Amino-containing crosslinkable polyether sulfone as well as preparation method and applications thereof

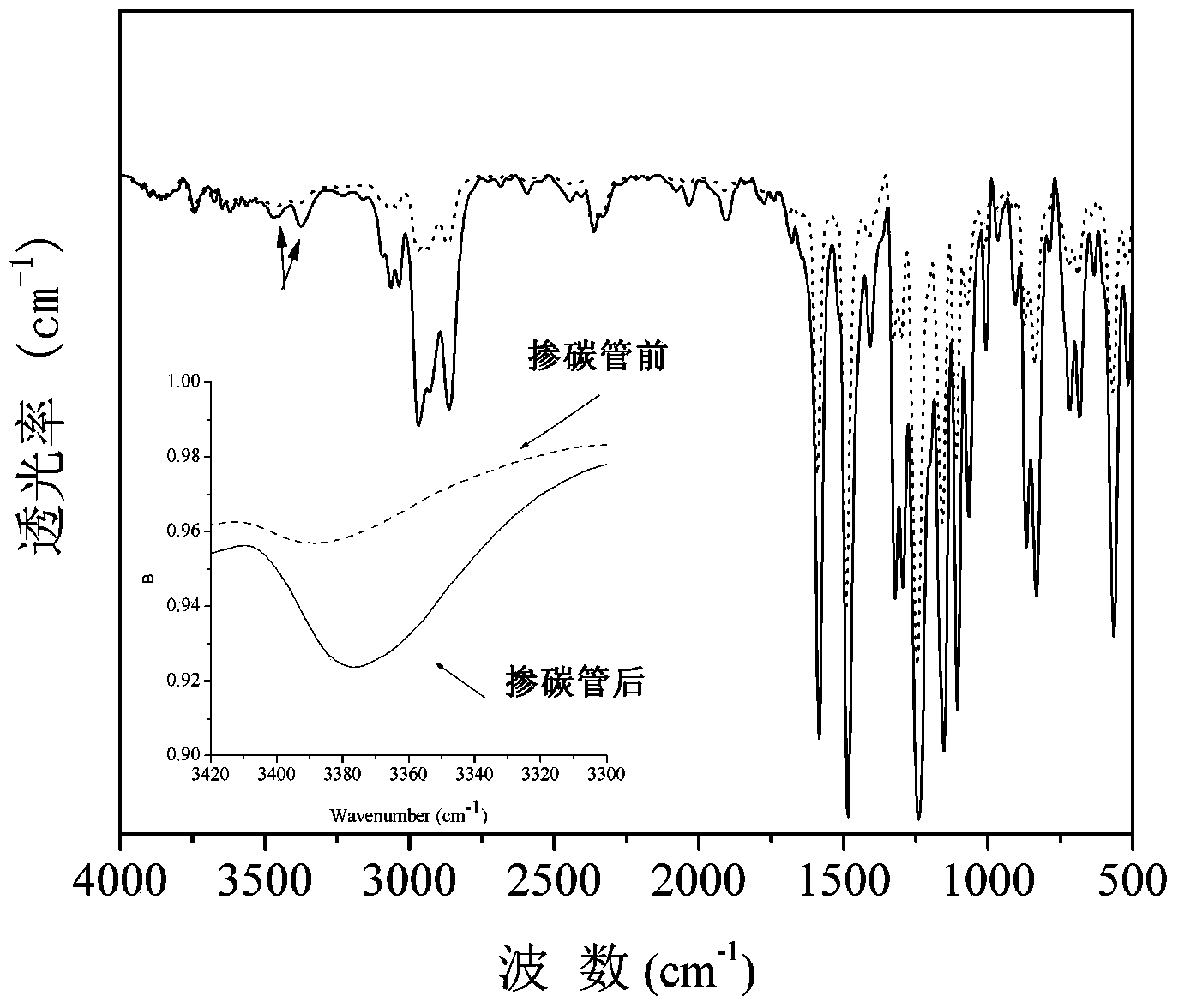

A polyaryl ether sulfone and amino group-containing technology, which is applied in the field of polymer carbon nanotube composite membrane and its preparation, can solve the problems that the gas permeability coefficient and selectivity coefficient cannot be improved at the same time, so as to broaden the scope of use and overcome the decline in selectivity , The effect of increasing the glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

