Thermoforming apparatus and thermoforming method

A technology of thermoforming and conveying equipment, which is applied in the field of thermoforming equipment and can solve problems such as multiple heating times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

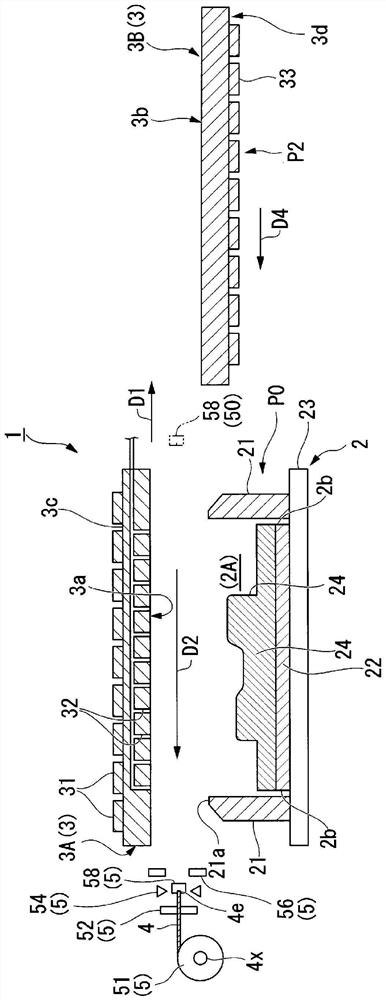

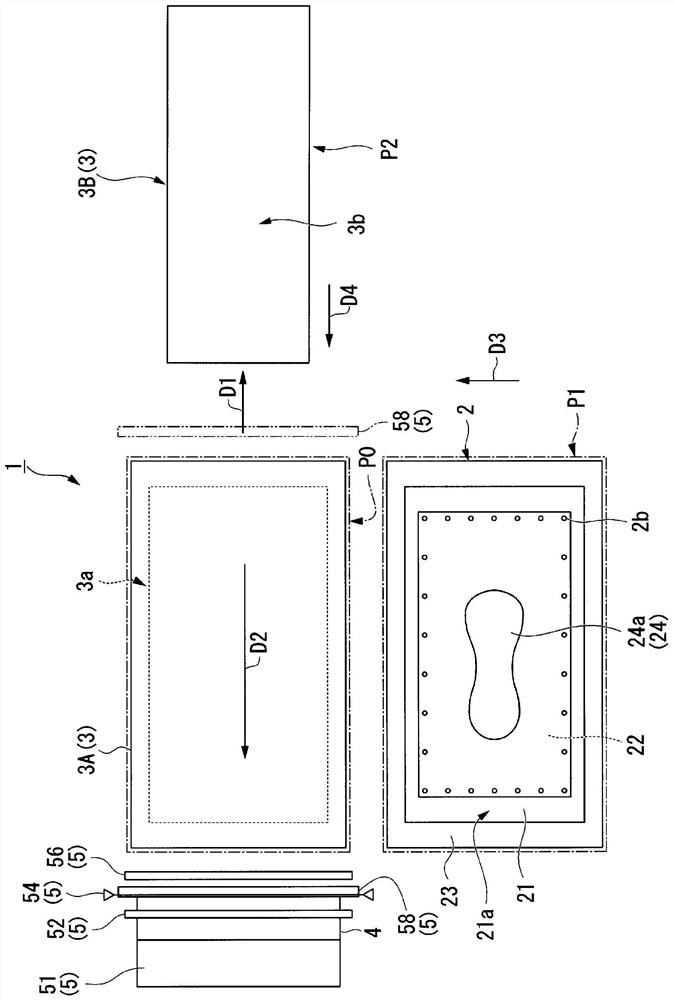

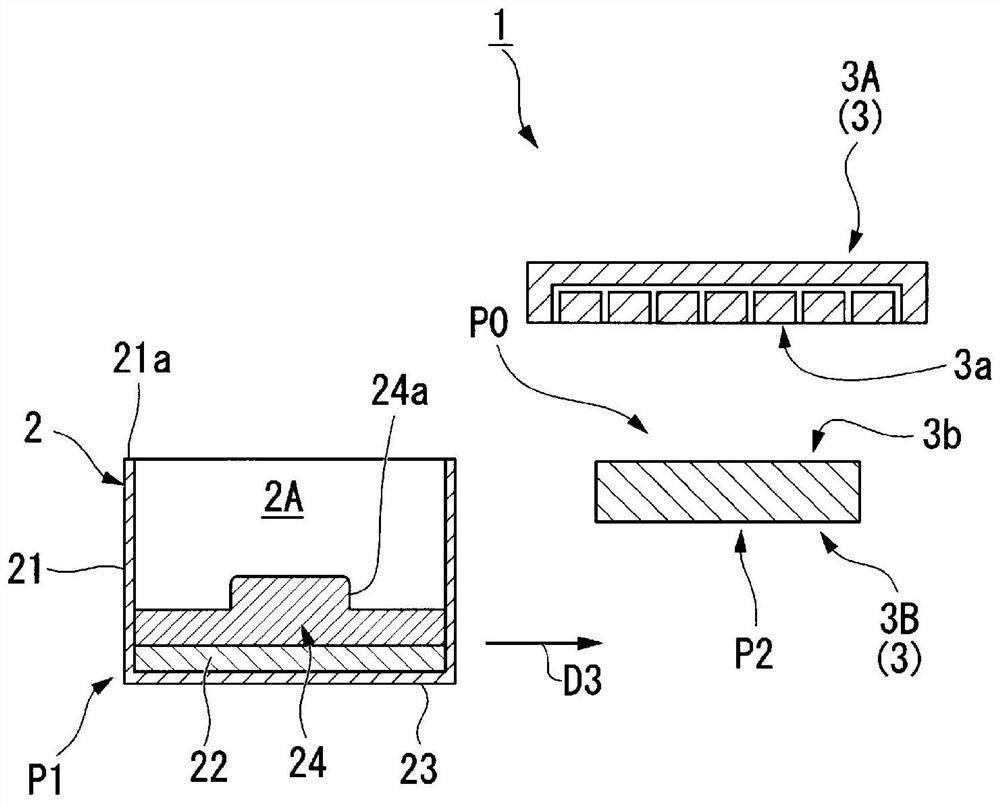

[0057] Next, a thermoforming apparatus and a thermoforming method according to an embodiment of the present invention will be described based on the drawings.

[0058] Such as Figure 1 to Figure 3 As shown, the thermoforming apparatus 1 according to this embodiment adopts a hot plate heating system. The thermoforming apparatus 1 is an apparatus for covering the surface 6 a of a molding base 6 with a sheet 4 heated and softened by heating plates 3 (upper heating plate 3A, lower heating plate 3B). The heating plates 3 (upper heating plate 3A, lower heating plate 3B) are provided as a pair of upper and lower heating plates. Molding substrate 6 such as Figure 7 As shown, it is arranged in the chamber 2A of the lower frame 2 (substrate supply unit).

[0059] Among them, as thermoformed product 6A (refer to Figure 9 ), which can be used as parts with inner and outer surfaces such as automobile parts. The thermoformed product 6A is a thermoformed product obtained by adsorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com