Soft-package lithium battery preparation method capable of increasing energy density

A soft-pack lithium battery and energy density technology, applied in the field of energy storage, can solve the problems of volume energy density reduction, increase the volume of invalid areas, etc., and achieve the effect of increasing volume energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] This embodiment provides a method for preparing a soft-pack lithium battery with improved energy density, comprising the following steps:

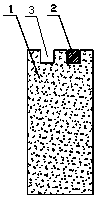

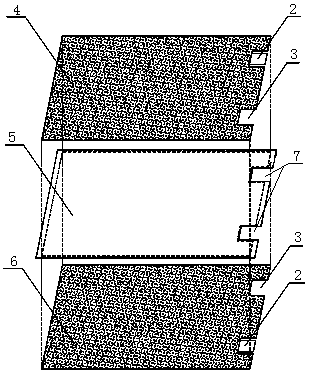

[0031] (1) Prepare the positive and negative pole pieces with the lug welding zone 2 and the pole piece vacancy zone 3 with a square groove structure at the edge, the specific structure of which is as follows figure 2 As shown, the tab welding area 2 is used for the welding of the tabs, and the pole piece vacancy area 3 is used for the alignment of the positive and negative pole pieces to facilitate the welding of the pole pieces.

[0032] The specific preparation process of the above-mentioned positive and negative electrode sheets is as follows: First, according to the designed electrode sheet specifications, the positive and negative electrode current collectors are respectively coated with the active layer 1 of the electrode sheet to form the positive and negative electrode sheets, wherein the positive electrode of the positive ...

Embodiment 1

[0043] Use an aluminum foil current collector to coat the active layer 1 of the positive electrode. The width of the coating area is 200 mm. At the first 100 mm of the coating area, paste tapes with a thickness of 100 um and a length and width of 24 mm and 12 mm along the center line at equal intervals of 60 mm. , the length direction of the tape is consistent with the coating width direction; after the material layer to be coated is dried, the previous tape is removed before winding, and the pole pieces are respectively punched along the two sides of the coating centerline area, and the pole piece size is width 50mm, length 100mm, the entire area of the uncoated area reserved on the aluminum foil current collector (that is, the tab welding area 2) is 12mm×12mm, and the distance from the width side of the pole piece is 8mm, and the tab welding area 2 and coating The 2.5mm wide and 11mm long area contacted by the pole piece active layer 1 in the length direction is punched and...

Embodiment 2

[0048] Use an aluminum foil current collector for positive electrode coating. The width of the coating area is 200mm. Paste a tape with a thickness of 100um and a length and width of 24mm and 12mm along the center line at an equal interval of 50mm at the first 100mm of the coating area. The length direction of the tape Consistent with the coating width direction; after the coated material layer is dried, remove the previous tape before winding, and cut it into pole pieces with a width of 100 mm and a length of 250 mm along the center line of the coating. Among them, the tab welding area 2 The area of the pole piece vacancy area 3 is 12mm×12mm. After being punched by a die-cutting machine, it is punched in sequence according to the pole piece vacancy area 3 and the tab welding area 2. The final pole piece effect is that two adjacent pole pieces are vacant. The distance between area 3 or two adjacent tab welding areas 2 is 16mm, the distance between tab welding area 2 and pole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap