Die casting surface treatment process

A surface treatment and die-casting technology, which is applied in the field of die-casting surface treatment technology, can solve the problems of reducing yield, increasing production cost, and gas cannot be discharged in time, so as to reduce bulging and improve product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

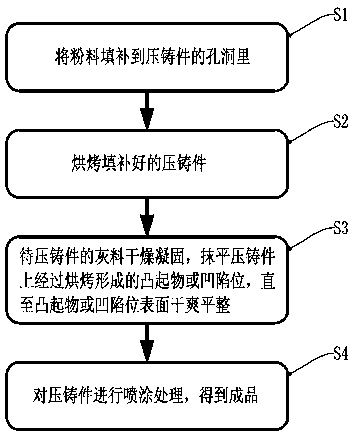

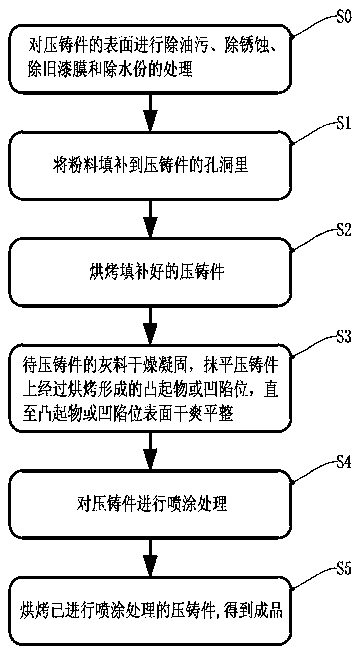

Embodiment 1

[0051] S1, filling the ashes into the holes of the die casting;

[0052] S2. Adjust the temperature of the oven to 100°C, and bake the filled die casting;

[0053] S3. After the ashes of the die-casting parts are dried and solidified, smooth out the protrusions or depressions formed on the die-casting parts after baking until the surface of the protrusions or depressions is dry and smooth;

[0054] S4. Spraying the die casting to obtain a finished product.

Embodiment 2

[0056] S1, filling the ashes into the holes of the die casting;

[0057] S2. Adjust the temperature of the oven to 200°C, and bake the filled die-casting;

[0058] S3. After the ashes of the die-casting parts are dried and solidified, smooth out the protrusions or depressions formed on the die-casting parts after baking until the surface of the protrusions or depressions is dry and smooth;

[0059] S4. Spraying the die casting to obtain a finished product.

Embodiment 3

[0061] S1, filling the ashes into the holes of the die casting;

[0062] S2. Adjust the temperature of the oven to 400°C, and bake the filled die casting;

[0063] S3. After the ashes of the die-casting parts are dried and solidified, smooth out the protrusions or depressions formed on the die-casting parts after baking until the surface of the protrusions or depressions is dry and smooth;

[0064] S4. Spraying the die casting to obtain a finished product.

[0065]Observing the surface of the finished product obtained according to the above process with the naked eye, the analysis in the following table is obtained.

[0066] Table 1 Surface roughness

[0067] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com