A flywheel battery with double flywheel structure

A technology of flywheel batteries and double flywheels, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the radial length of flywheel batteries, large axial space, and difficulty in reducing the volume of flywheel batteries, so as to reduce imbalance Effects of disturbance, increased energy storage, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

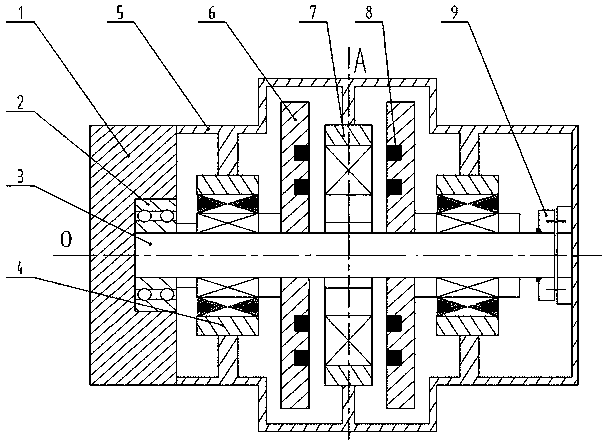

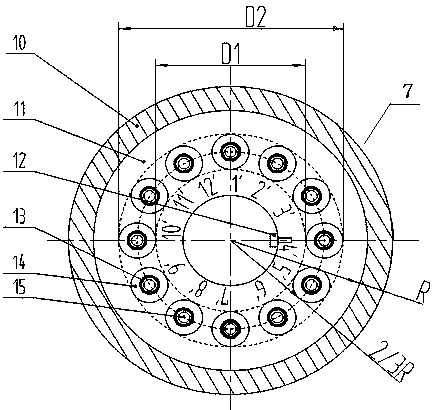

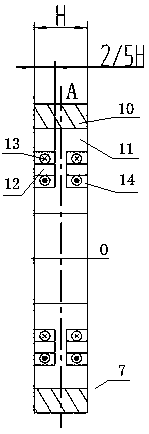

[0017] Such as figure 1 As shown, the outermost part of the present invention is an outer shell 5 and an end cap 1, and one axial end of the outer shell 5 is sealed and connected with the end cap 1, and a vacuum chamber is surrounded by the outer shell 5 and the end cap 1. In the middle of the inside of the vacuum chamber is the rotating shaft 3. The rotating shaft 3 has a common central axis with the outer shell 5 and the end cover 1. The central axis O of the rotating shaft 3 is also the outer shell 5, the end cover 1 and the central axis, that is, the entire flywheel battery of the central axis. The outer casing 5 is a rotationally symmetrical structure, the axis of rotational symmetry is the central axis O, the axial left and right symmetrical axis in the middle of the axial direction of the rotating shaft 3 is A, and the axial left and right symmetrical axis A and the central axis O intersect perpendicularly on the same radial section .

[0018] Inside the vacuum chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com