Coffee machine and operating method thereof

A coffee machine and coffee technology, applied in coffee mills, beverage preparation devices, household appliances, etc., can solve the problems of coffee powder adhesion and inability to seal, and achieve the effect of preventing moisture adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

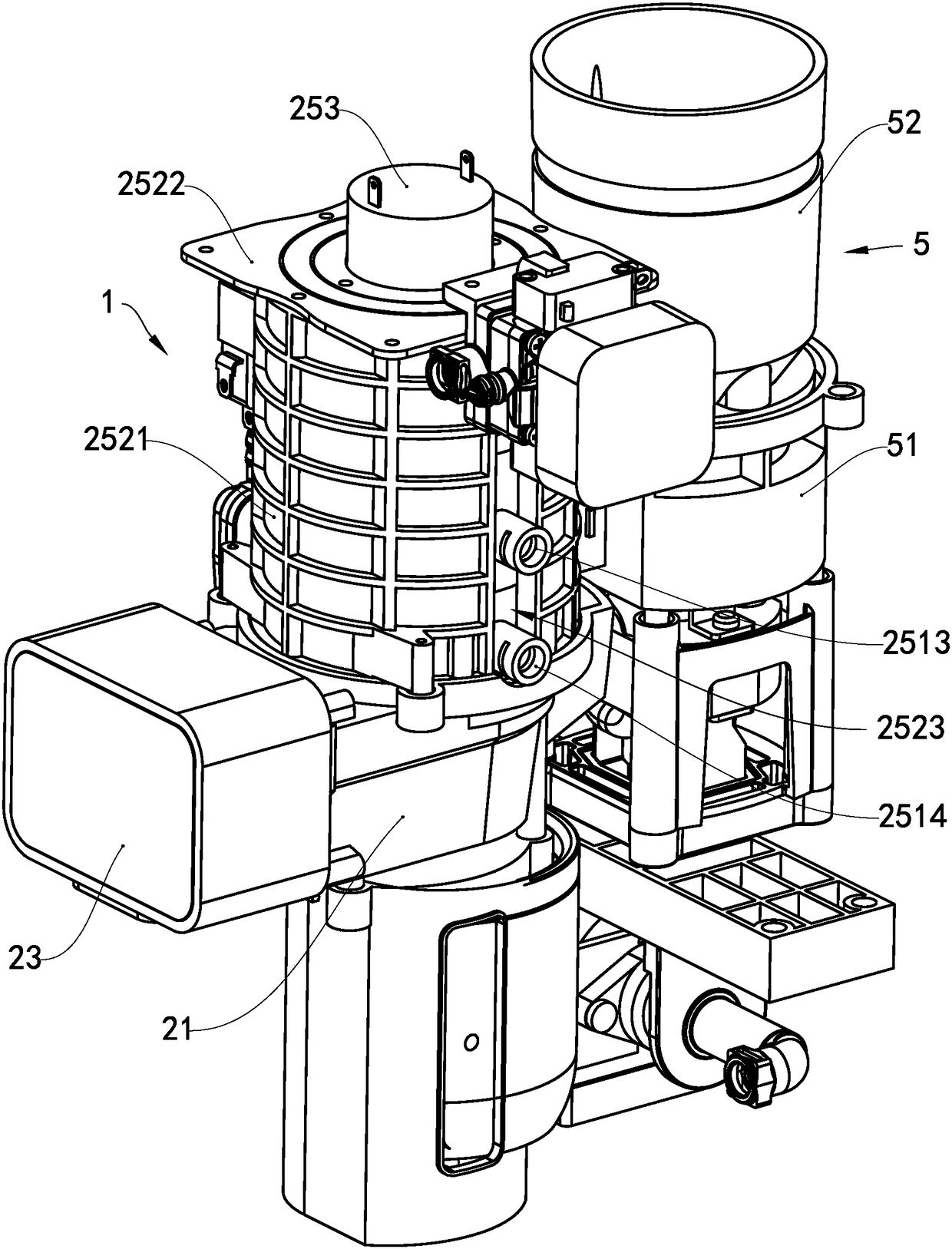

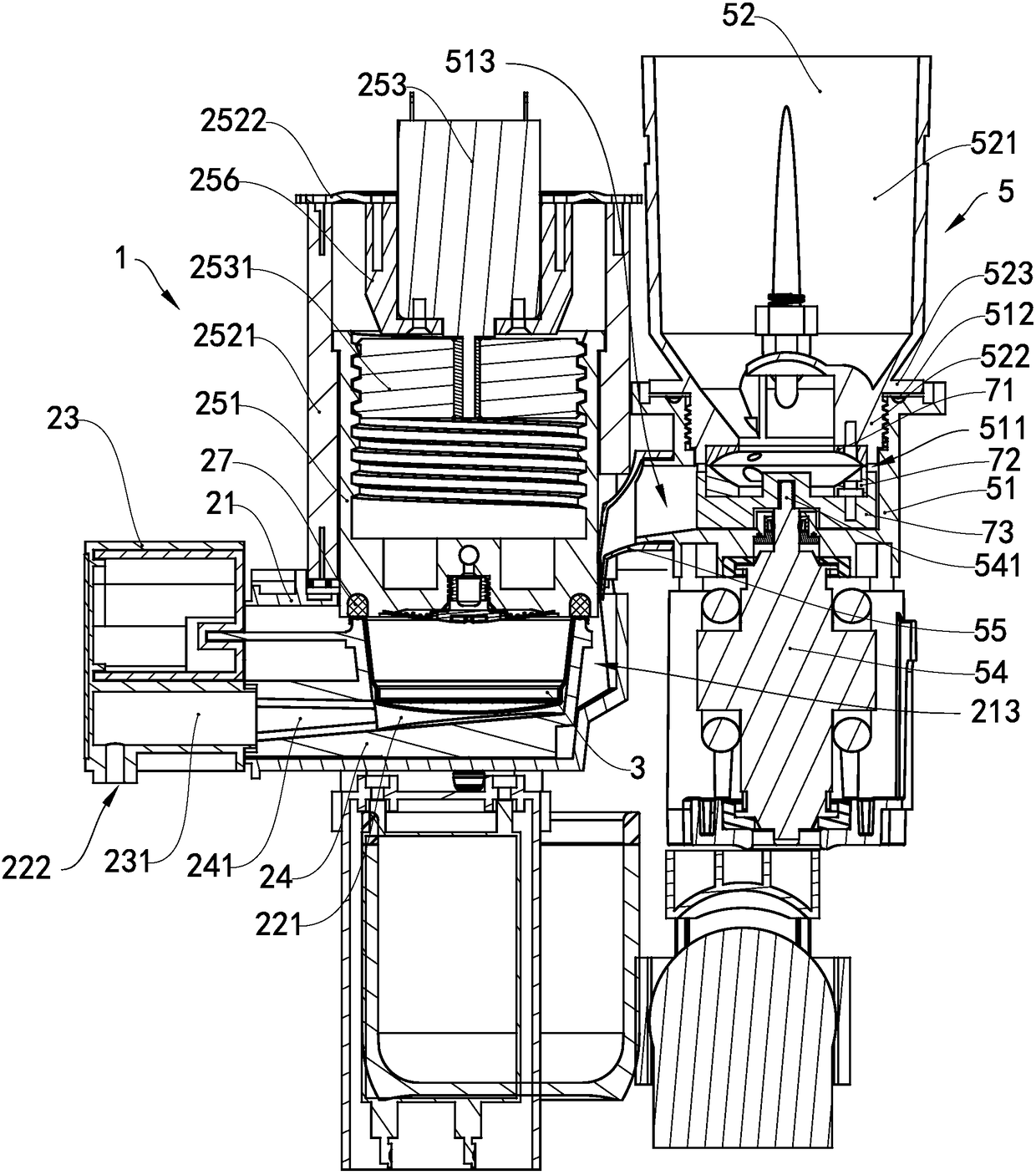

[0038] see figure 1 , the coffee machine of this embodiment includes a brewing unit 1 and a bean grinding unit 5, the bean grinding unit 5 is used to grind coffee beans into coffee powder, and the brewing unit 1 is used to brew the coffee powder made by the bean grinding unit 5 into coffee liquid.

