Wheat no-tillage planter

A seeder, wheat technology, applied in fertilizers and seeding equipment, agricultural machinery and implements, shovels, etc., can solve the problems of wet and sticky soil, easy clogging of seed discharge openings, lack of seedlings and ridge breakage, etc., to reduce forward resistance, improve The effect of permeability and reducing the amount of ground breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

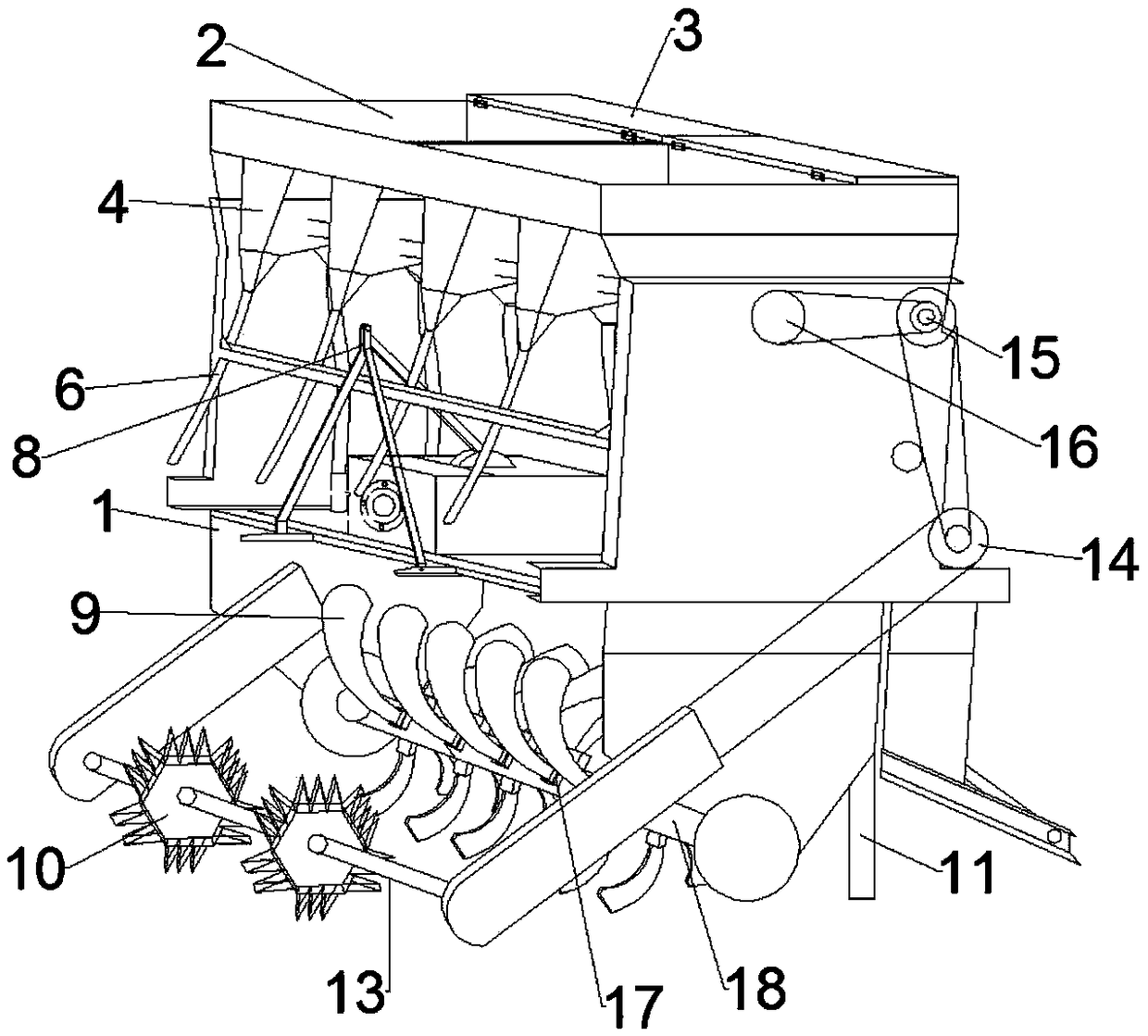

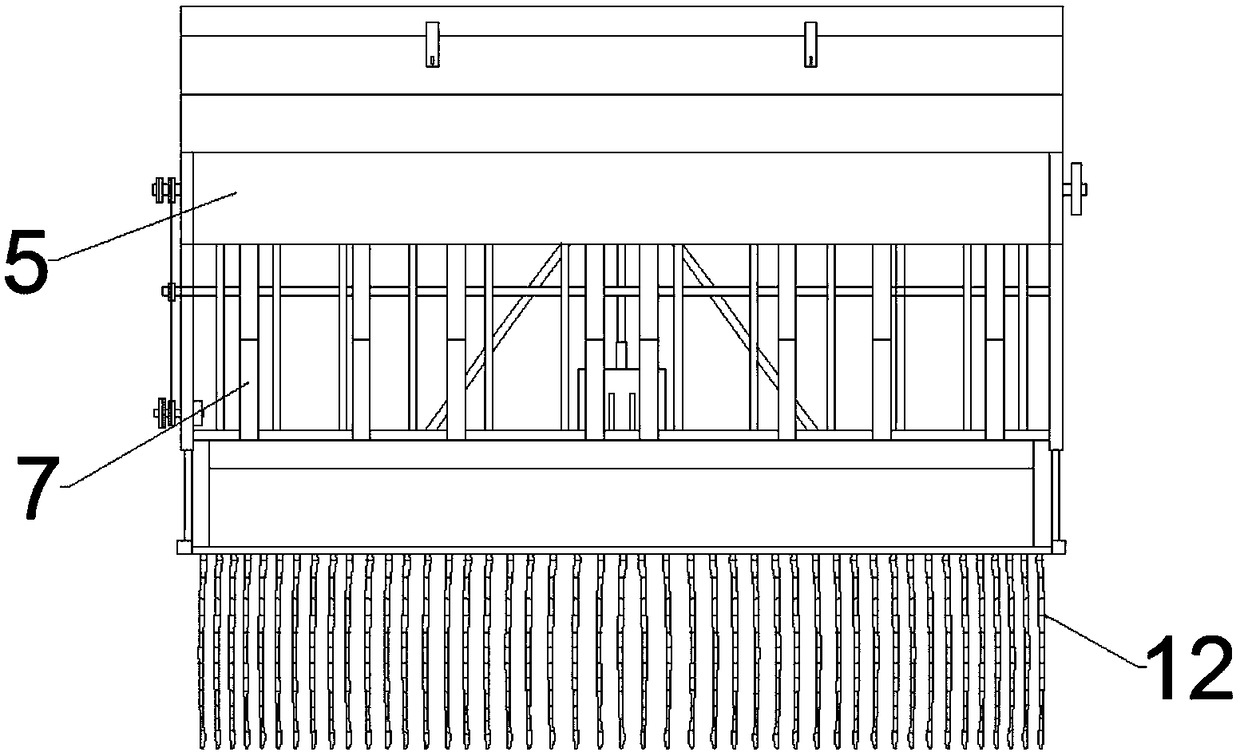

[0028] like figure 1 As shown, a wheat no-tillage seeder of the present invention includes a frame 1, a fertilizer box 2, a seed box 3, a fertilizer discharge device 4, a seed meter 5, a fertilizer discharge pipe 6, a seed meter 7, and an on-hook part 8 , Rotary tiller 9.

[0029] Fertilizer box 2 and seed box 3 are all arranged on the top of frame 1, and fertilizer box 2 is positioned at the front side of seed box 3, and fertilizer discharger 4 is installed in fertilizer box 2, and seed metering device 5 is installed in seed box 3.

[0030] The fertilizer discharger 4 is composed of a shaft, multiple sets of fertilizer discharge wheels assembled on the shaft, and a hopper corresponding to the fertilizer discharge wheel set. Its specific structure is like a rotary fertilization seeder, application number 201521034141.1, and the fertilizer discharger has 4 shafts. One side of the bar is equipped with a fertilizer discharge wheel 16; the structure and principle of the seed mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com