Prefabricated integral assembled type track for shield tunnel and construction method

A technology of shield tunnel and construction method, applied in the field of rail transit, can solve the problems of limited adaptability, difficult lateral and vertical positioning of the track slab, and no assembly construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

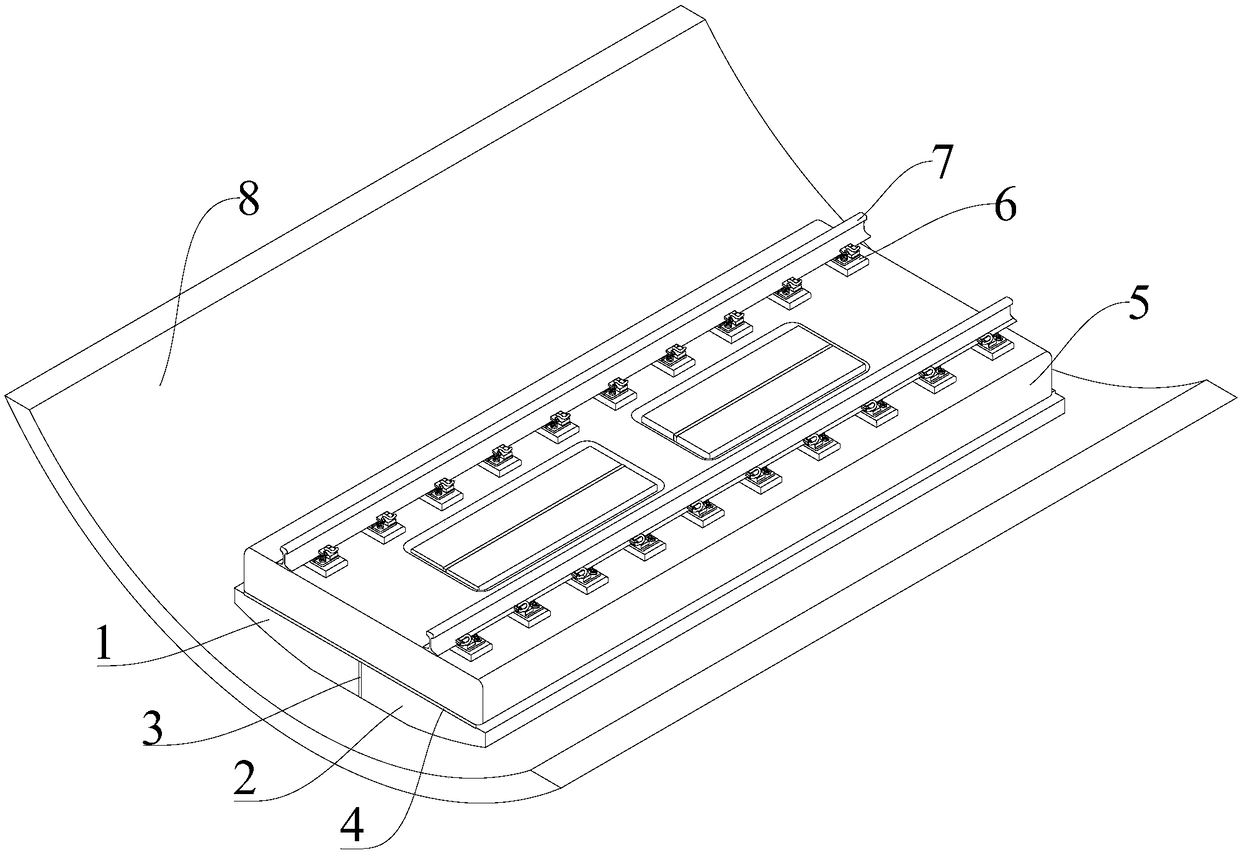

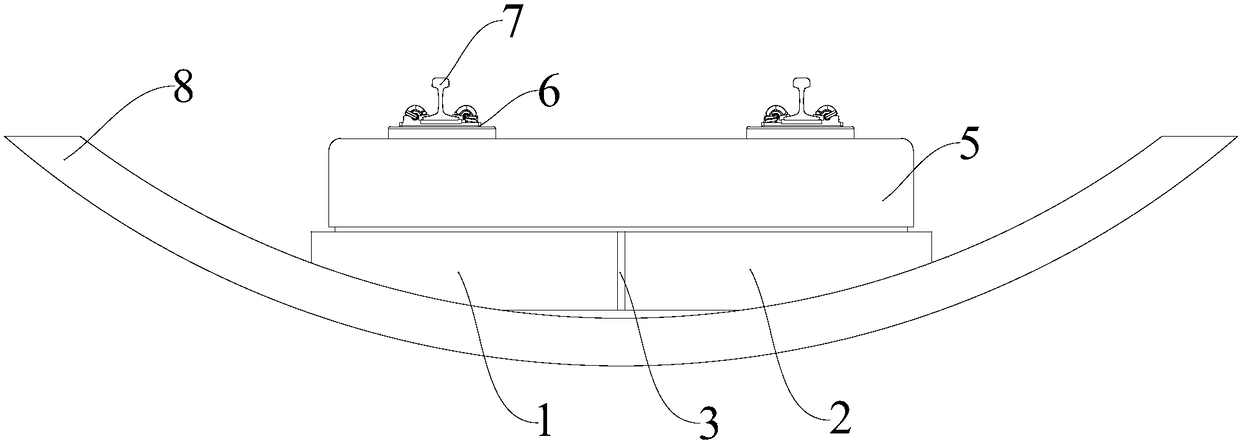

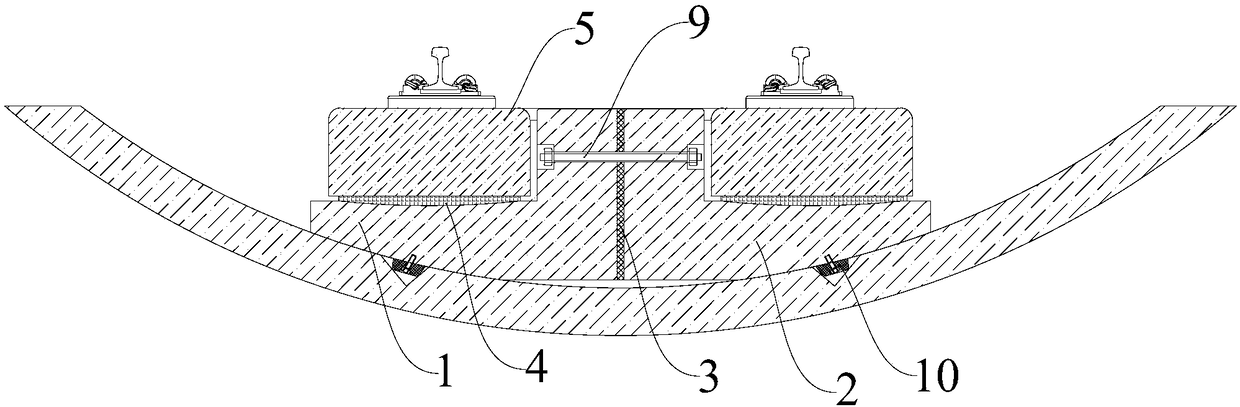

[0040] Such as Figure 1-Figure 3 As shown, a shield tunnel prefabricated integrally assembled track includes a track system and a foundation system, both of which are prefabricated and assembled, wherein the track system includes steel rails 7, fasteners 6 and frame-type The track plate 5, the basic system includes a left base 1, a right base 2, an intermediate adjustment pad 3 and a buffer damping pad 4.

[0041] The left base 1 and the right base 2 are arranged on the tunnel segment 8, and a positioning block 10 is arranged under the left base 1 and the right base 2, and the positioning block 10 is connected with the tunnel segment 8. The bolt hand holes are adapted to realize the positioning of the left and right bases.

[0042] A middle adjustment pad 3 is arranged between the left base 1 and the right base 2 , and the left base 1 , the right base 2 and the middle adjustment pad 3 are also connected by a screw 9 .

[0043] The frame-type track plate 5 is arranged on the...

Embodiment 2

[0047] A construction method for a shield tunnel prefabricated integrally assembled track, comprising any one of the shield tunnel prefabricated integrally assembled tracks, the construction method being:

[0048] Step 1: Prefabricate the left base 1, the right base 2 and the frame type track plate 5 in the factory, and transport the left base 1, the right base 2 and the frame type track plate 5 to the construction site;

[0049] Step 2: Construct the track engineering measurement plane and the elevation control network, and carry out the construction lofting of the left base 1, the right base 2 and the frame type track slab 5;

[0050] Step 3: Transport the left base 1 and the right base 2 to the designated positions, and set an intermediate adjustment pad 3 between them to realize the adjustment of the positions of the left and right bases. The left base 1 and the right base 2 and the middle adjustment pad 3 are also connected by fasteners;

[0051] Step 4: The positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com