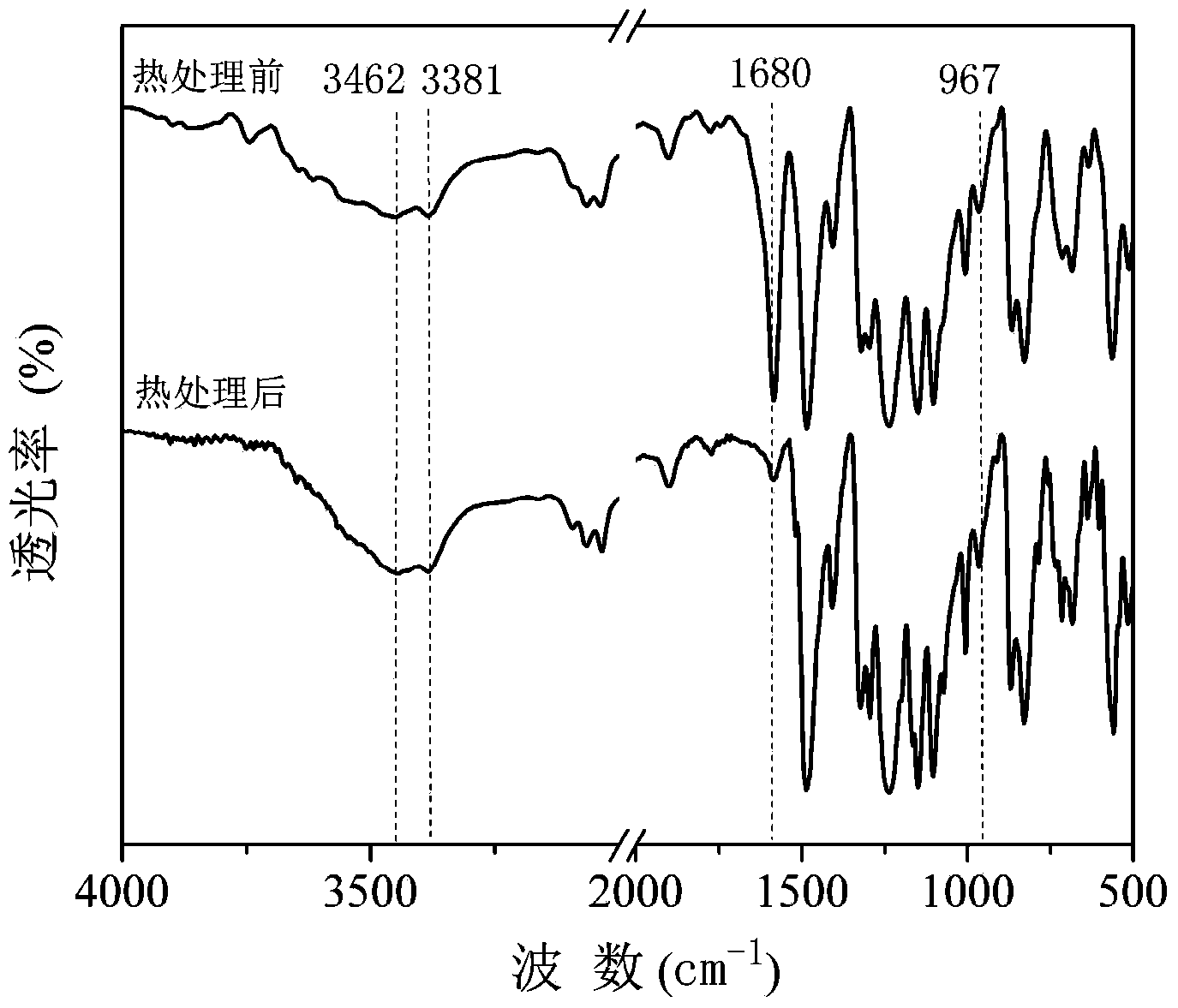

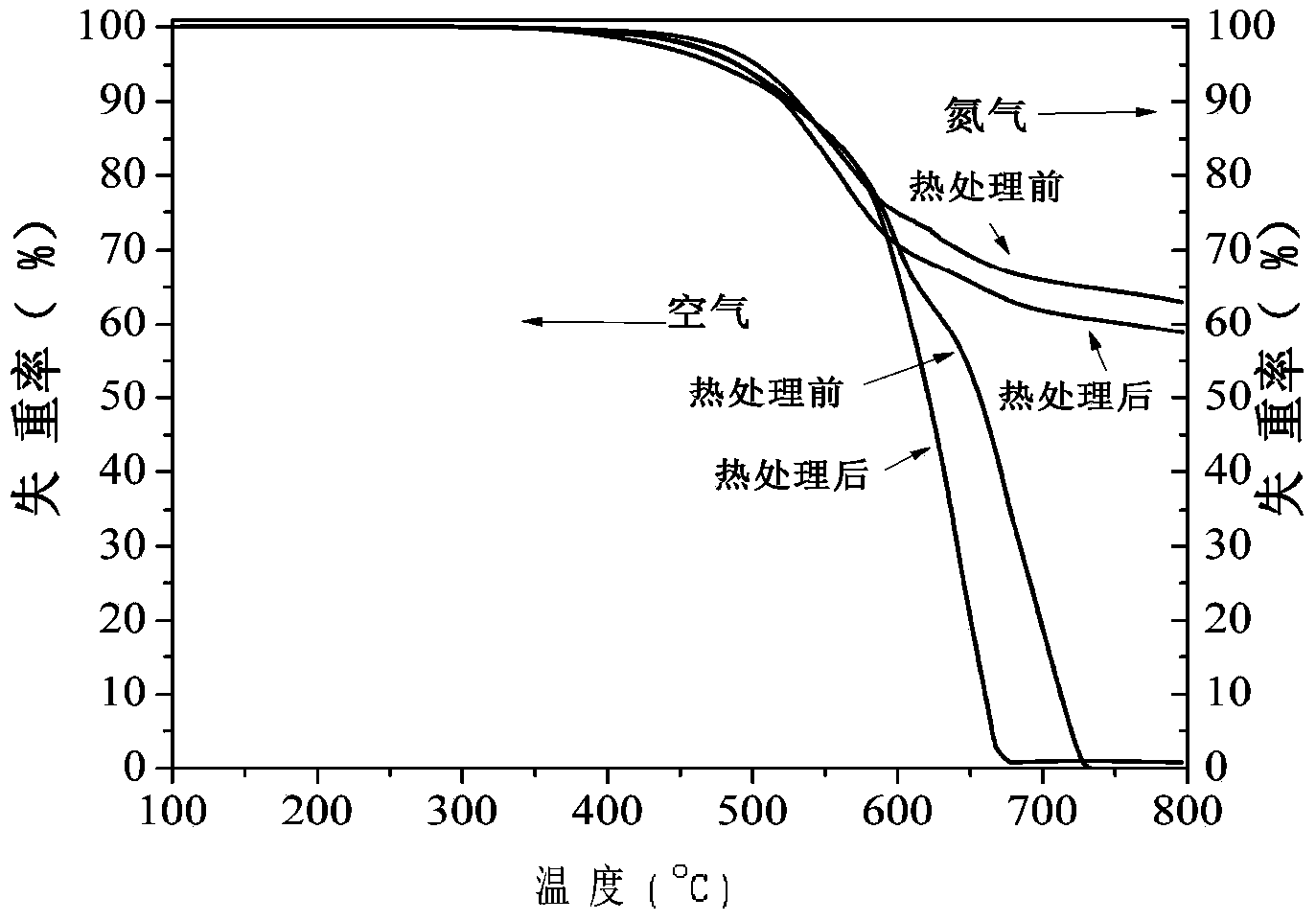

Embodiment 1

[0040] 0.002mol4-aminophenylhydroquinone, 0.001mol3,3'-diallylbiphenol, 0.017mol of biphenol, 0.0202mol4,4'-dichlorodiphenyl sulfone, 0.024mol Potassium carbonate water was added to a three-necked flask equipped with a mechanical stirrer, a thermometer, a water device and a condenser, and argon was introduced for protection. 24m1 sulfolane was added, with a solid content of 24.4%, and 10m1 toluene was added. After 3 hours with water at 140-150°C, the toluene was evaporated, and the temperature was raised to 165-170°C to continue the reaction for 5.5 hours. The product was poured into distilled water, filtered and crushed, washed with distilled water and ethanol for 3 times respectively, and vacuum-dried at 60°C for 12 hours to obtain 7.90 g of refined off-white copolymer powder with a yield of 96% and a polymer logarithmic ratio. The viscosity is 0.43dL / g. The results of DSC study showed that the glass transition temperature of the prepared cross-linkable polyaryl ether sulfo...

Embodiment 2

[0045] Embodiment 2 (copolymer A)

[0046] 0.002mol4-aminophenylhydroquinone, 0.002mol3,3'-diallylbiphenol, 0.016mol of biphenol, 0.0202mol4,4'-dichlorodiphenyl sulfone, 0.024mol Potassium carbonate water was added to a three-necked flask equipped with a mechanical stirrer, a thermometer, a water device and a condenser, and argon was introduced for protection. 