Synchronization Performance Evaluation Method of Synchronizer Ring

A technology of synchronizer rings and synchronization performance, which is applied in the testing of machines/structural components, instruments, clutches, etc., and can solve problems such as gear noise and slow synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

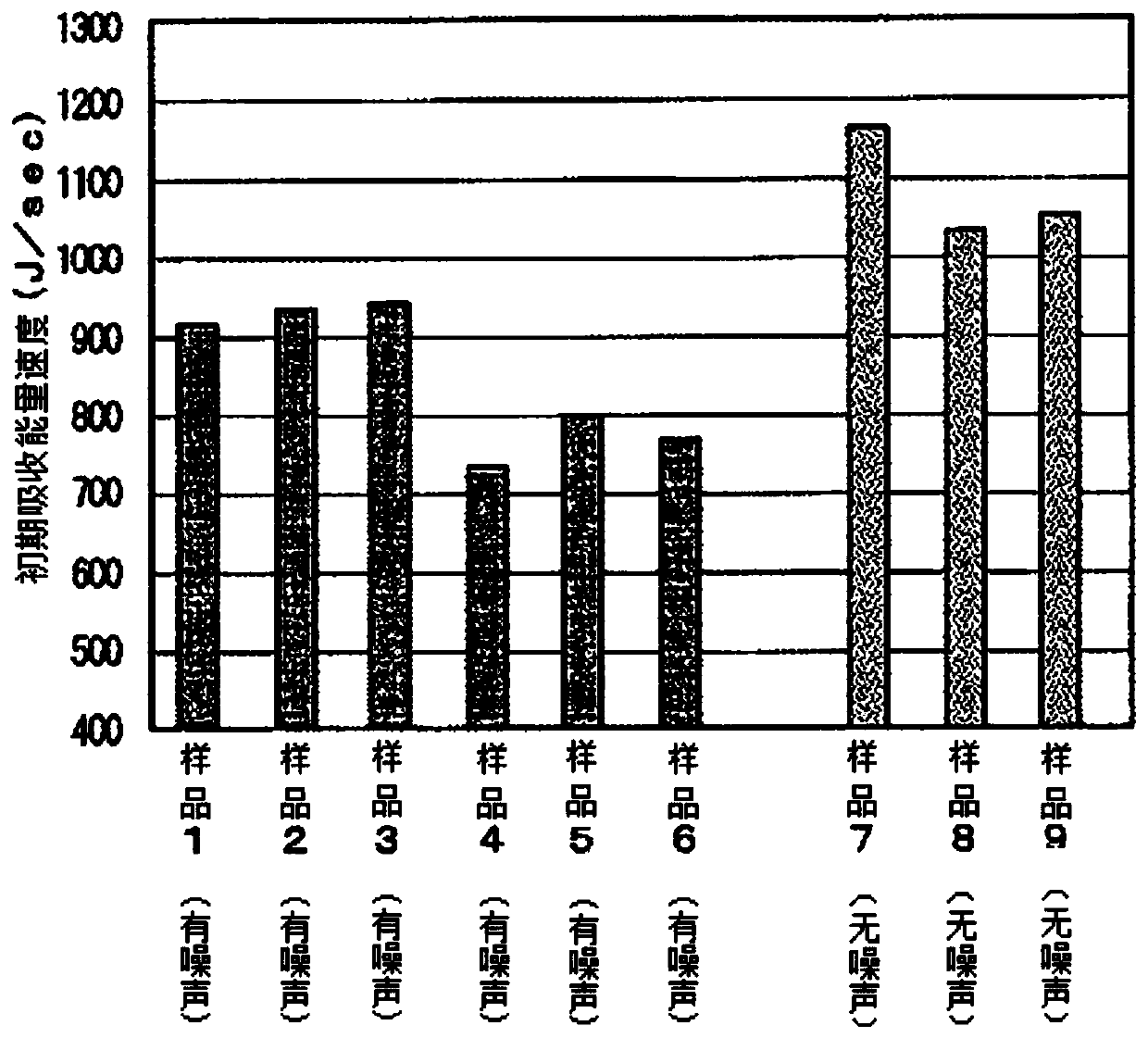

[0029] In Japanese Patent Application No. 2015-006116 (invention name: method for manufacturing friction material of sliding parts and friction material thereof), the inventors of the present invention proposed a friction material with high porosity.

