Method for producing fuel composition and for operating internal combustion engine

A fuel composition and internal combustion engine technology, applied in the field of producing cheap fuel composition, can solve the problems of synthetic gas consumption and expensive, and achieve the effect of improving flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

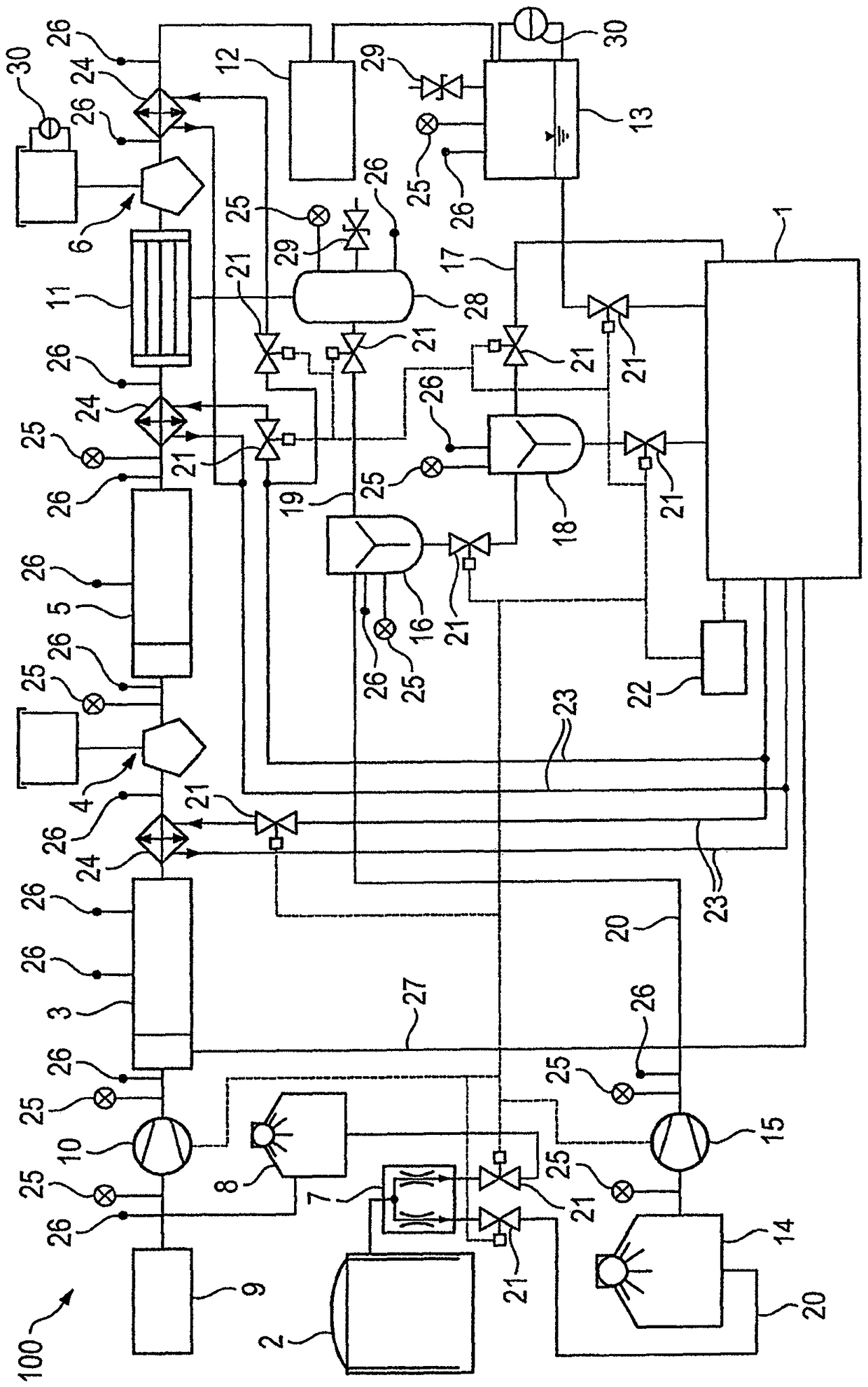

[0024] figure 1Relevant components of a system 100 are shown, which are suitable for operating an internal combustion engine according to an advantageous development of the method. The device includes internal combustion engine 1, special gas source 2, reformer 3, CO 2 Separator 4 , DME generating device 5 and methanol separator 6 . First, a special gas containing a combustible substance is supplied from the special gas source 2 . Suitable special gases include waste and associated gases from the chemical industry and raw material production (e.g. from refining), wood gas, conversion gas, pyrolysis gas, biogas and pit gas, coke oven gas, landfill gas, biogas , sewage gas, natural gas, flare gas, shale gas, city gas, propane, butane, associated gases formed in the production of steel and iron (for example: iron furnace gas, blast furnace gas, etc.) composed mixture. The special gas is conducted through a flow splitter 7, which separates the special gas into a first part and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com