24m1 sulfolane was added, with a solid content of 24.4%, and 10m1 toluene was added. After 3 hours with water at 140-150°C, the toluene was evaporated, and the temperature was raised to 165-170°C to continue the reaction for 5.5 hours. The product was poured into distilled water, filtered and crushed, washed with distilled water and ethanol for 3 times respectively, and vacuum-dried at 60°C for 12 hours to obtain a refined off-white copolymer powder with a yield of 95%. The logarithmic viscosity of the polymer was 0.35dL / g. The results of DSC study showed that the glass transition temperature of the prepared cross-link...

Embodiment 3

[0047] Embodiment 3 (copolymer B)

[0048] 0.002mol4-aminophenylhydroquinone, 0.003mol3,3'-diallylbiphenol, 0.015mol of biphenol, 0.0202mol4,4'-dichlorodiphenyl sulfone, 0.024mol Potassium carbonate water was added to a three-necked flask equipped with a mechanical stirrer, a thermometer, a water device and a condenser, and argon was introduced for protection. 24m1 sulfolane was added, with a solid content of 24.4%, and 10m1 toluene was added. After 3 hours with water at 140-150°C, the toluene was evaporated, and the temperature was raised to 165-170°C to continue the reaction for 5.5 hours. The product was poured into distilled water, filtered and crushed, washed with distilled water and ethanol for 3 times respectively, and vacuum-dried at 60°C for 12 hours to obtain a refined off-white copolymer powder with a yield of 96%. The polymer logarithmic viscosity was 0.43dL / g. The results of DSC study showed that the glass transition temperature of the prepared cross-linkable po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com