[0030] The friction material has a high porosity, can keep gear oil on the surface, and has good heat transfer performance, and the synchronization speed between the synchronizer ring and the gear is fast. It is used in the 16-speed transmission used on the above-mentioned large trucks. In the case of the synchronizer ring of the auxiliary transmission, it can be used as the best friction material.

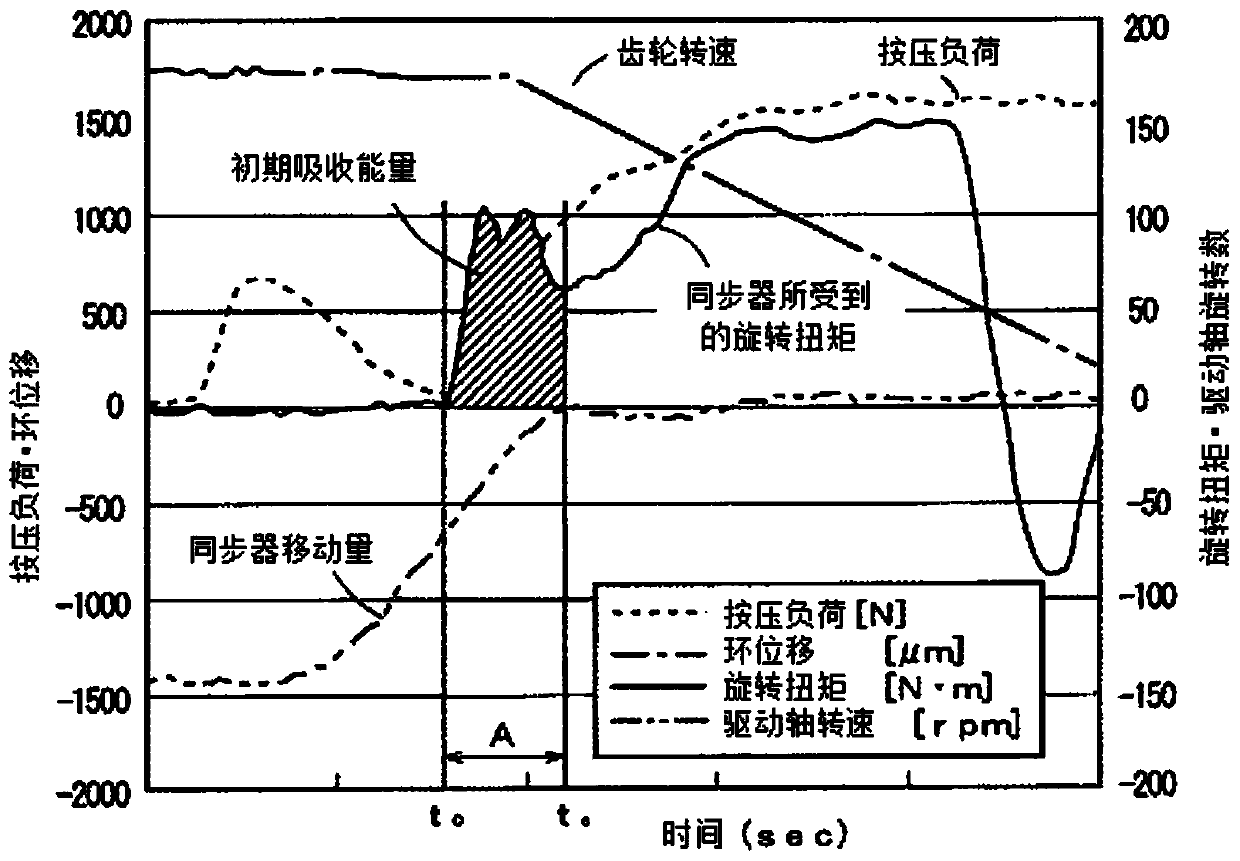

[0031] Therefore, the inventors of the present invention focused on the gear oil formed on the surface of the friction material of the synchronizer ring for the reason why the synchronous speed increases when a friction material with a high porosity is used, and considered that the synchronous speed is affected by the gear oil formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com