Efficient motor lead winding equipment

A technology of winding equipment and lead wire, applied in the field of high-efficiency motor lead wire winding equipment, can solve the problems of poor winding quality, deviation of winding positioning accuracy, complicated structure of winding machine, etc. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

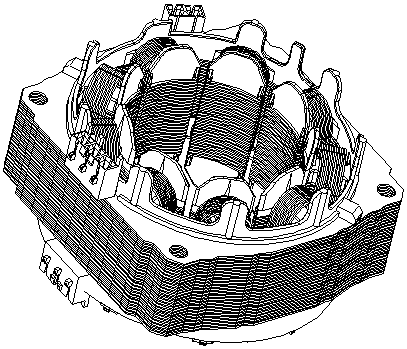

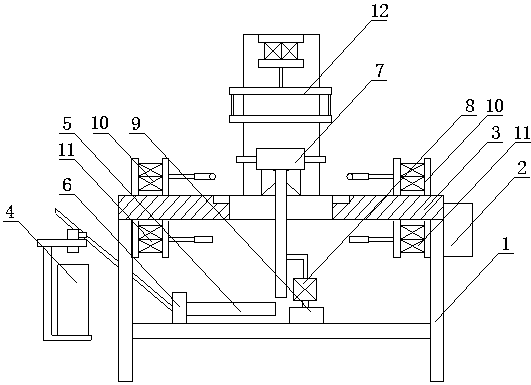

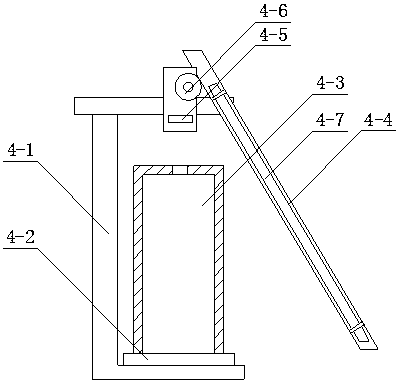

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a high-efficiency motor lead wire winding equipment described in this embodiment includes a frame 1, a controller 2, a workbench 3, a material placement mechanism 4, a delivery pipe 5, a lead wire tension regulator 6, and a rotating and revolving assembly 7. Motor 8, lifting assembly 9, positioning hook wire mechanism 10, shearing mechanism 11 and pressing mechanism 12, workbench 3 is fixed on the frame 1, a through hole is provided on the upper surface of workbench 3, and The periphery of the through hole extends downwards with positioning slots; the lower part of the through hole facing the workbench 3 is connected with the rotating and revolving assembly 7 through the motor 8, and the motor 8 is connected with the lifting assembly 9, so that the rotating and revolving assembly 7 is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com