Assembly type continuous box girder hogging moment steel cable anchoring area structure and construction method thereof

A prefabricated, negative bending moment technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of low tensioning efficiency, affecting beam penetration, grouting, and occupation of pavement space, etc., to achieve convenient tensioning Pulling, improving the force of the later stage, and improving the effect of structural force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

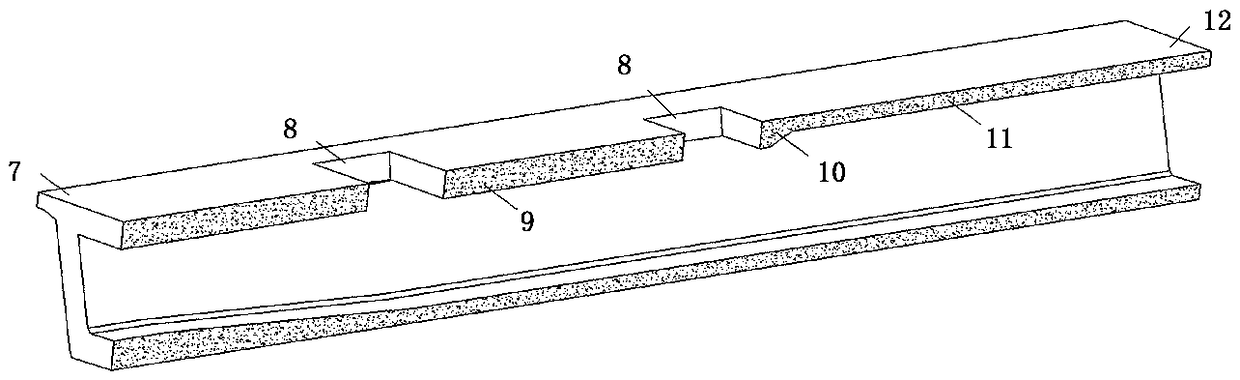

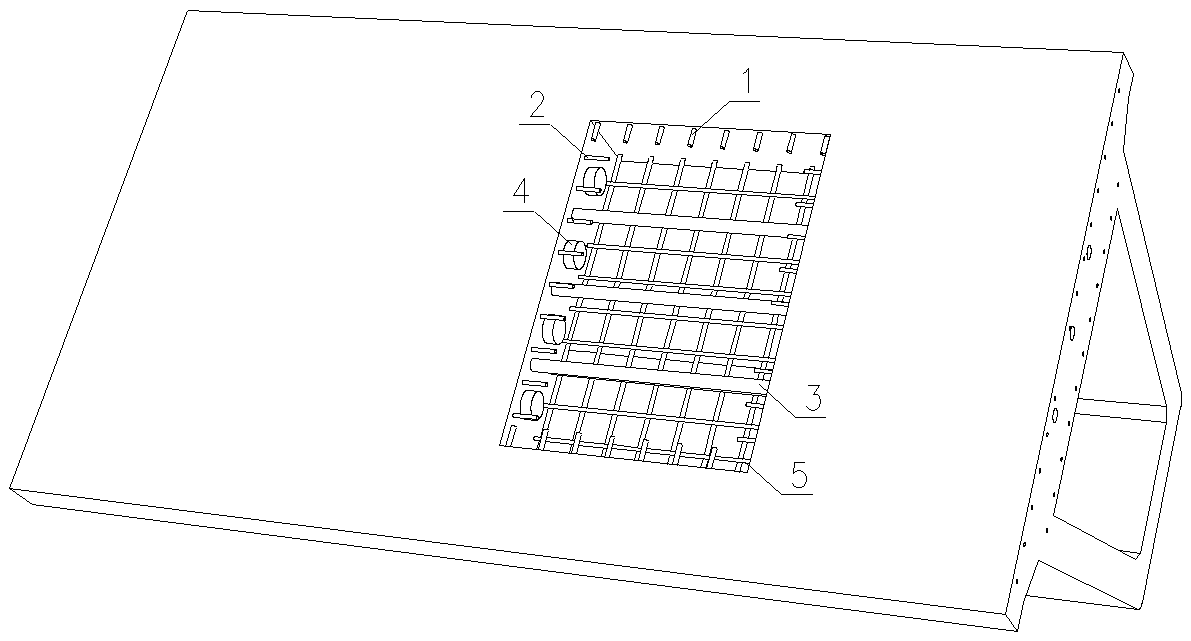

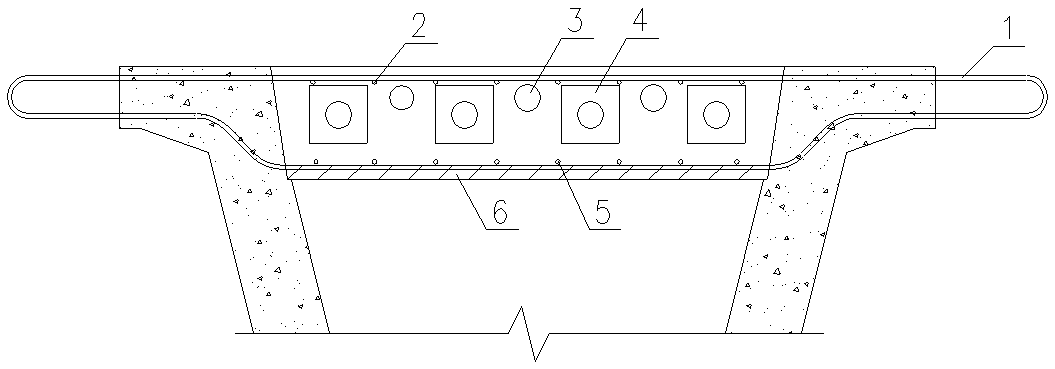

[0029] The invention relates to an anchorage area structure of an assembled continuous box girder negative moment steel beam, which comprises a prefabricated box girder, a prefabricated box girder top plate thickening section is arranged on the prefabricated box girder top plate, and the prefabricated box girder top plate is thickened A sloped prefabricated box girder thickness transition section is arranged between the section and the normal section of the prefabricated box girder roof. The thickened section of the prefabricated box girder roof is provided with steel beam tensioning reserved grooves 8; the thickened section of the prefabricated box girder roof is provided with horizontal and vertical reinforcement structures.

[0030] The horizontal and vertical steel bar structure includes a closed-loop bridge deck transversely stressed main bar 1, and the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com