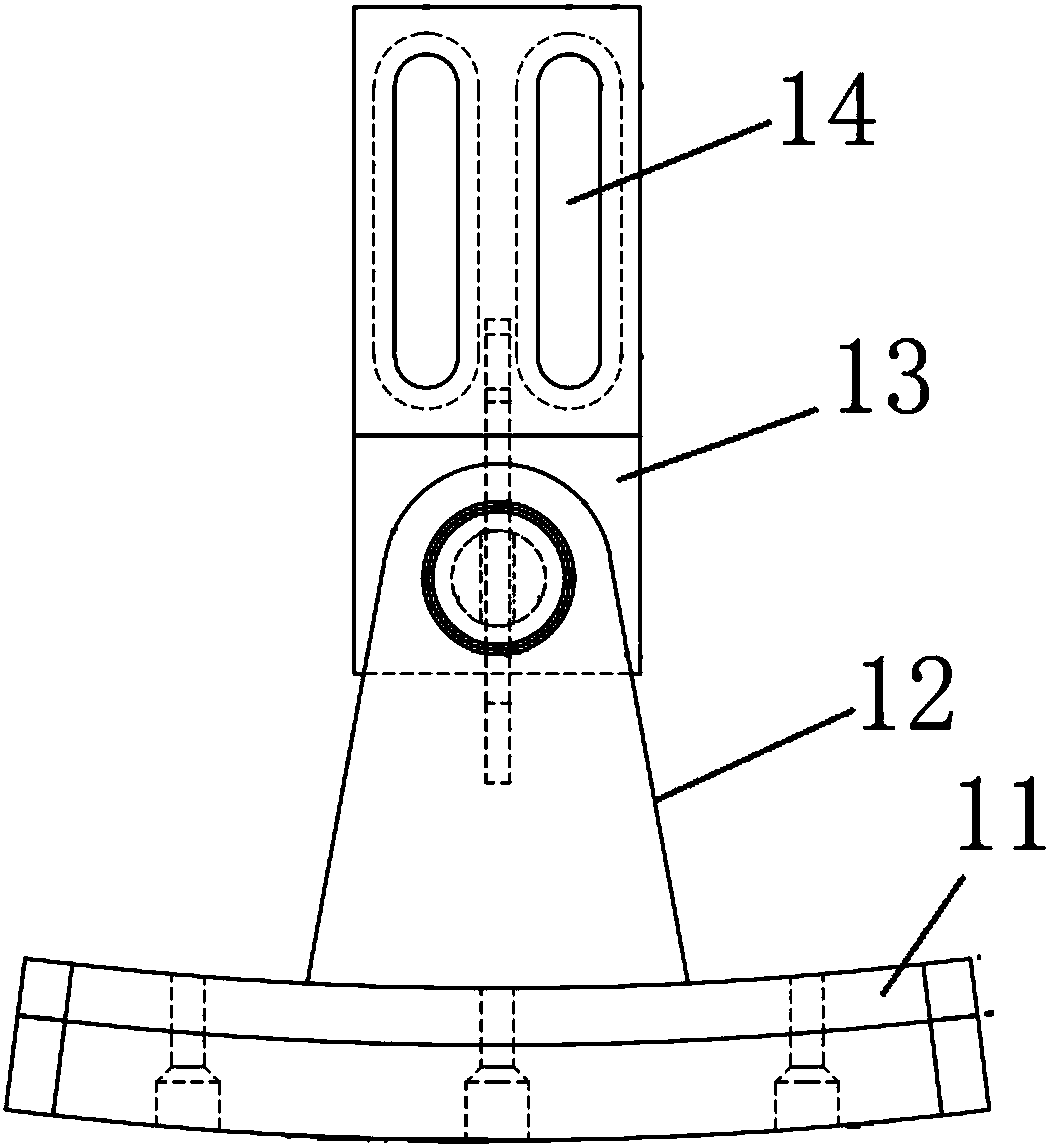

[0037] see Figure 1-3 , 8, a support assembly, its two ends are supported on the inner ring 101 of the front end of the engine blade; both ends of the support assembly are provided with an adjustment foot 1, and the adjustment foot 1 includes an adjustment foot arc block 11, and the adjustment The first connecting portion 12 fixedly connected to the foot arc-shaped block 11 and the second connecting portion 13 hinged or ball-jointed with the first connecting portion 12, the second connecting portion 13 is provided with a waist-shaped hole 14, the The adjusting foot 1 is fixed to the end of the support assembly through the waist-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com