Hot fill process with closures made from bimodal polyethylene compositions

A bimodal polyethylene, sealing lid technology, applied in packaging and other directions, can solve the problem of not showing the final polymer form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

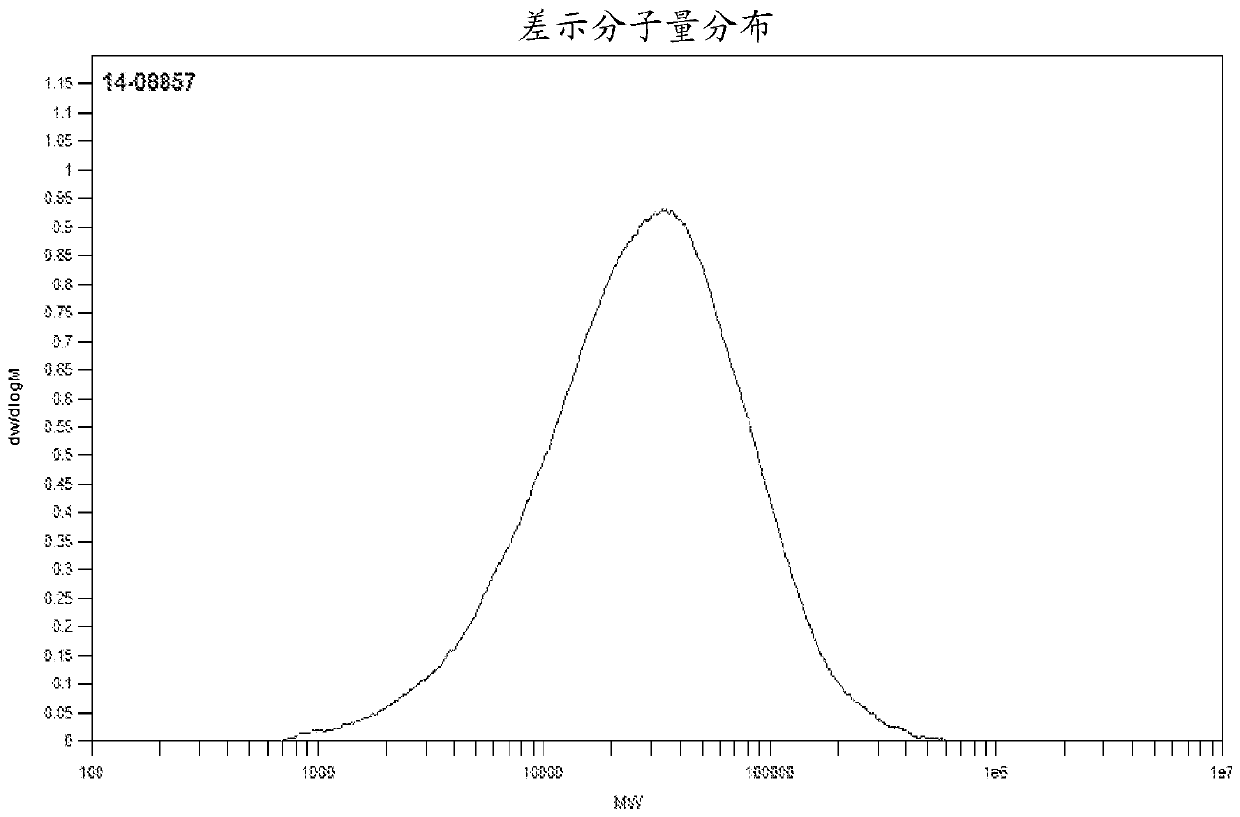

[0317] Example 1 (comparative) is made by having a melt index I of 32 g / 10min 2 , 0.951 g / cm 3 The density and the weight average molecular weight Mw / Mn of 2.88 and the sealing cap made of unimodal polyethylene resin made using Ziegler Natta catalyst in the solution olefin polymerization method. This resin is available as a SCLAIR ® 2712 was purchased from NOVA Chemicals Corporation. The GPC curve of this resin is listed in Figure 1A middle.

