Square battery pack mounting structure

A technology for installing structures and battery packs, applied to battery pack parts, structural parts, circuits, etc., can solve problems such as troublesome disassembly, and achieve the effects of convenient composition, good use effect, and effective cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

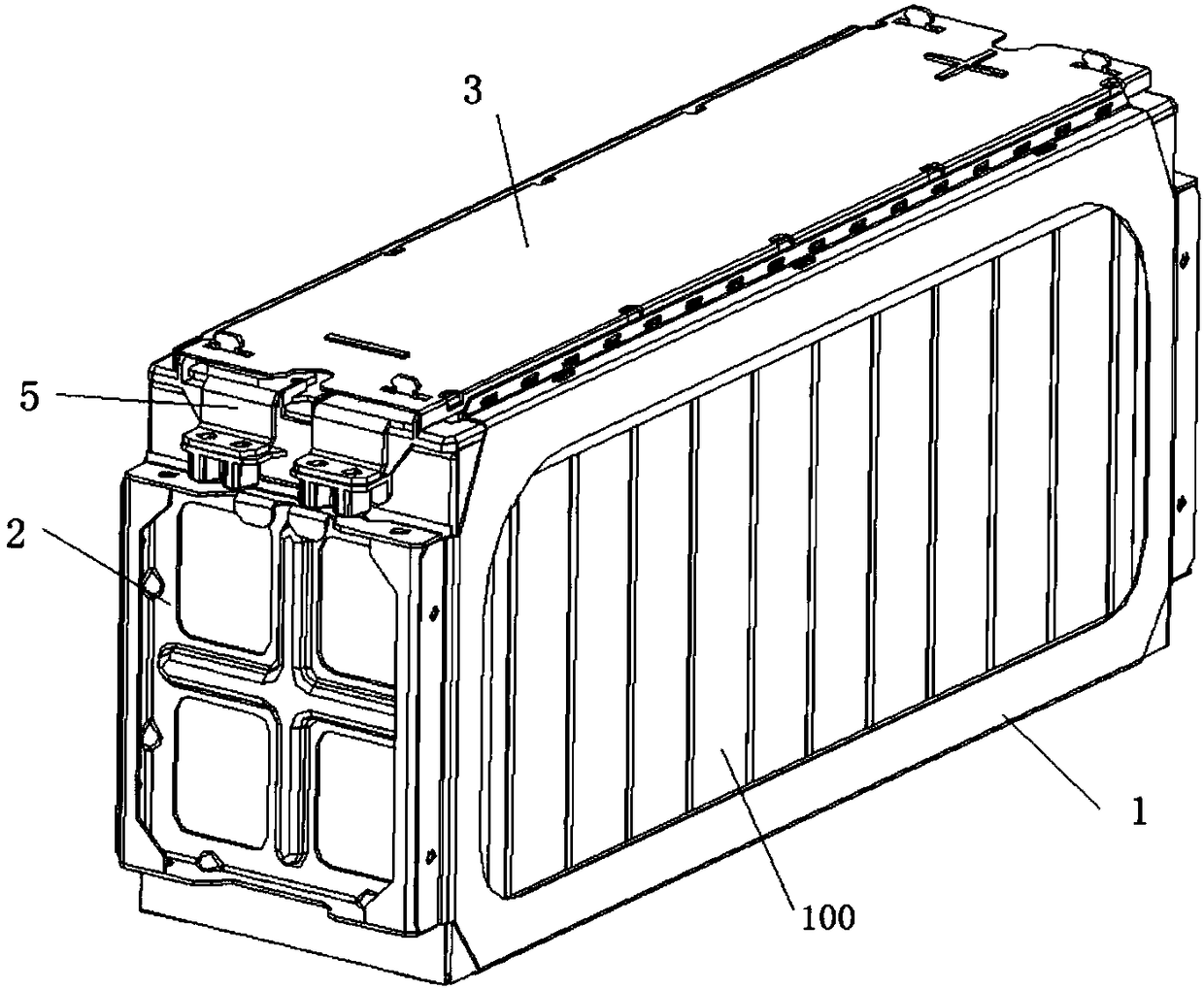

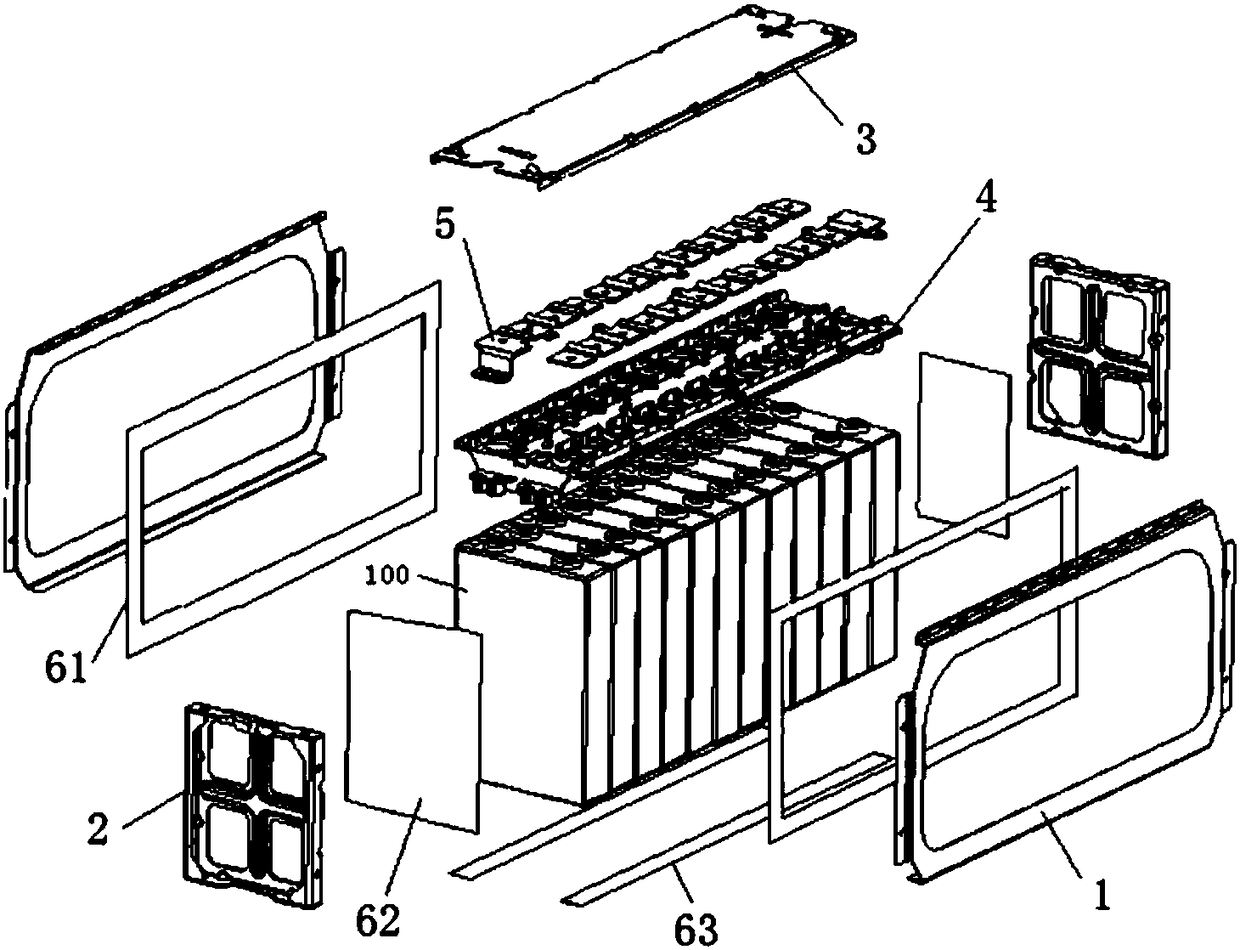

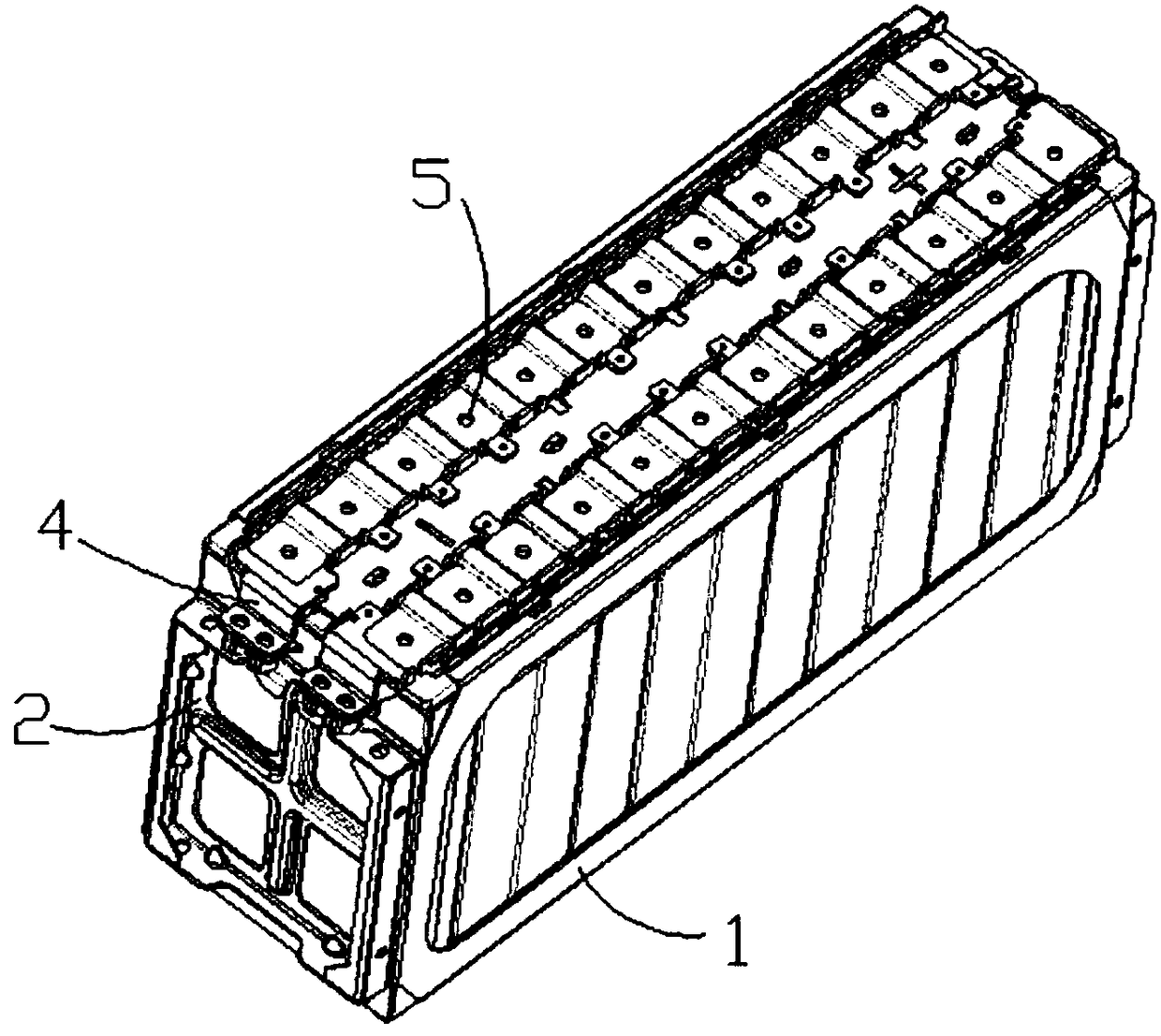

[0024] Such as figure 1 Such as Figure 7 , the present invention discloses a square battery pack installation structure, including a square battery cell 100 and an electrical connection plate 5, several square battery cells 100 are arranged side by side to form a battery pack structure, and the electrical connection plate 5 connects the electrodes of each square battery cell 100 , the installation structure for assembling the square cell 100 into a battery pack includes a side plate 1, an end plate 2, a cover plate 3, an electrical isolation plate 4, a first insulating plate 61, a second insulating plate 62 and a third insulating plate 63 , the two end plates 2 are placed on the front and rear sides of the battery pack, the electrical isolation plate 4 is placed on the upper end surface of the battery pack, and the electrical connection plate 5 is clamped on the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com