Precision plastic welding equipment

A technology of plastic welding and equipment, applied in the field of precision plastic welding equipment, can solve the problems of insufficient heating depth, poor product quality, too deep heating, etc., to improve transmission accuracy, avoid excessive heating or insufficient heating depth, and high motion accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

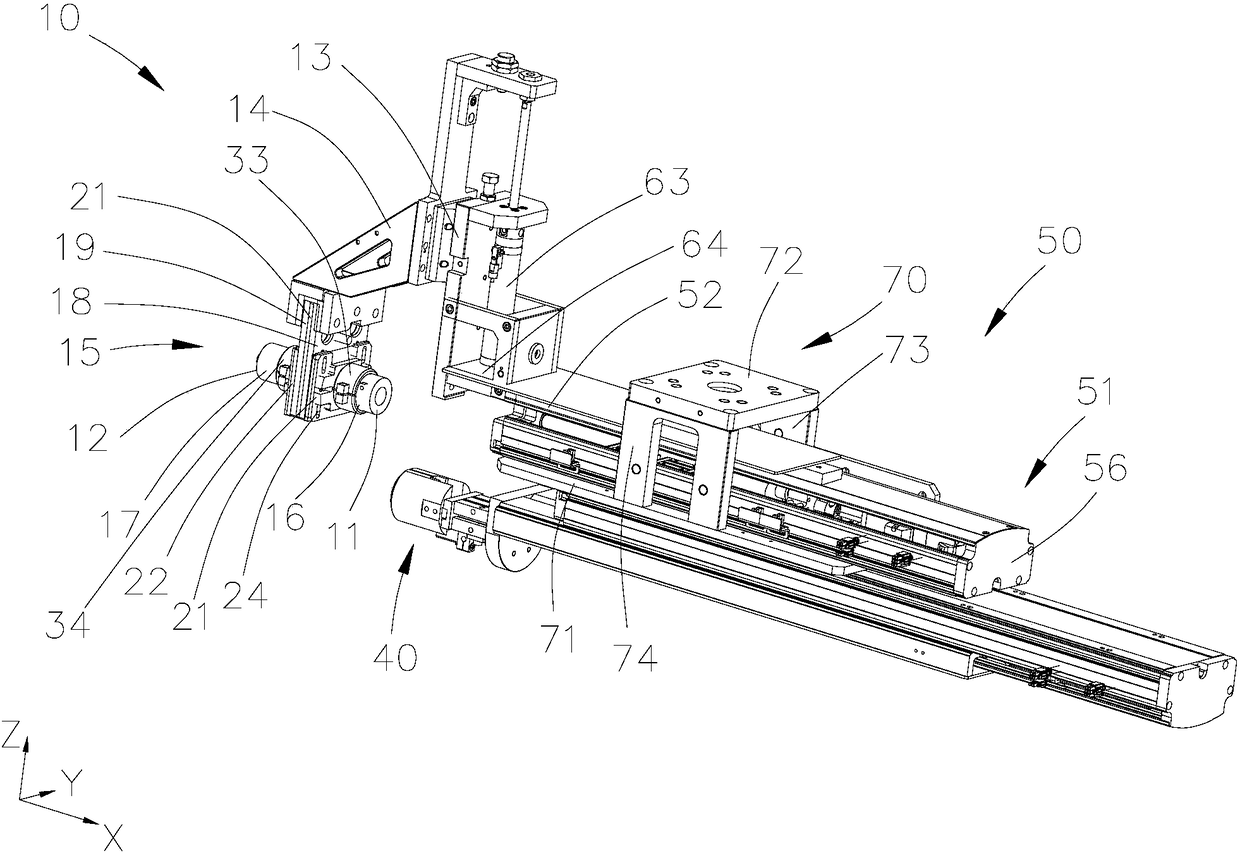

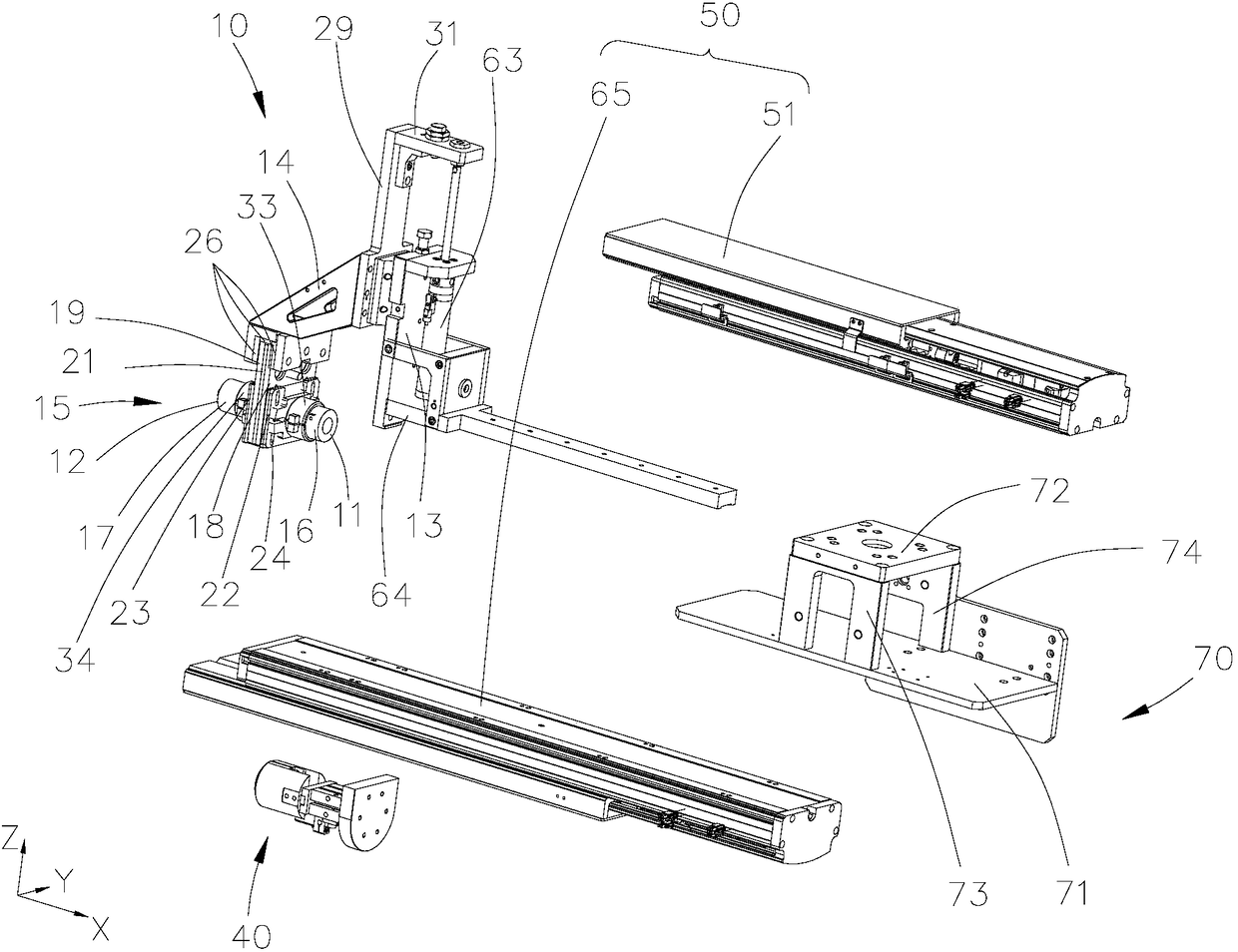

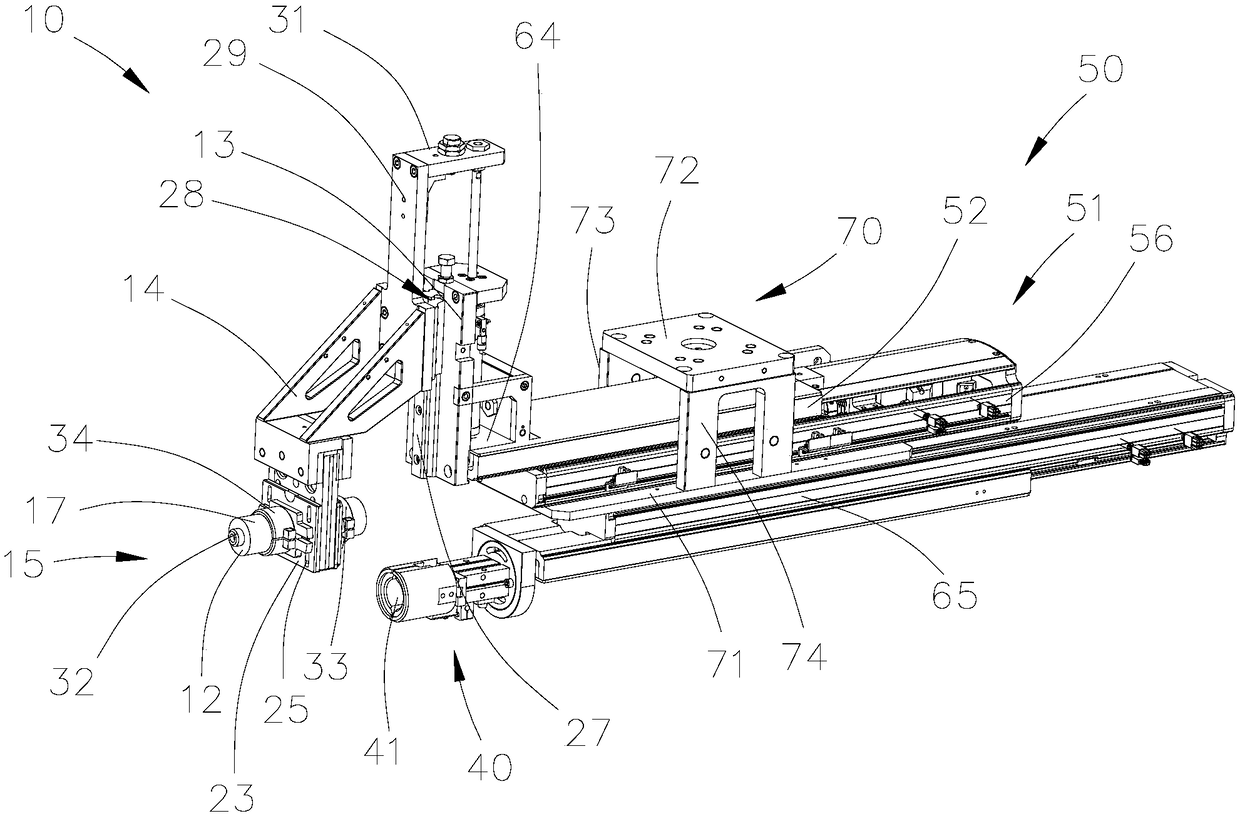

[0037] see Figure 1 to Figure 7 ,Such as Figure 1 to Figure 7, an embodiment of the present invention provides a precision plastic welding equipment for welding a first plastic part (not shown in the figure) to a second plastic part (not shown in the figure), the first plastic part includes a welding part (in the figure not shown), the second plastic part includes a mounting part (not shown) welded and installed with the welding part, including a hot-melt device 10, a conveying device 40, a driving device 50 and a fixing bracket 70, and the hot-melt device 10 has a first hot-melt end 11 in contact with the first plastic part and a second hot-melt end 12 in contact with the second plastic part, wherein the first hot-melt end 11 is in contact with the welding part And it is used to heat-melt the welding part, the second hot-melt end 12 is in contact with the mounting part of the second plastic part and is used to heat-melt the mounting part; the conveying device 40 is used to...

Embodiment 2

[0061] The precision plastic welding equipment provided by the embodiments of the present invention includes the precision plastic welding equipment provided by the above embodiments, which have the same partial structure and function, and will not be repeated here. The difference between the precision plastic welding equipment of this embodiment and the precision plastic welding equipment of Embodiment 1 is that the welding assembly 15 of this embodiment includes a built-in first welding head 16 and is used for heating and detecting the temperature of the first welding head 16 The first heating rod (not shown) and the second heating rod (not shown) built in the second welding head 17 and used for heating and detecting the temperature of the second welding head 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com