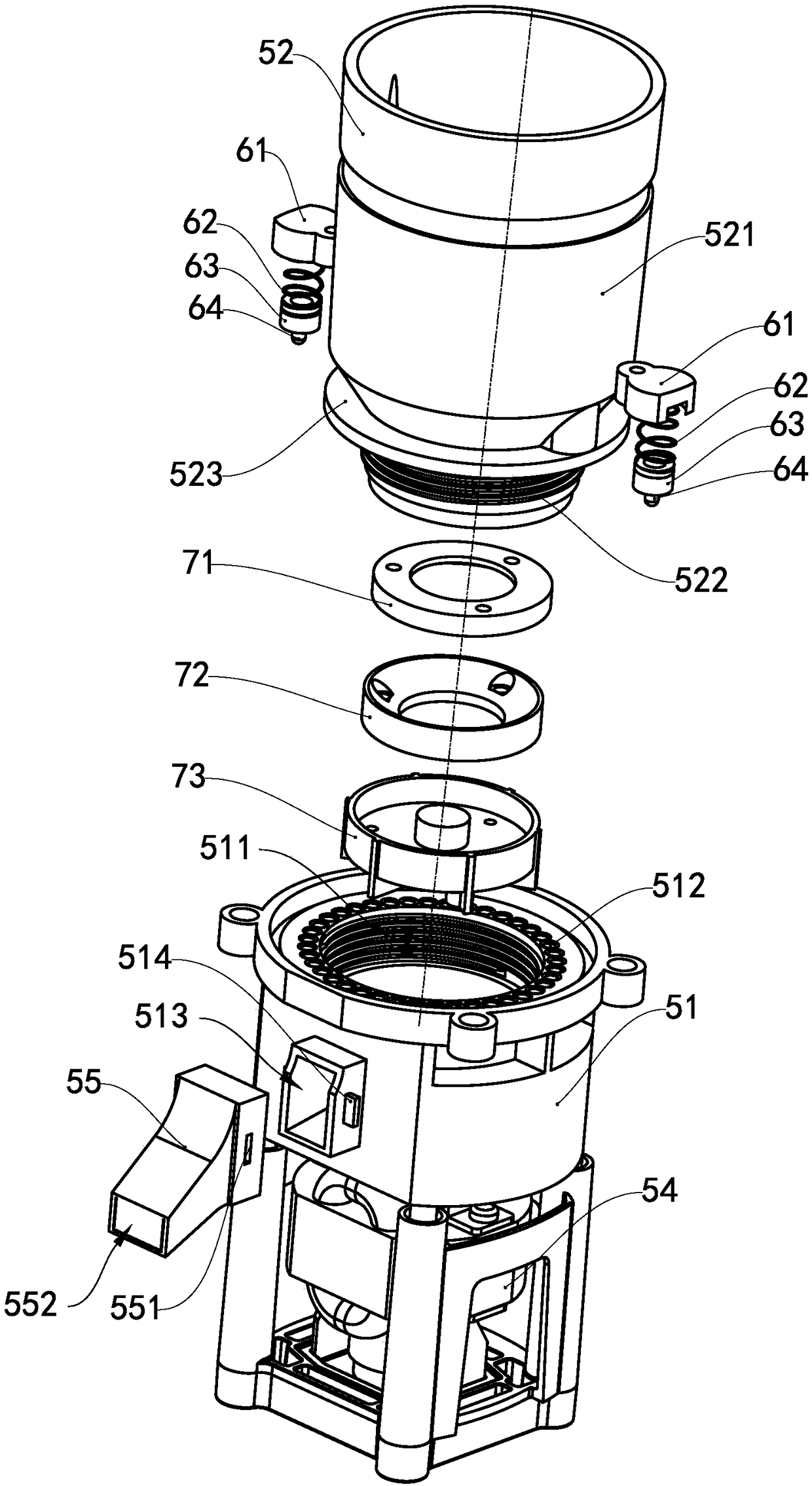

[0039] see Figure 2 to Figure 5 The grinding unit 5 includes a grinding body assembly and a bean box 52. The grinding body assembly includes a grinding body 51, a motor 54, and an upper grinding wheel 71, a lower grinding wheel 72 and a lower grinding wheel mounting bracket 73 arranged coaxially. A grinding chamber 511 is provided in the grinding body 51 . The bean box 52 includes a cylinder body 521 and a mounting portion 522 located at an axial end of the cylinder body 521 . The mounting portion 522 is connected to the grinding body 51 through threads. Two elastic clamping devices are arranged on the cylinder body 521 , and the two elastic clamping devices are arranged symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com