Buoyancy platform driving device for sewage treatment floating cover system

A technology for sewage treatment and buoyancy platform, applied in water/sewage treatment, water/sludge/sewage treatment, transportation and packaging, etc., can solve the problem of reducing the welding accuracy of two adjacent rolls of HDPE anti-seepage membrane and adjusting the HDPE anti-seepage membrane. Inaccurate, heavy weight of the anti-seepage membrane, etc., to improve the laying efficiency, reduce the labor intensity, and ensure the normal movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

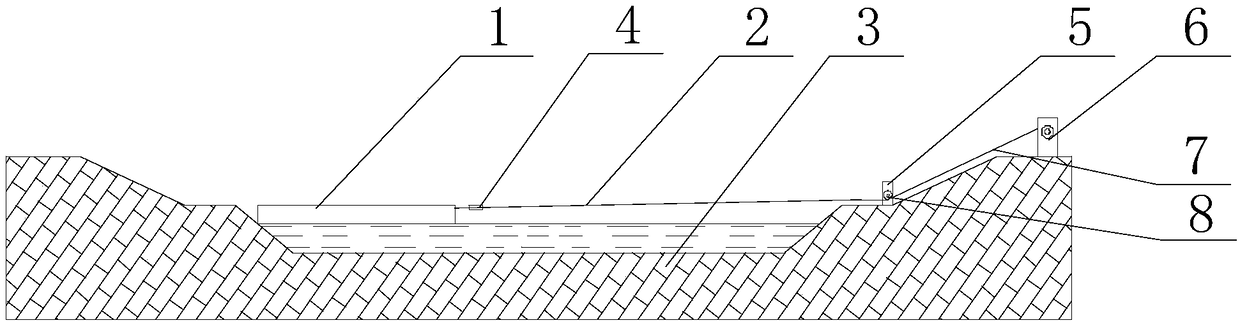

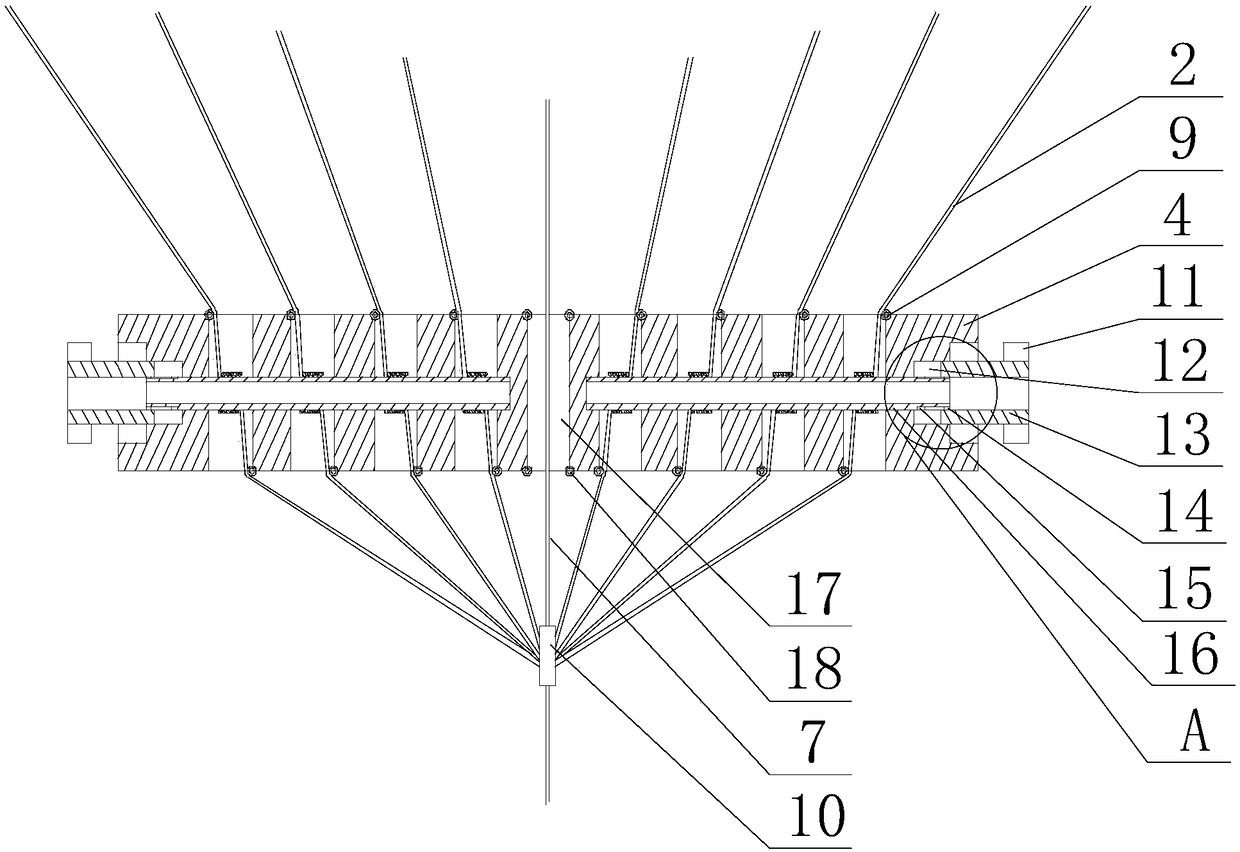

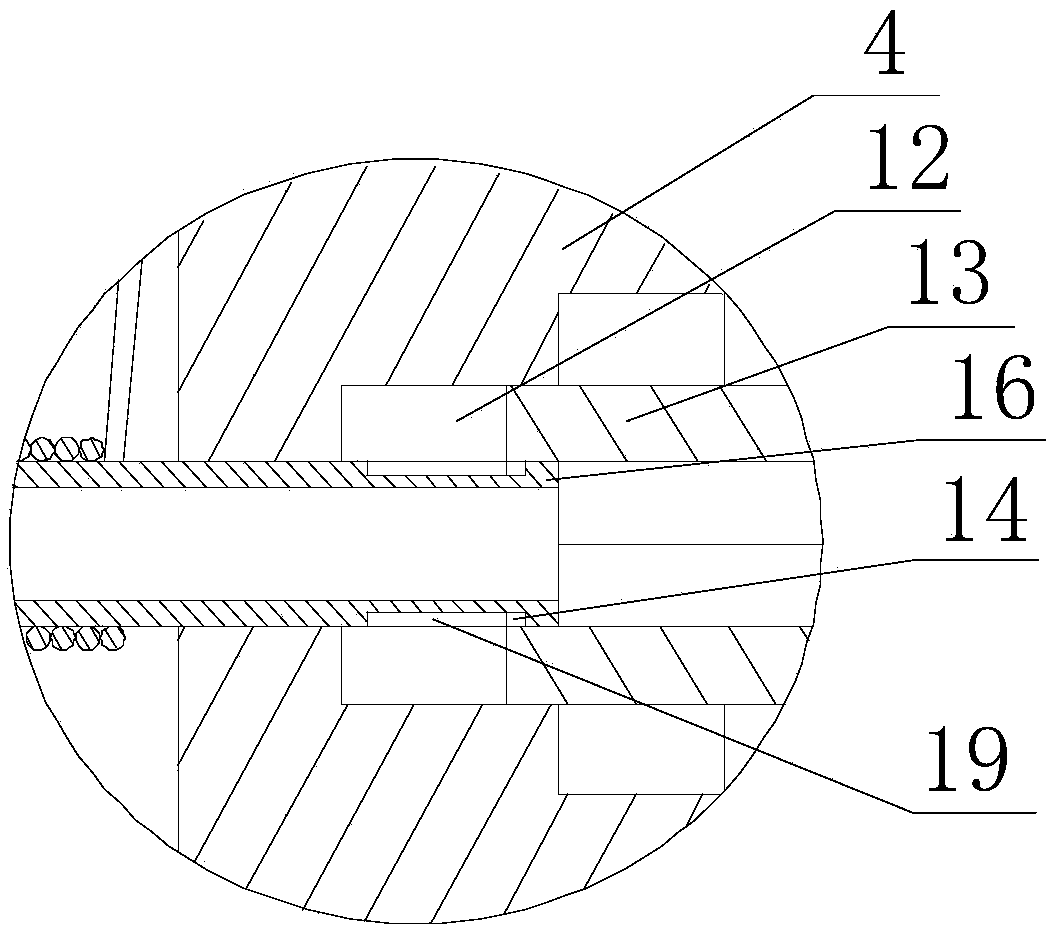

[0029] Such as Figure 1~5 As shown, the present embodiment includes a hoist 6, a traction rope, a rectangular traction block 4 and a steering column 5, on which the steering column 5 is provided with a redirection mechanism 8, and the traction rope is connected with the hoist after bypassing the redirection mechanism 8. 6 is connected to the output end of the traction block 4. There are a plurality of wire passing holes with axes parallel to each other on the traction block 4. Limiting grooves 12 are opened at both ends of the traction block 4, and the axes of the limiting grooves 12 are in line with the passing The axis of the line hole is vertical, and a rotating shaft 16 is arranged on the groove wall of each limiting groove 12, and the end of the rotating shaft 16 moves sequentially through the limiting groove 12 and a plurality of The wire hole also includes a clamp 10 connected with the traction rope, a limit cylinder 13 matched with the limit groove 12, and a plurality...

Embodiment 2

[0035] Such as Figure 1~5 As shown, in this embodiment, a through hole 17 with an axis parallel to the wire passing hole is opened in the middle of the traction block 4 , and the main pull rope 7 is connected to the clamp 10 after moving through the small hole. Further, a through hole 17 is set in the middle part of the traction block 4 to facilitate the passing of the main stay rope 7, and one end of the main stay rope 7 is connected with the middle part of the buoyancy platform 1, and the other end is connected with the clamp 10. Driven by the drive, the length of the main stay rope 7 remains unchanged, that is, when adjusting, the buoyancy platform 1 will take the main stay rope 7 as the center, and the forward and reverse rotation of the two rotating shafts 16 will make them respectively located on both sides of the buoyancy platform 1. The lengths of the side stay ropes 2 are different, and the increase and decrease of the lengths of the side stay ropes 2 on the same sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com