Metal plate dust removal apparatus

A technology of dust removal equipment and plates, which is applied in the field of hardware plate dust removal equipment, can solve the problems of insufficient dust removal, affecting health, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

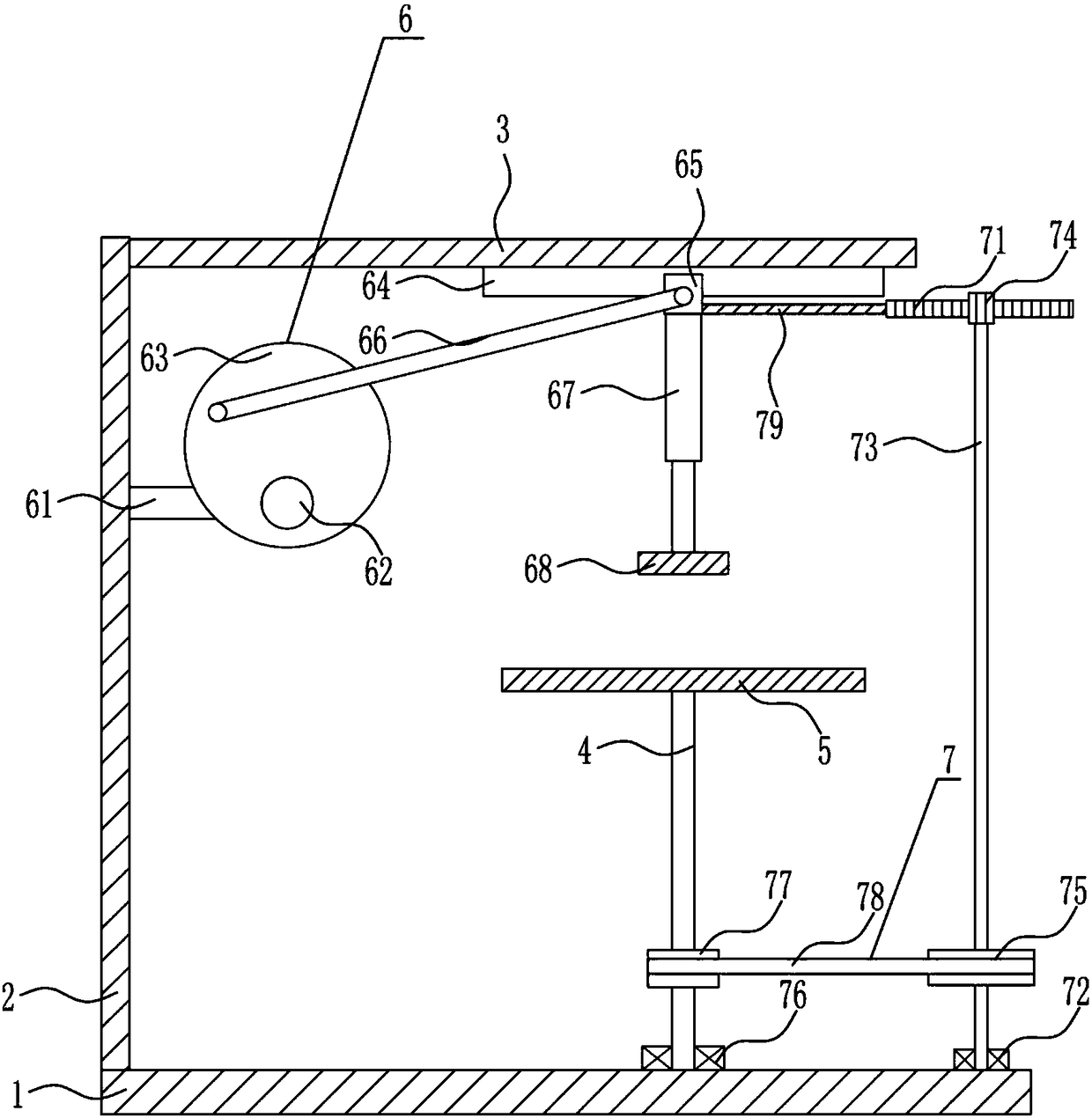

[0029] A metal plate dust removal equipment, such as Figure 1-4 As shown, it includes a base plate 1, a left bracket 2, a top plate 3, a vertical rod 4, a placement plate 5, a dust removal mechanism 6, and a rotating mechanism 7. The left bracket 2 is provided on the left side of the top of the base plate 1, and a vertical rod is provided in the middle of the top of the base plate 1. 4. There is a placement plate 5 on the top of the vertical rod 4, a top plate 3 on the upper right side of the left bracket 2, a dust removal mechanism 6 on the bottom of the top plate 3, and a rotation mechanism 7 on the right of the bottom plate 1.

