Food rolling machine

A technology of rolling machine and food, applied in the coating, application, food science and other directions of food, can solve the problems of time-consuming and laborious, affecting food health and hygiene, lubricating oil easily contaminating food, etc., to achieve simple operation, ensure health and hygiene, Easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

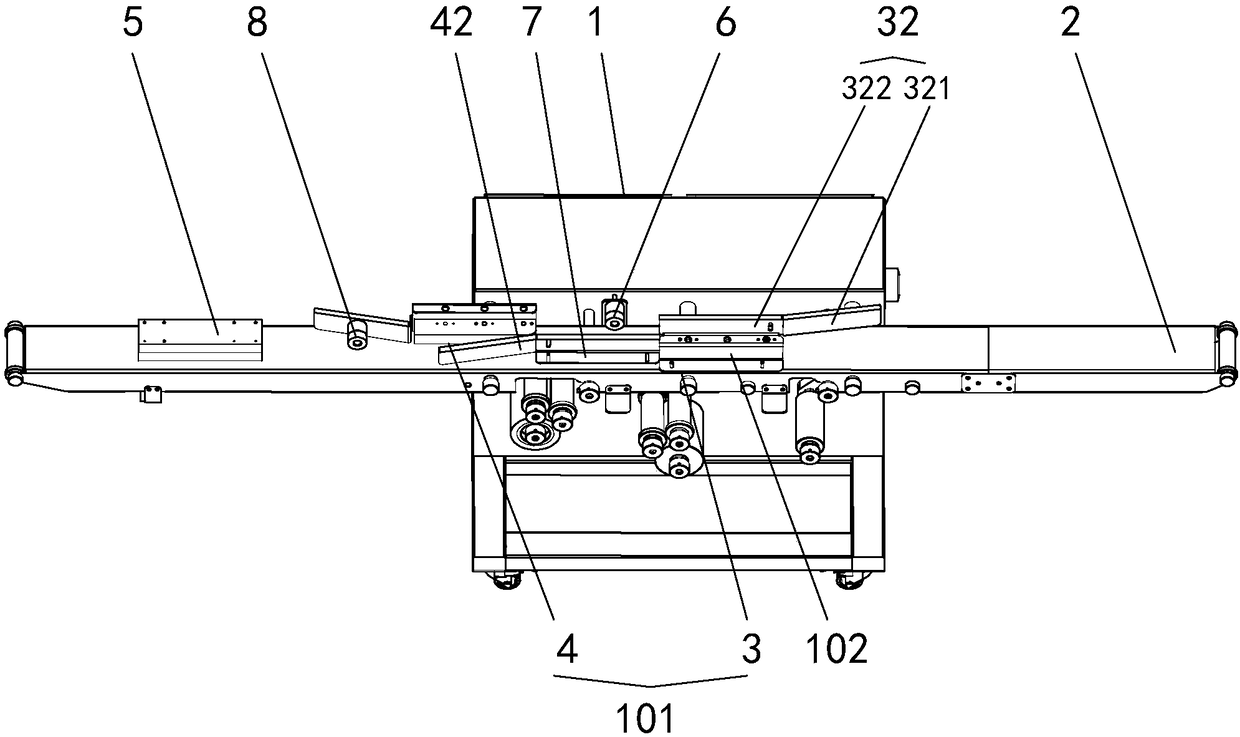

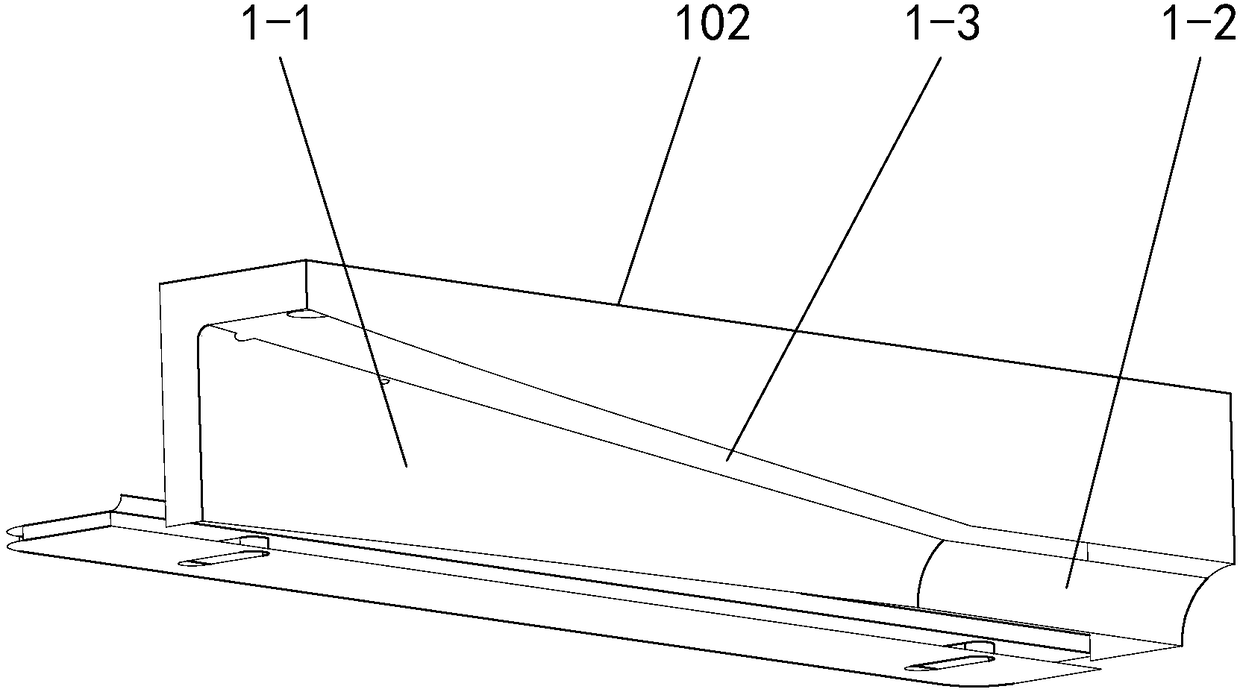

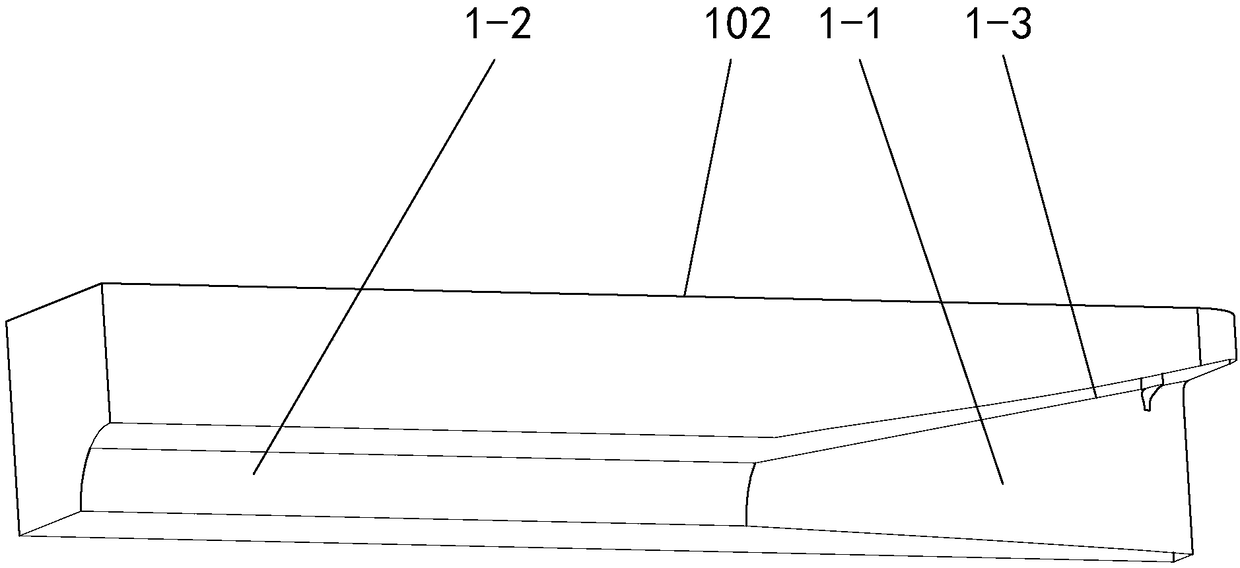

[0020] refer to Figure 1-Figure 5 , a food rolling machine, comprising a workbench 1, a flexible conveyor belt 2, a roll forming mechanism 101, and a forming mechanism 5 are arranged on the workbench 1, and the roll forming mechanism 101 is divided into a first roll mechanism 3 and a second roll mechanism 4, The rolling mechanism 101 is provided with a curling block for curling, and the inner side of the curling block 102 is provided with a vertical edge concave position 1-1, a curling arc concave position 1-3, and a vertical edge concave position 1-1 is provided with The top plate 1-3 of the oblique vertical side recess 1-2; the flexible conveyor belt 2 passes through the primary rolling mechanism 3, the secondary rolling mechanism 4, and the forming mechanism 5 from right to left, between the primary rolling mechanism 3 and the secondary rolling mechanism 4 There is a conveyor belt positioning guide wheel 6, and a parallel baffle 7 is provided on the opposite side of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com