Die-cutting machine split type electric cabinet box installing structure with high shock resistance

A die-cutting machine and shock-resistant technology, applied in the direction of connecting components, mechanical equipment, pins, etc., can solve the problems of falling off terminals, vibration of the body, easy loosening of electrical equipment, etc., to improve work stability and service life, reduce The effect of vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

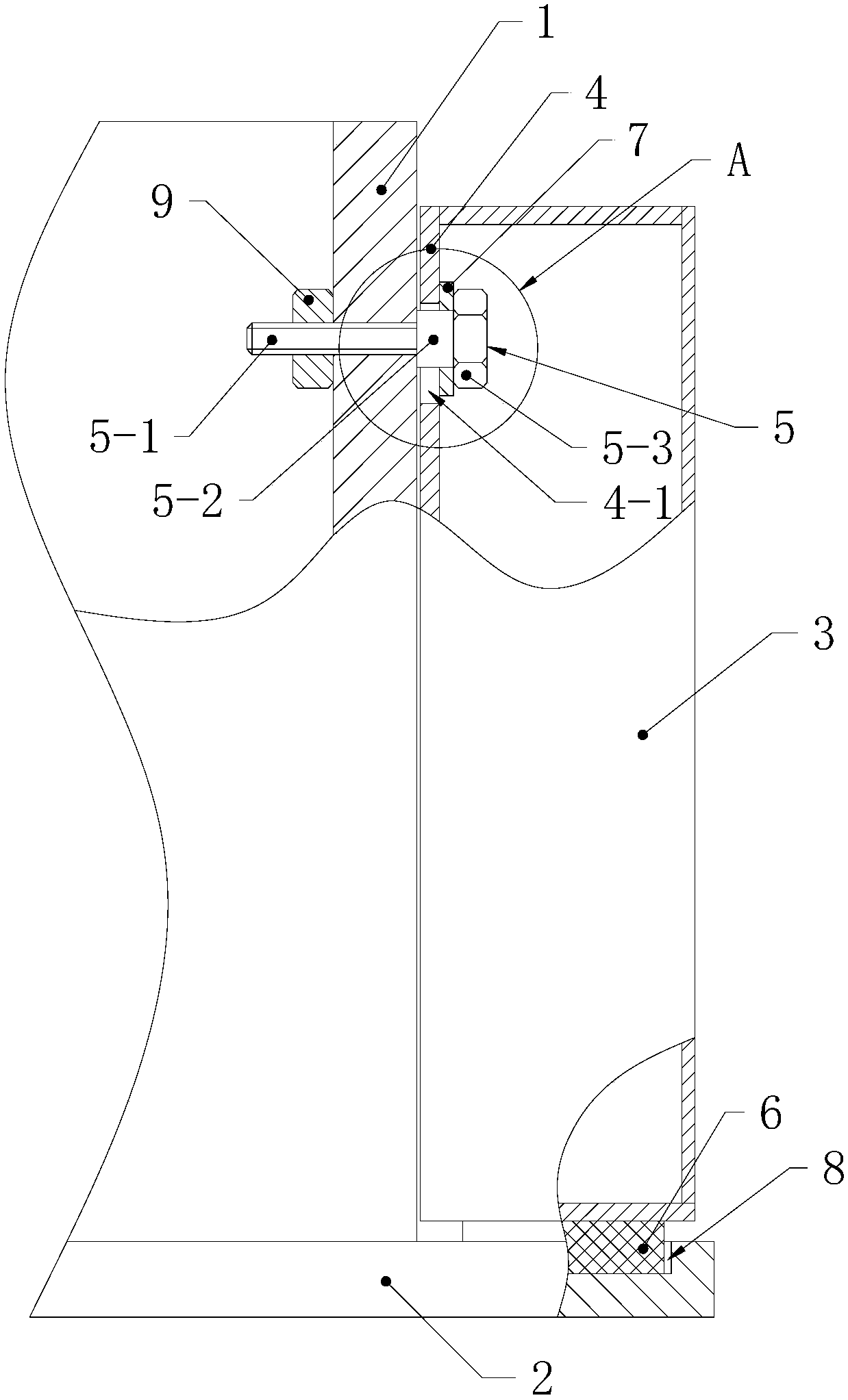

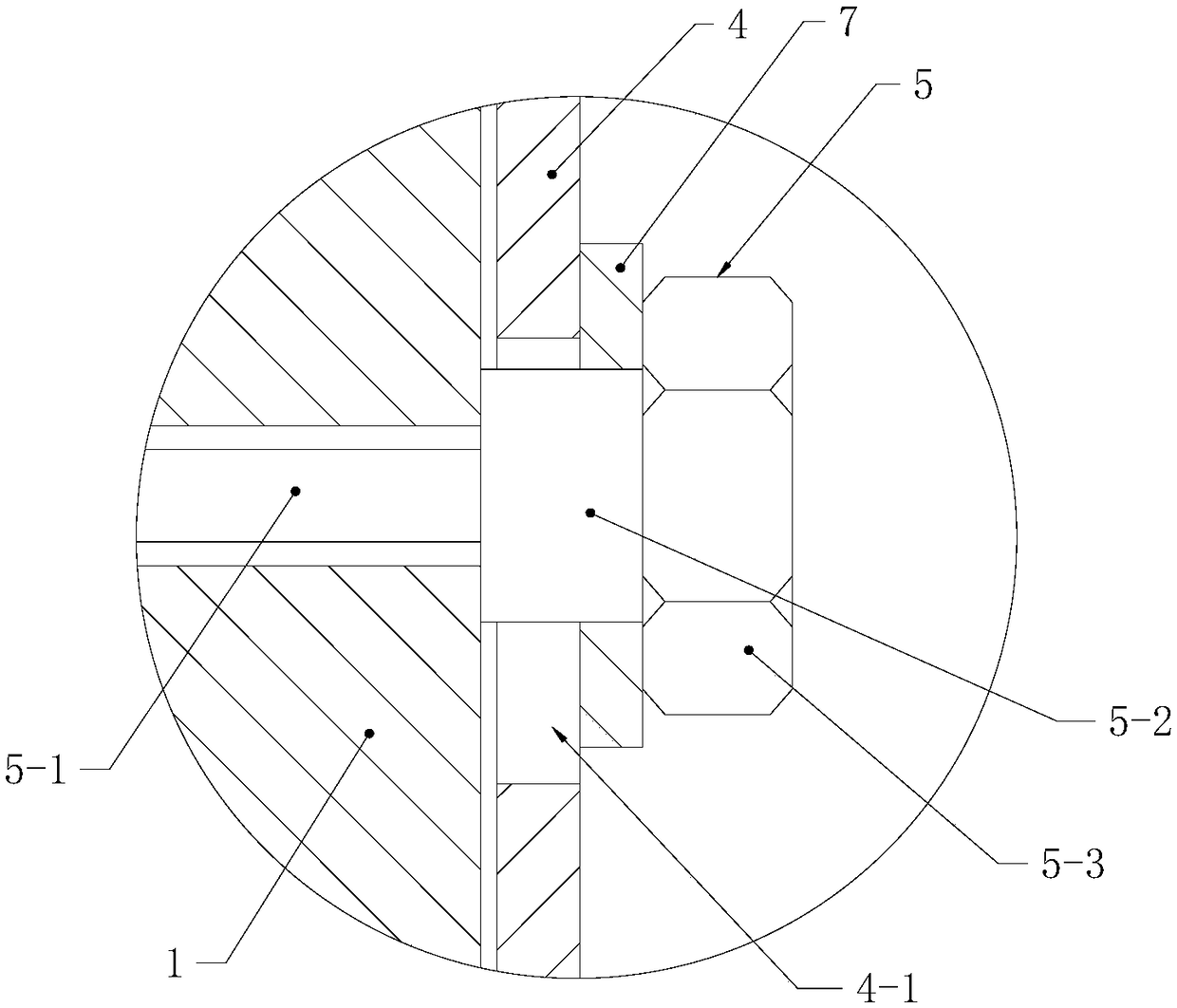

[0014] Such as figure 1 and figure 2 The high shock resistance die-cutting machine split-type electrical cabinet installation structure shown includes a die-cutting machine wall plate 1 and a bottom plate 2, the bottom of the electric cabinet box 3 rests on the bottom plate 2, and the back plate 4 of the electric cabinet box 3 is abutted on the On the wallboard 1, it is connected with the wallboard 1 by a bolt 5, wherein the bolt 5 includes a screw section 5-1, a support section 5-2, and a nut 5-3, wherein the support section 5-2 forms a cylinder Body, coaxially connected between the screw section 5-1 and the nut 5-3, the diameter of the support section 5-2 is between the diameter of the screw section 5-1 and the outer diameter of the nut 5-3, the wallboard 1 is provided with a plurality of threaded holes 1-1 matching with the screw section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com