Segment rolling bearing and disk brake device

A rolling bearing and segmented technology, which is applied to rolling contact bearings, rotating bearings, bearings, etc., can solve the problem of insufficient accuracy and achieve accurate and simple positioning and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

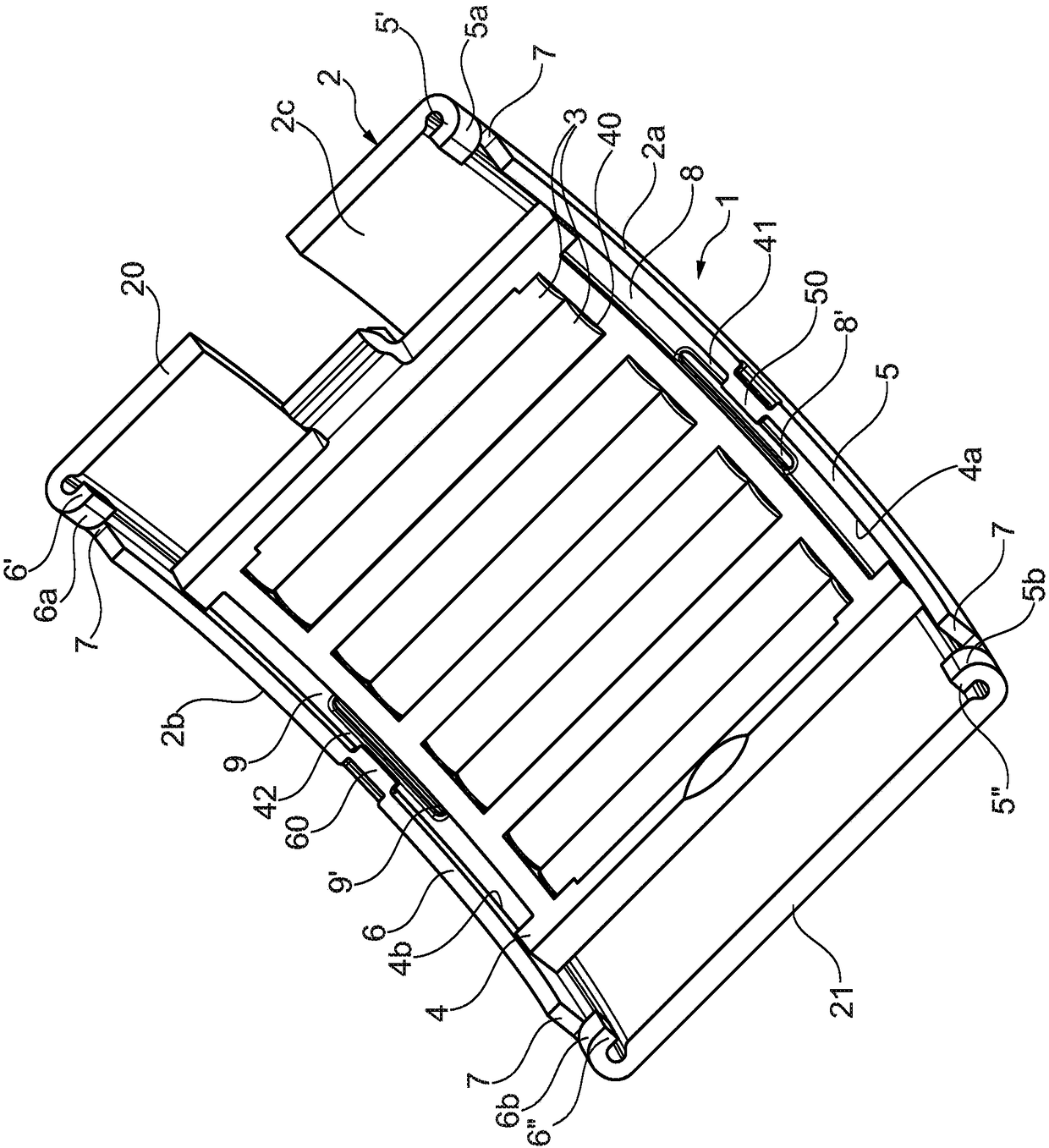

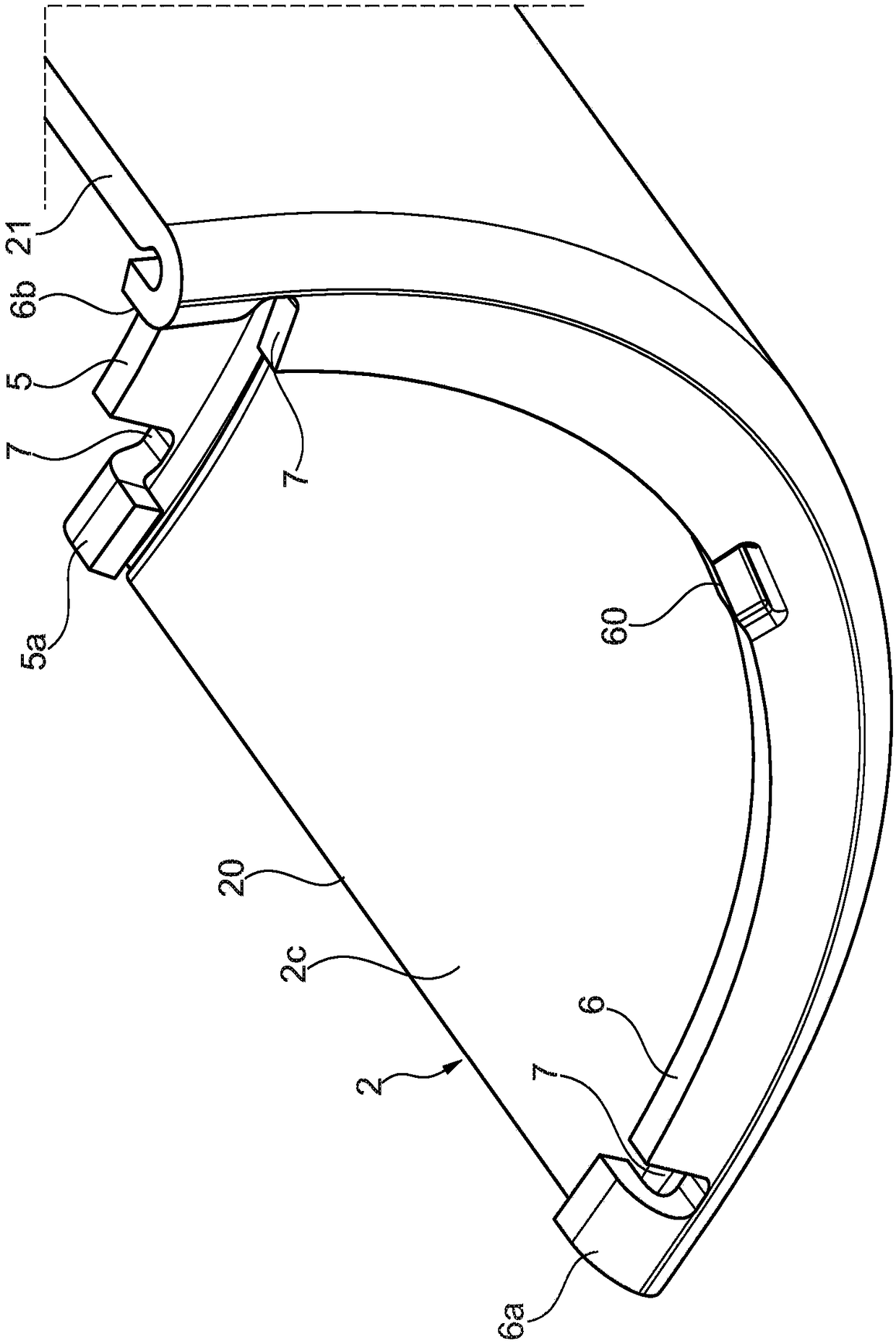

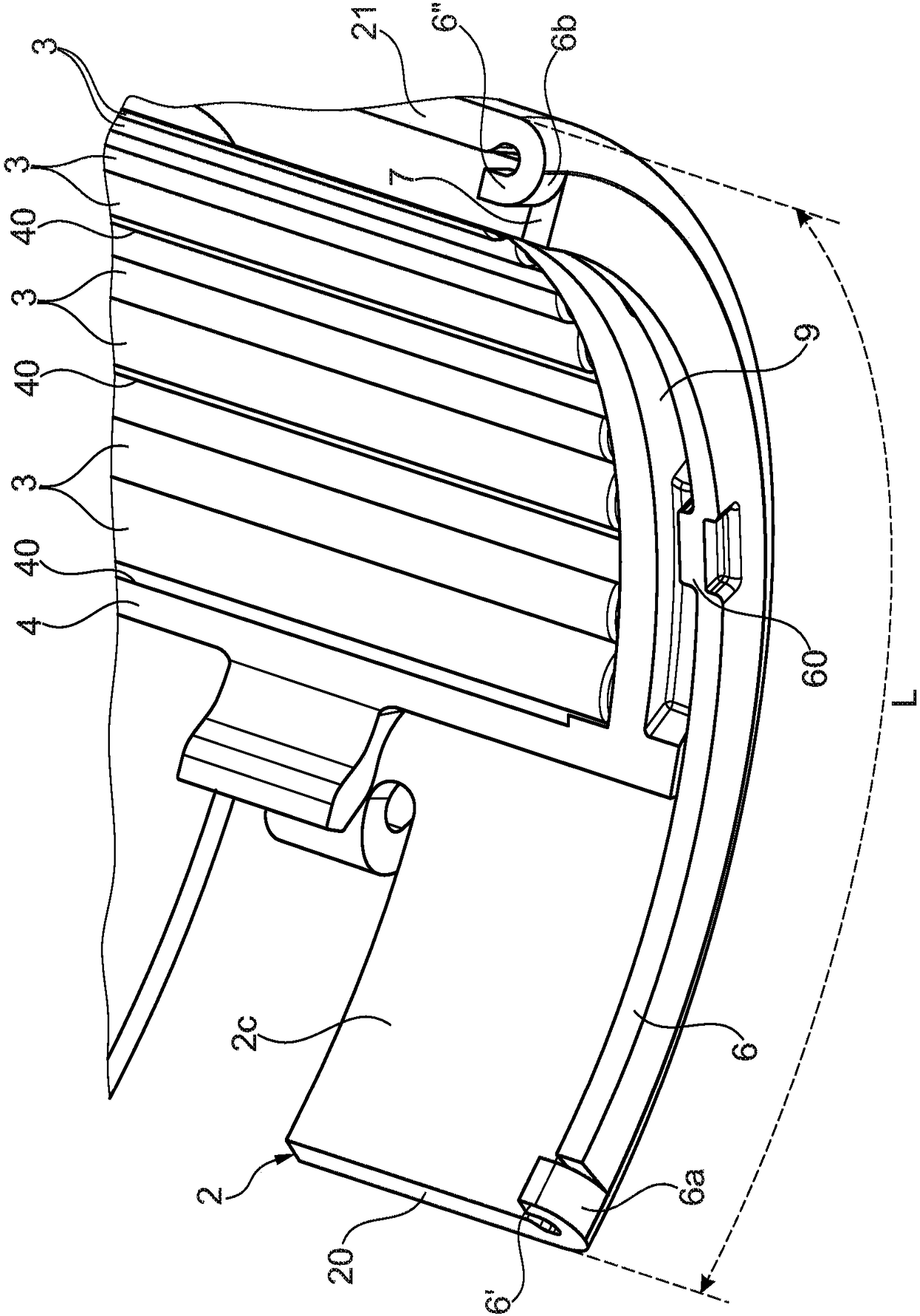

[0029] figure 1 Shows a three-dimensional view of a segmented rolling bearing 1 comprising a bearing housing 2 with a curved raceway 2c for the rolling elements 3 and a segmented cage 4 comprising several rolling elements Body 3. The bearing sleeve 2 has on its two longitudinal sides 2 a , 2 b respectively guide webs 5 , 6 for laterally guiding the segmented cage 4 , wherein each guide web 5 , 6 is substantially perpendicular to the bearing sleeve The raceway 2c of 2 is oriented. Each guide tab 5, 6 has a cutout 7 at each of its two ends 5', 5"; 6', 6", perpendicular to the longitudinal sides 2a, 2b of the bearing sleeve 2 In such a way that guide web sections 5 a , 5 b ; 6 a , 6 b are formed on both ends 20 , 21 of bearing sleeve 2 on both sides. The guide web sections 5 a , 5 b ; 6 a , 6 b are bent in the direction of the raceway 2 c and form end stops for the segmented cage 4 . The overall length L of the bearing sleeve 2 (compared to image 3 ) extends between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com