Environment-friendly automatic paint spraying equipment and application method thereof

An automatic painting and environment-friendly technology, which is applied in the direction of spraying booths, spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of not meeting the needs and environmental protection requirements, low painting efficiency, uneven spraying, etc., and achieve spraying effect Good, high spraying efficiency, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

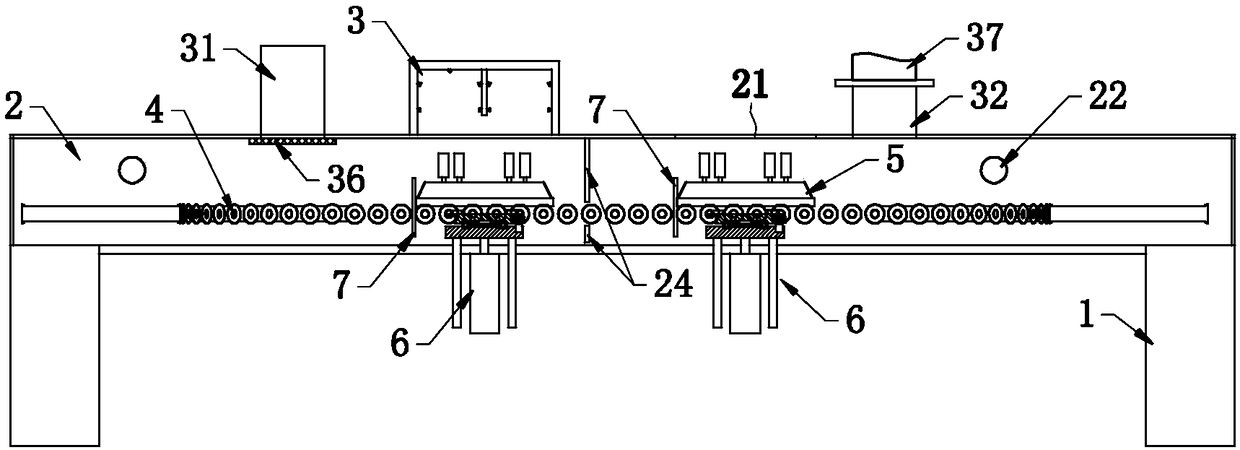

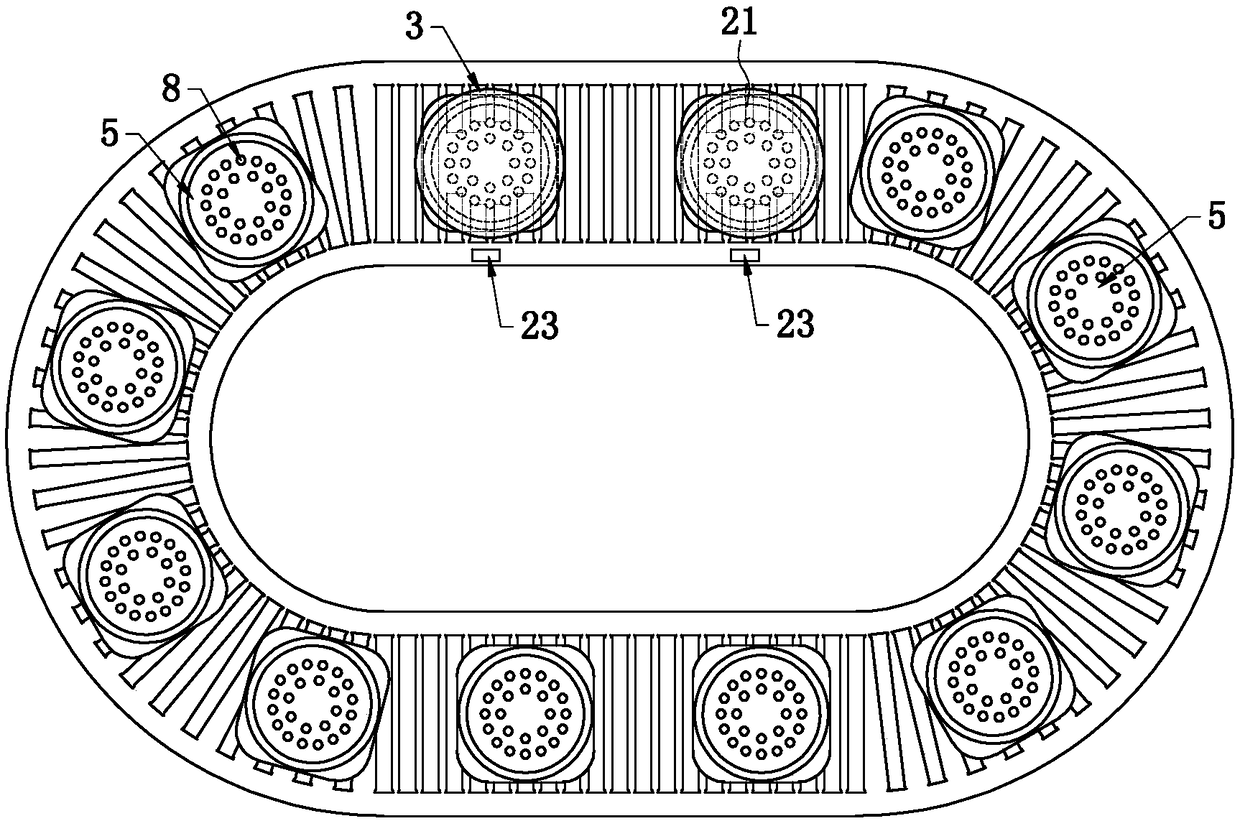

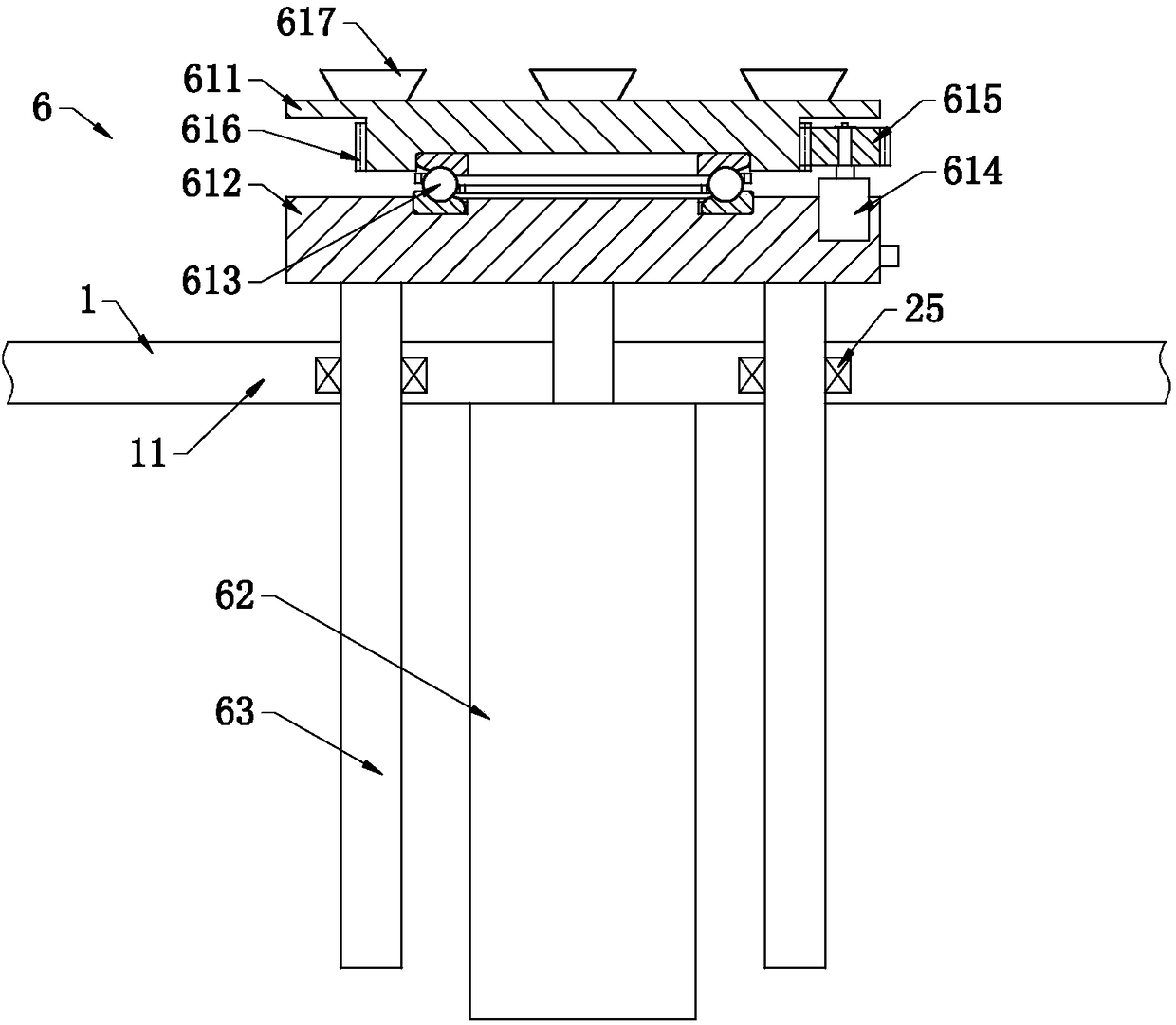

[0040] Such asfigure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Commonly shown, an environment-friendly automatic painting equipment includes a frame 1, a spray booth 3 and a drying chamber 2 installed on the frame 1, and also includes two automatic lifting and turning units 6. The paint spraying room 3 is located on the upper side of the drying room 2 and communicates with the drying room 2; the top of the drying room 2 is provided with a material inlet and outlet 21, and the material inlet and outlet 21 is located on the side of the paint spraying room 3; two automatic lifting and rotating Units 6 are respectively located below the paint spray booth 3 and below the material inlet and outlet 21 . The drying chamber 2 is provided with several transmission rollers 4 arranged at intervals, and several transmission rollers 4 are arranged in a ring; the transmission rollers 4 are provided with 12 trays 5 for installing workpieces 8; the transmission rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com