Controlled stopping method for textile machine and textile machine stopped by this process

A technology for textile machines and control equipment, applied in the direction of controlling multiple DC motors, controlling multiple AC motors, motor control, etc., can solve the problems of reduction, unstable control of intermediate circuit voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

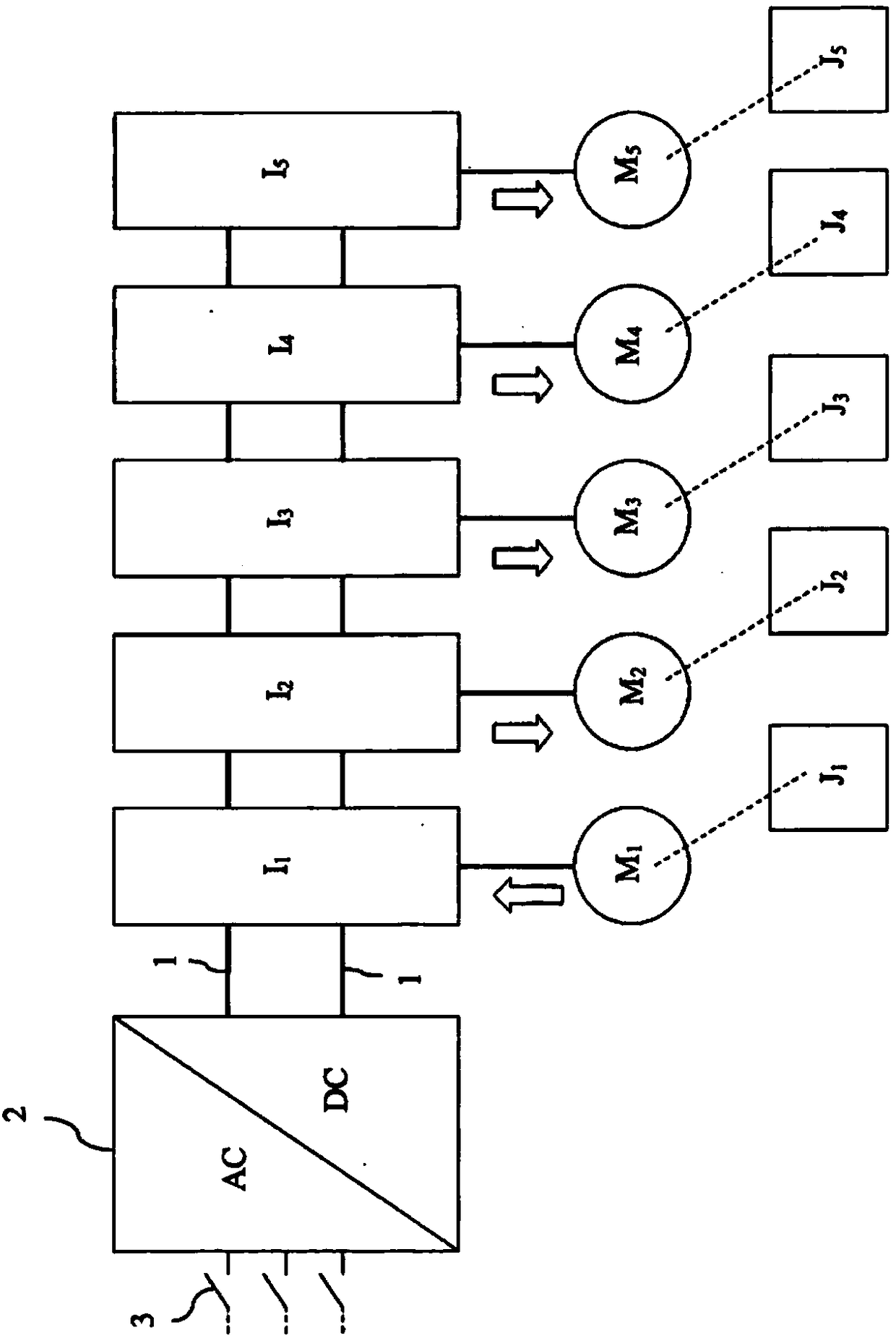

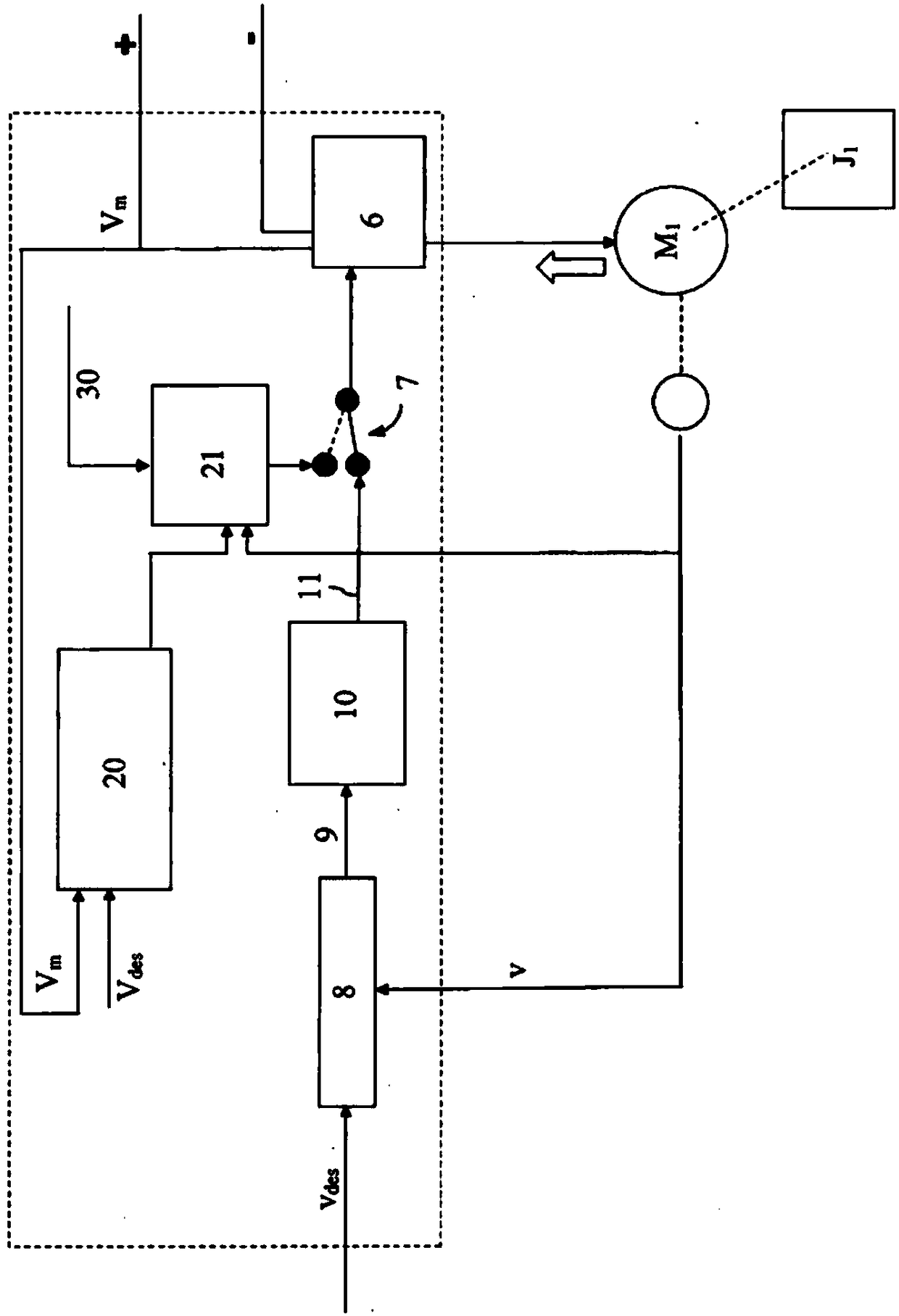

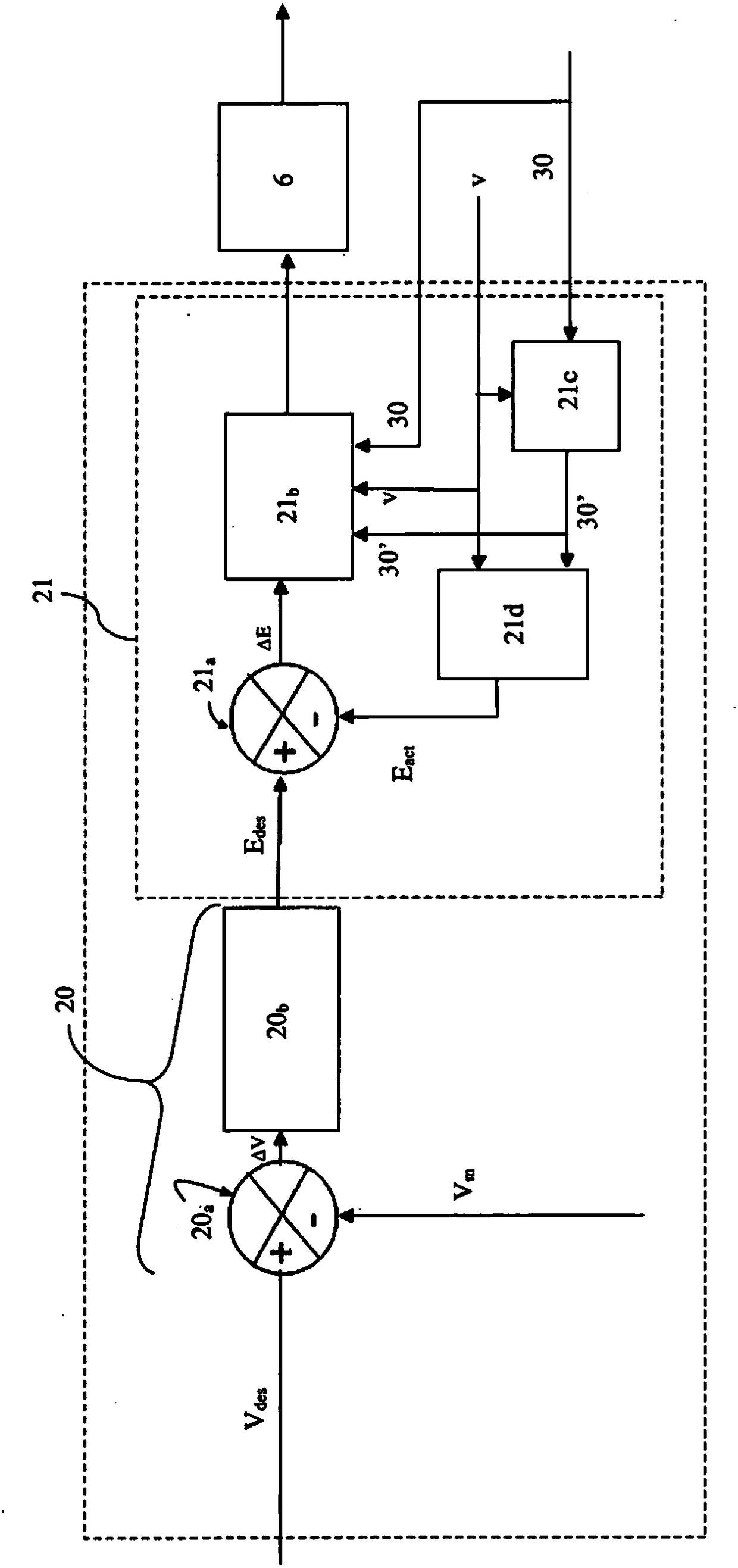

[0062] figure 1 The textile machine according to the invention in the schematically shown embodiment has a motor (M 1 , M 2 , M 3 , M 4 , M 5 ) driven by 5 axes. Each axis has its own inertia (J 1 、J 2 、J 3 、J 4 、J 5 ). through a separate motor controller (I 1 ), (I 2 ), (I 3 ), (I 4 ), (I 5 ) controls the motor and said motor is connected to a common intermediate voltage circuit (1) or "common DC bus". In normal operating conditions, they are supplied with power from the mains source via the AC / DC converter (2) and the switching device (3).

[0063] Via the motor on the left hand side (M 1 ) is driven by the axis with the highest energy content or the energy-dominant axis. On a knitting machine, this is the spindle. The word "axis" is used not only to mean the axis itself, but also all parts that are set in motion by this axis. "Energy content" means kinetic energy, said kinetic energy of motion with rotation being the inertia of the shaft according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com