X-ray sidescatter inspection of laminates

A technique of side scatter and x-rays, applied in the direction of material analysis using radiation, material analysis using wave/particle radiation, instruments, etc., can solve the complex, impossible inspection of composite parts, and the inability to determine the interior of composite parts with the naked eye Composition and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The figures and the following description illustrate certain exemplary embodiments of the present disclosure. It will thus be appreciated that those skilled in the art will be able to devise various arrangements which, although not explicitly described or shown herein, embody the principles of the disclosure and are included within the scope of the disclosure. . Furthermore, any examples described herein are intended to aid in understanding the principles of the disclosure, and are to be construed as not being limited to such specifically recited examples and conditions. As a result, the present disclosure is not limited to the specific embodiments or examples described below, but by the claims and their equivalents.

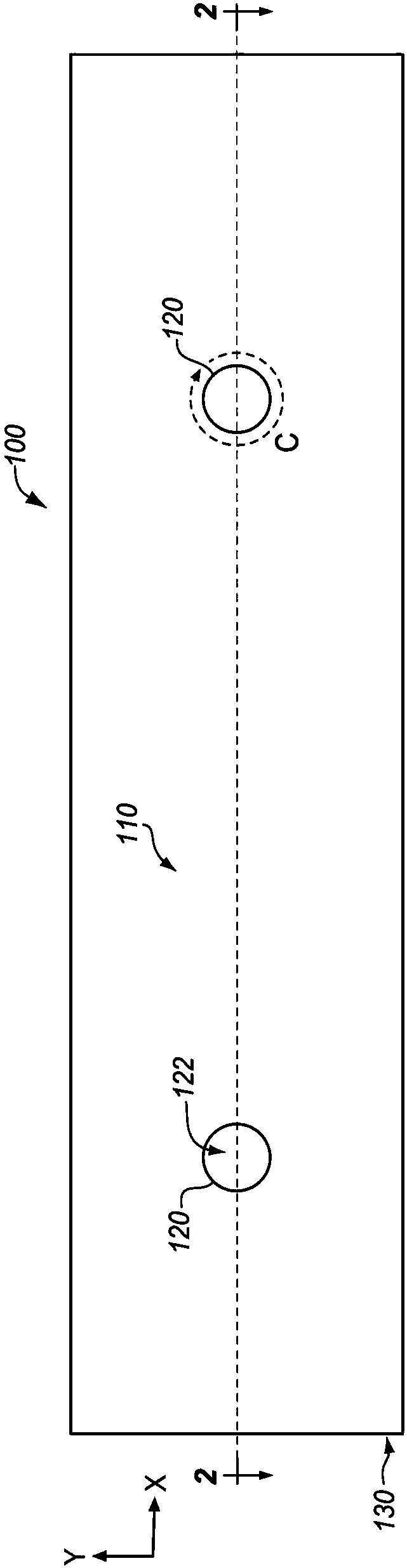

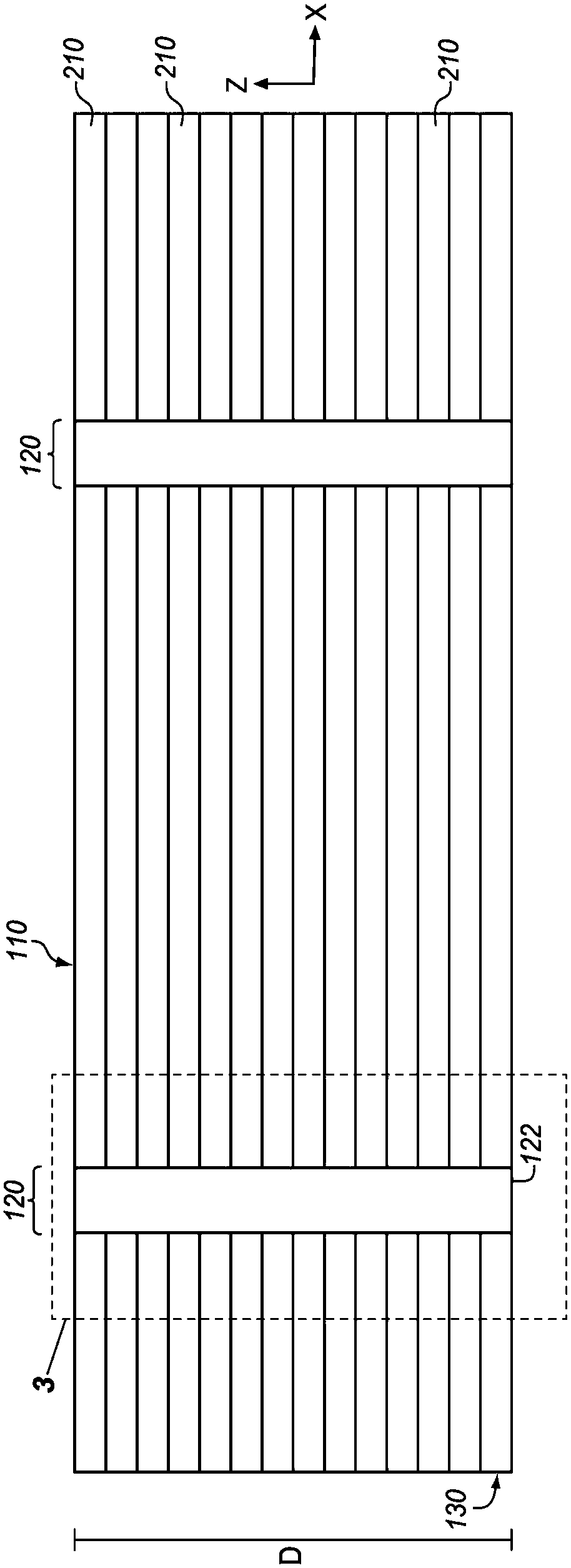

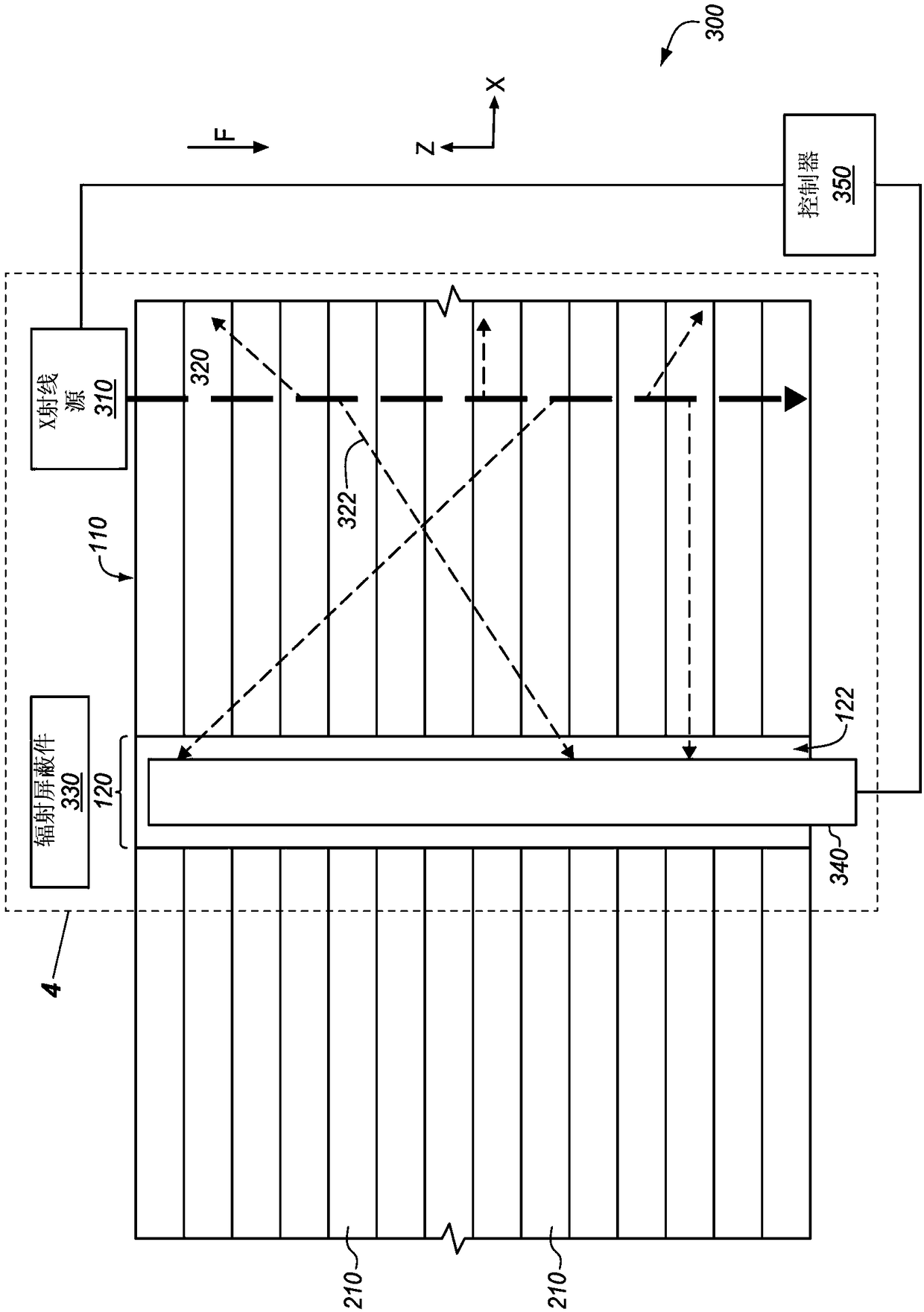

[0023] figure 1 and figure 2 is a diagram of a composite part 100 including a plurality of holes 120 in an exemplary embodiment. specifically, figure 1 is a view of the upper surface 110 of the part 100, however figure 2 is through figure 1 The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com