A peu mounting bracket assembly for a hybrid vehicle

A hybrid vehicle and mounting bracket technology, which is applied in vehicle parts, transportation and packaging, circuits or fluid pipelines, etc., can solve the problems of substandard strength and mode of the bracket, breakage, etc., to save layout space and simplify the assembly process. , the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

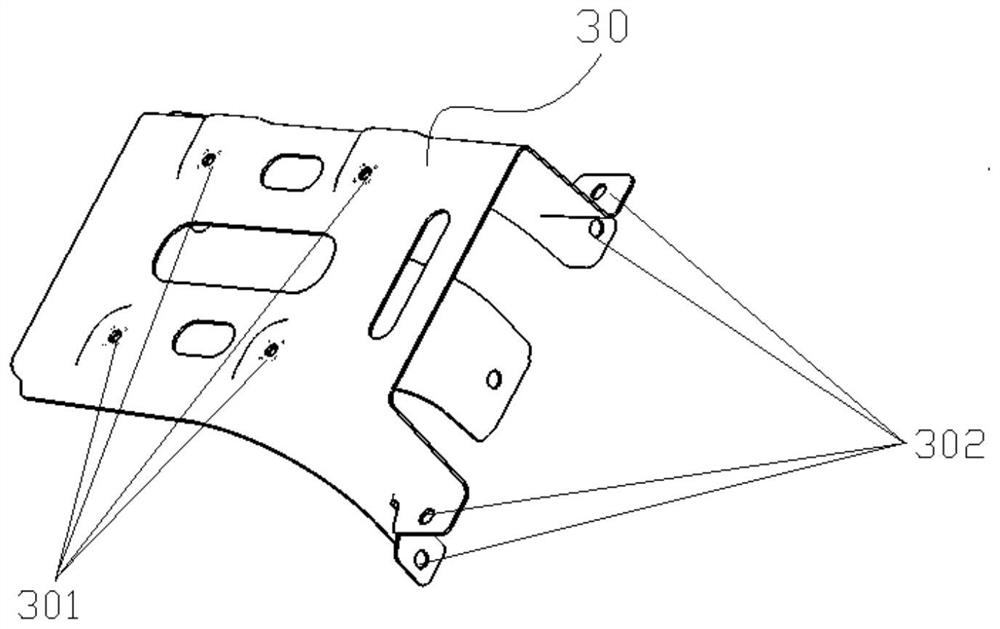

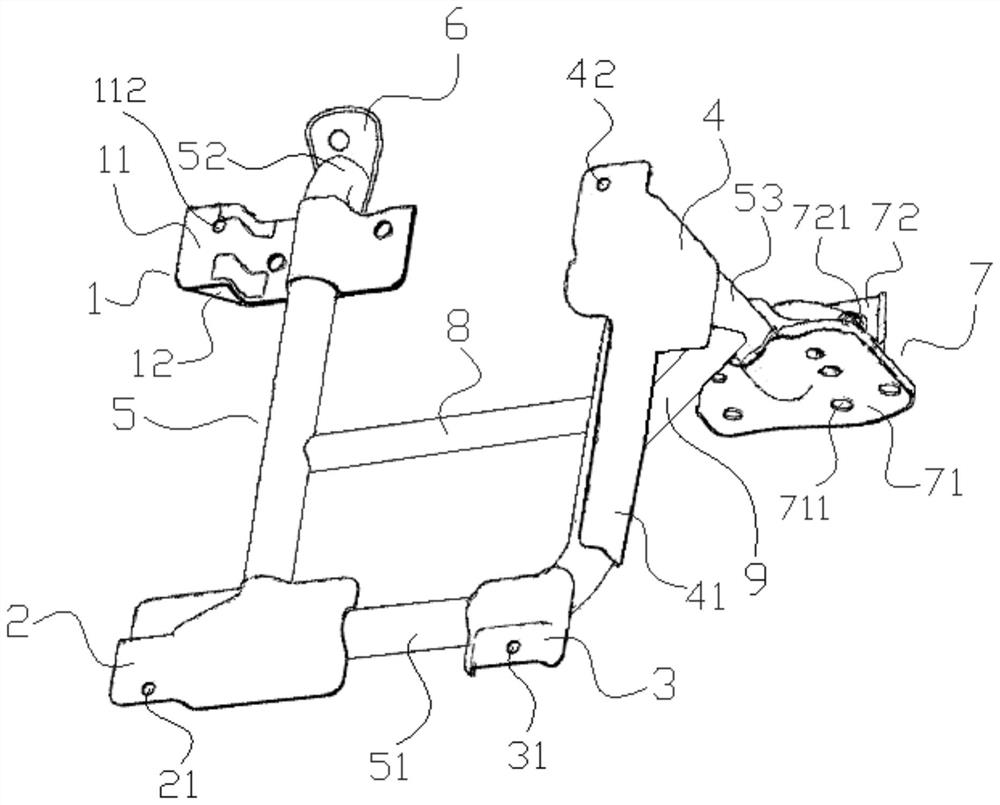

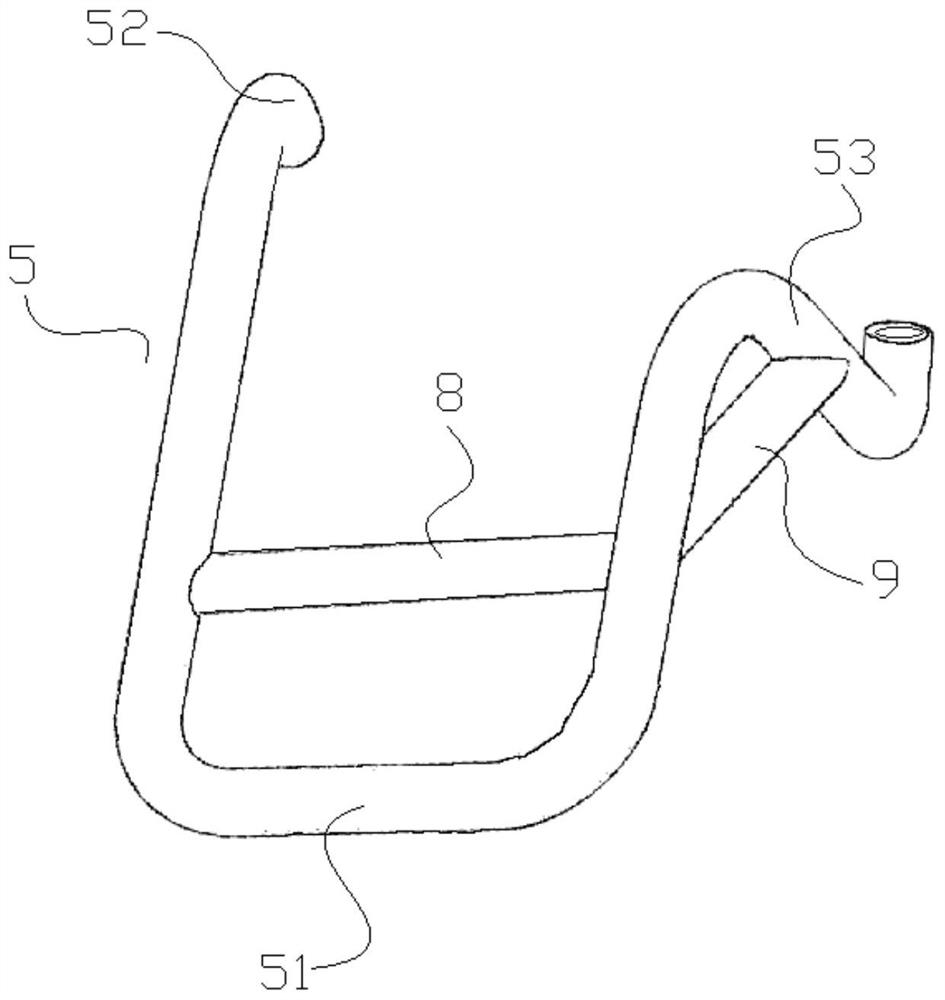

[0021] like Figures 2 to 5 The PEU mounting bracket assembly shown, including support frame 5, PEU first foot point mounting bracket 1, PEU second pin mounting bracket 2, PEU third foot point mounting bracket 3, PEU fourth foot point Mounting bracket 4, wheel drum pins mounting bracket 6, the stringed beam point mounting bracket 7, the first reinforcing steel pipe 8 and the second reinforcing steel pipe 9. The support frame 5 is bent by the steel pipe, has a first support arm 51 in which a U-shaped first support arm 51 is connected to the second support arm 52 having a "┓"-shaped shape on the left end of the first support arm 51 and the right end of the first support arm 51. The third support arm 53 in which the first reinforcing steel pipe 8 is welded to the left side of the first support arm 51, and the other end and the right portion of the first support arm 51, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com