Embodiment 2

[0031] A metal plate dust removal equipment, such as Figure 1-4 As shown, it includes a base plate 1, a left bracket 2, a top plate 3, a vertical rod 4, a placement plate 5, a dust removal mechanism 6, and a rotating mechanism 7. The left bracket 2 is provided on the left side of the top of the base plate 1, and a vertical rod is provided in the middle of the top of the base plate 1. 4. There is a placement plate 5 on the top of the vertical rod 4, a top plate 3 on the upper right side of the left bracket 2, a dust removal mechanism 6 on the bottom of the top plate 3, and a rotation mechanism 7 on the right of the bottom plate 1.

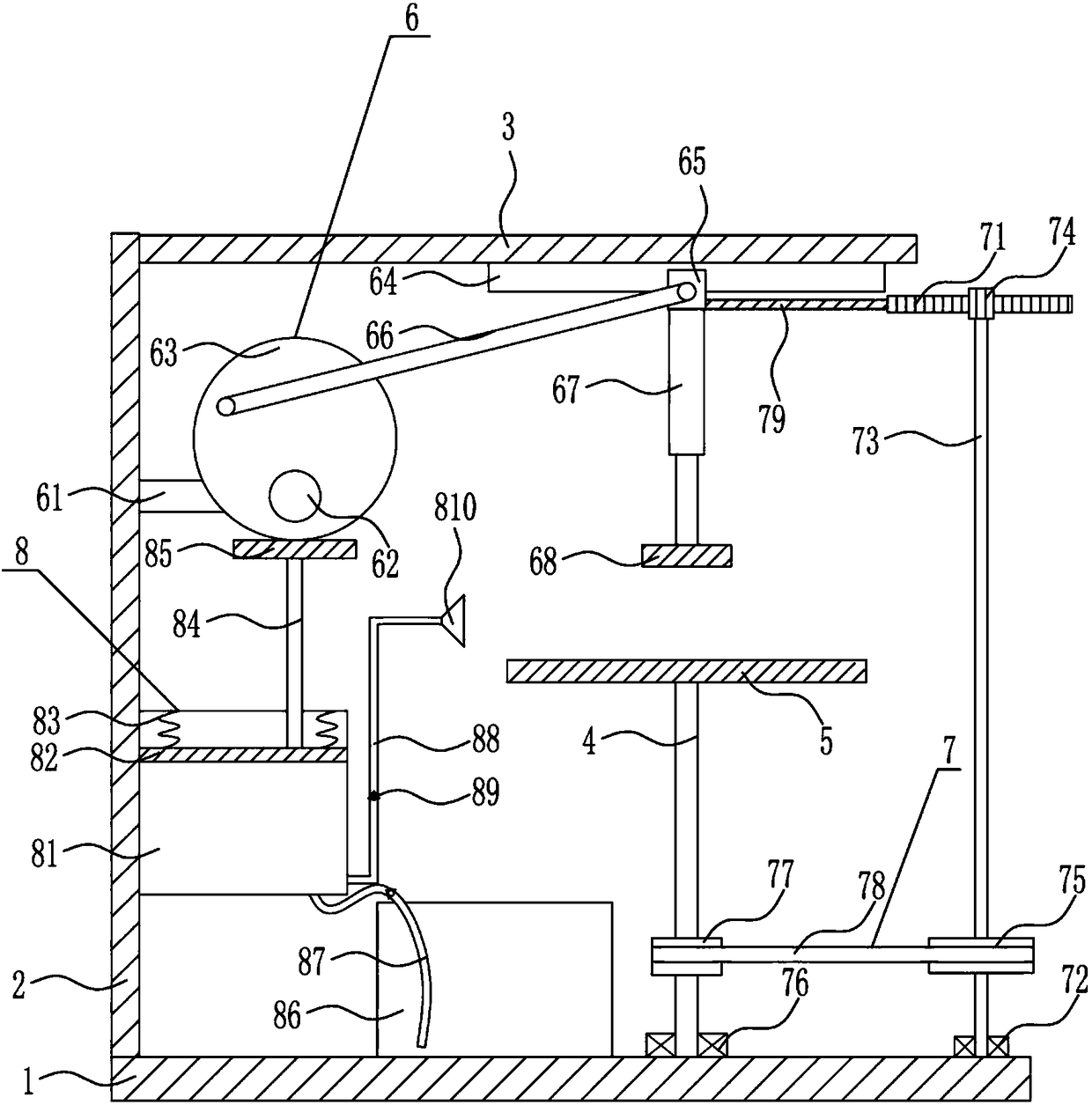

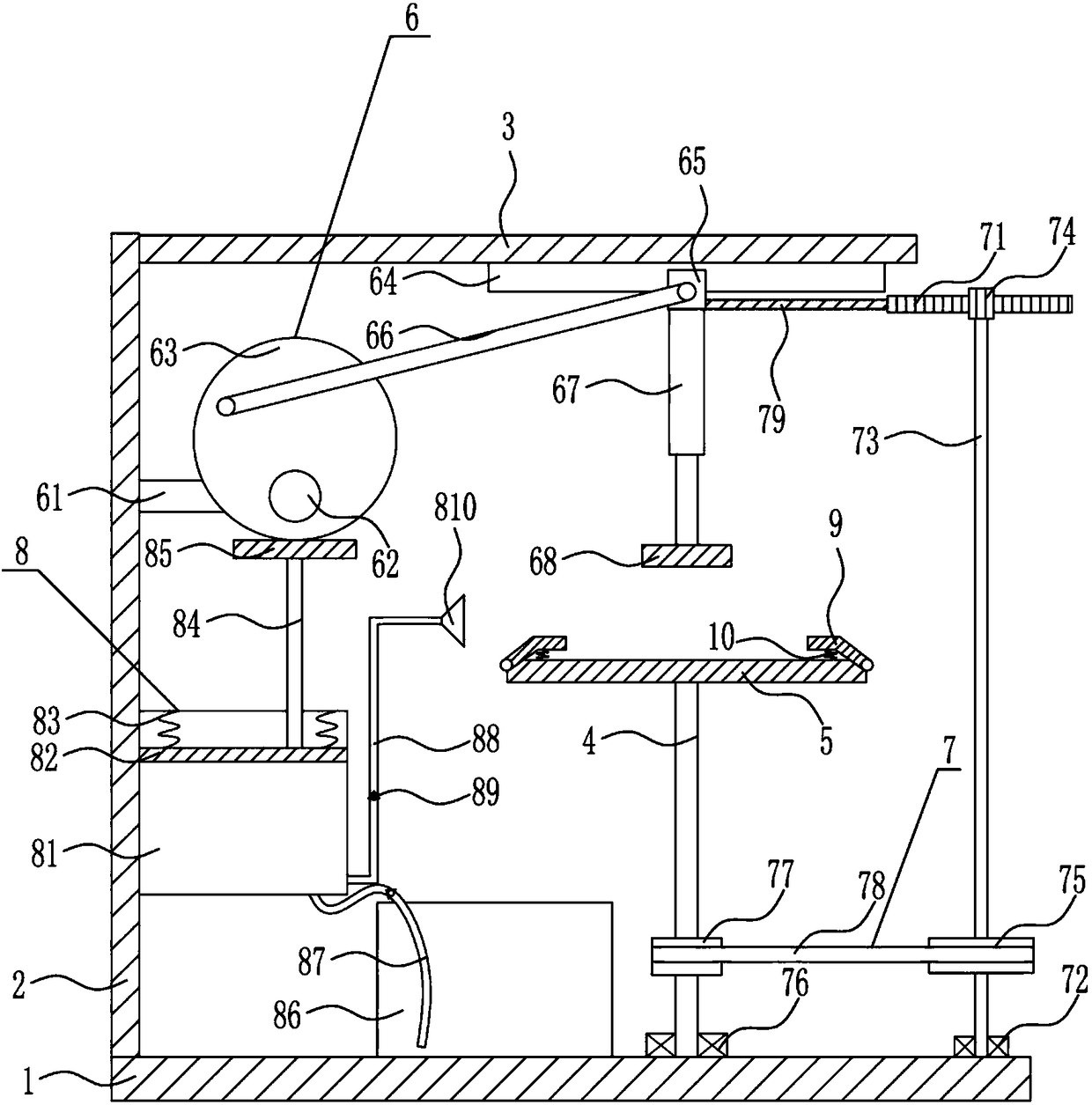

[0032] The dust removal mechanism 6 includes a pole 61, a motor 62, a disk 63, a slide rail 64, a slide block 65, a connecting rod 66, an electric push rod 67 and a wiping block 68, and the left support 2 right side upper part is provided with a pole 61, and The right end of the rod 61 is provided with a motor 62, the output shaft of the motor 62 i...

Embodiment 3

[0034] A metal plate dust removal equipment, such as Figure 1-4 As shown, it includes a base plate 1, a left bracket 2, a top plate 3, a vertical rod 4, a placement plate 5, a dust removal mechanism 6, and a rotating mechanism 7. The left bracket 2 is provided on the left side of the top of the base plate 1, and a vertical rod is provided in the middle of the top of the base plate 1. 4. There is a placement plate 5 on the top of the vertical rod 4, a top plate 3 on the upper right side of the left bracket 2, a dust removal mechanism 6 on the bottom of the top plate 3, and a rotation mechanism 7 on the right of the bottom plate 1.

[0035] The dust removal mechanism 6 includes a pole 61, a motor 62, a disk 63, a slide rail 64, a slide block 65, a connecting rod 66, an electric push rod 67 and a wiping block 68, and the left support 2 right side upper part is provided with a pole 61, and The right end of the rod 61 is provided with a motor 62, the output shaft of the motor 62 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com