Fast and efficient garlic clove separating device

A technology for garlic and clove separation, which is applied in the field of garlic clove separation equipment, and can solve problems such as crushing, increasing processing costs, and unfavorable follow-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

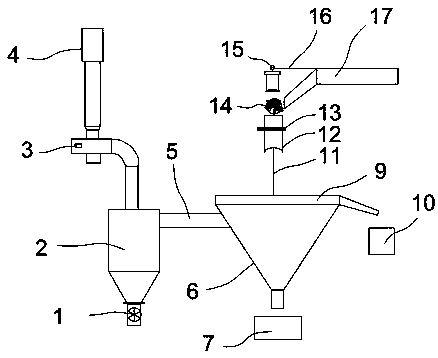

[0019] like Figure 1-5 As shown, the fast and efficient garlic splitting equipment includes a cone bucket 6, a garlic clove collection box 7 is arranged below the cone bucket 6, a vibrating screening machine 9 is arranged at the upper end of the cone bucket 6, and a garlic splitting mechanism is installed above the vibrating screening machine 9, A feed inlet 17 is provided above the garlic splitting mechanism, one side of the cone bucket 6 is connected to the separator 2 through a pipeline 5, the other side of the cone bucket 6 is provided with a garlic recovery box 10, and the upper end of the separator 2 is connected to the exhaust pipe 3, and the exhaust The upper part of the tube 3 is equipped with a connecting exhaust fan 4, and the lower end of the separator 2 is equipped with a vibrating discharger 1. By setting up a vibrating screening machine, the divided garlic is screened, and the unqualified ones enter the garlic recycling box to be divided again. The qualified ga...

Embodiment 2

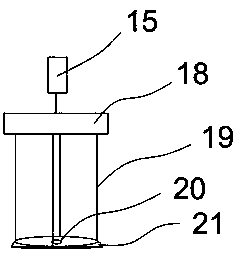

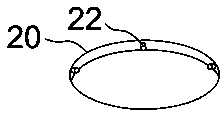

[0026] The working principle of the fast and efficient garlic splitting device of the present invention is to drop the garlic 14 from the feed port 17 into the cylinder 12, and after the separation sensor 22 senses the garlic falling, the feedback information is given to the motor 15, and the motor 15 starts to drive The telescoping device 18 rotates, and the telescoping rod 19 on the telescoping device 18 is extended downward, so that the turntable 21 rotates and presses down the garlic, and the bottom of the garlic 14 is continuously deepened through the tip of the separation needle 11. Under the action of the triangular separation piece 23, The separation of the garlic cloves is accelerated, and the separated garlic 14 is screened by the vibration screening machine 9, so that the unqualified garlic 14 falls into the garlic recovery box 10, and the qualified garlic 14 falls into the garlic clove collection box 7 through the cone bucket 6 , the garlic skin is then separated fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com