Embodiment 2

[0318] Example 2 is a sealing cap made of a bimodal polyethylene composition and having a melt index I of 1.5 g / 10 min 2 , 0.953 g / cm 3 Density and weight average molecular weight Mw / Mn of 8.47. The bimodal polyethylene composition used in Example 2 was made using a single site catalyst in a solution olefin polymerization process. Further details regarding the bimodal polyethylene composition used in Example 2 and its method of preparation are disclosed in US Patent 8,962,755, which is hereby incorporated by reference in its entirety. The GPC curve of this resin is listed in Figure 1B middle.

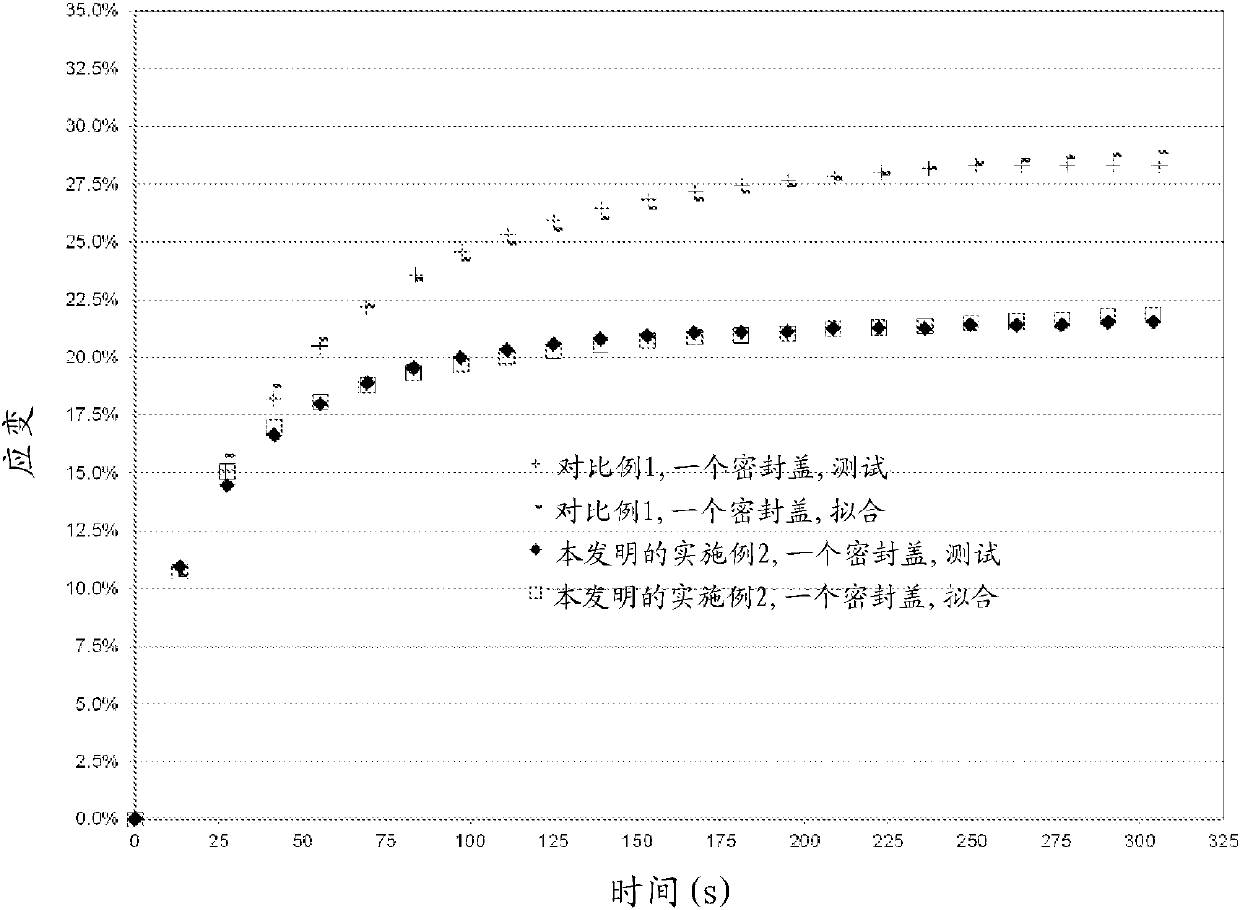

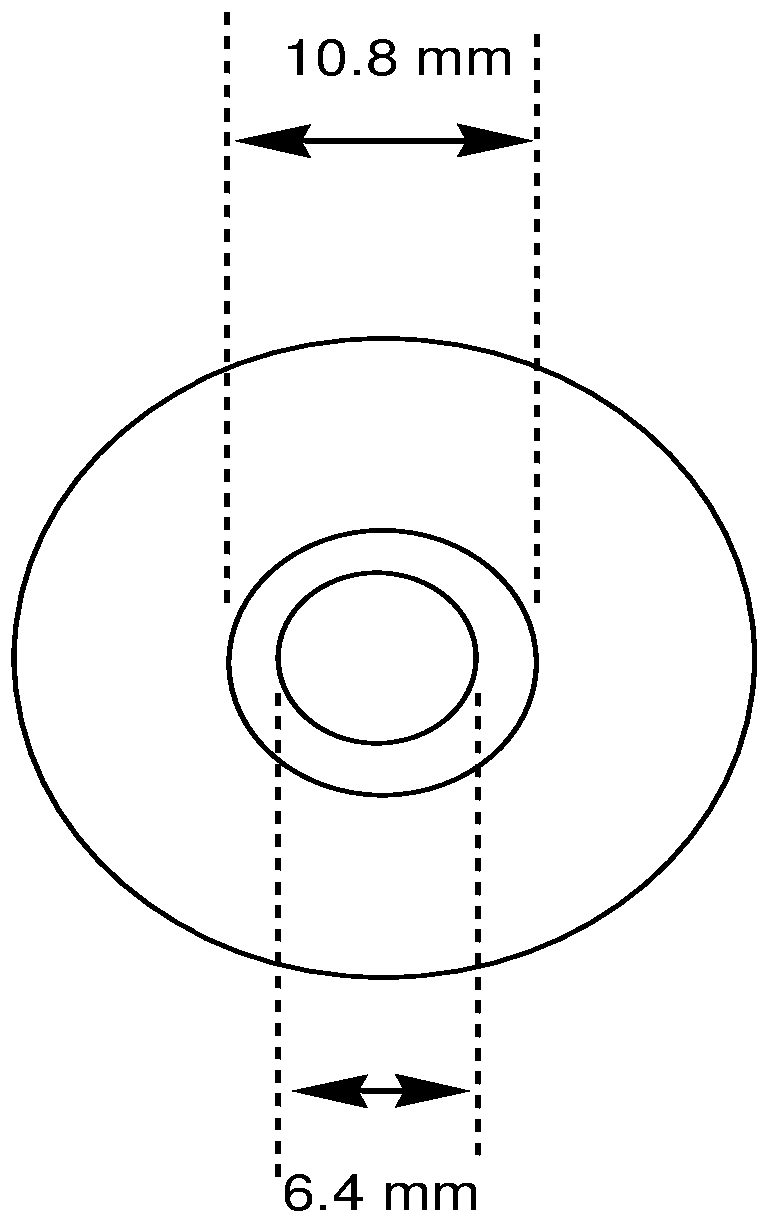

[0319] The polymers used to make the sealing caps in Examples 1 and 2 are shown in Table 1A along with their panel data. Data for the first and second ethylene copolymer components of Example 2 are shown in Table 1B. The sealing caps were formed by injection molding, and the injection molding processing conditions are listed in Table 2. Seal cap dimensions are provided in Table 3...

Embodiment approach A

[0391] Embodiment A. A method of filling a container, the method comprising: adding hot liquid to the container through a container opening, sealing the container opening with a sealing cap comprising a bimodal polyethylene composition, and allowing the hot liquid to communicate with the container. contact with the inner surface of the sealing cap; wherein the bimodal polyethylene composition comprises:

[0392] (1) 10 to 70% by weight of a first ethylene copolymer having a melt index I of less than 0.4 g / 10min 2 ; Molecular weight distribution M less than 2.7 w / M n ; and 0.920 to 0.955 g / cm 3 density; and

[0393] (2) 90 to 30% by weight of a second ethylene copolymer having a melt index I of 100 to 20,000 g / 10min 2 ; Molecular weight distribution M less than 2.7 w / M n and a density greater than but less than 0.967 g / cm of the first ethylene copolymer 3 density of;

[0394] wherein the density of the second ethylene copolymer is less than 0.037 g / cm higher than the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com