Uncaria cutting equipment

A technology of cutting and uncaria is applied in the field of plant cutting equipment, which can solve the problems of unstable cutting efficiency of cutting equipment, high labor intensity and low efficiency of manual cutting, and achieves reduction of labor intensity and low production cost. , Stable effect of cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

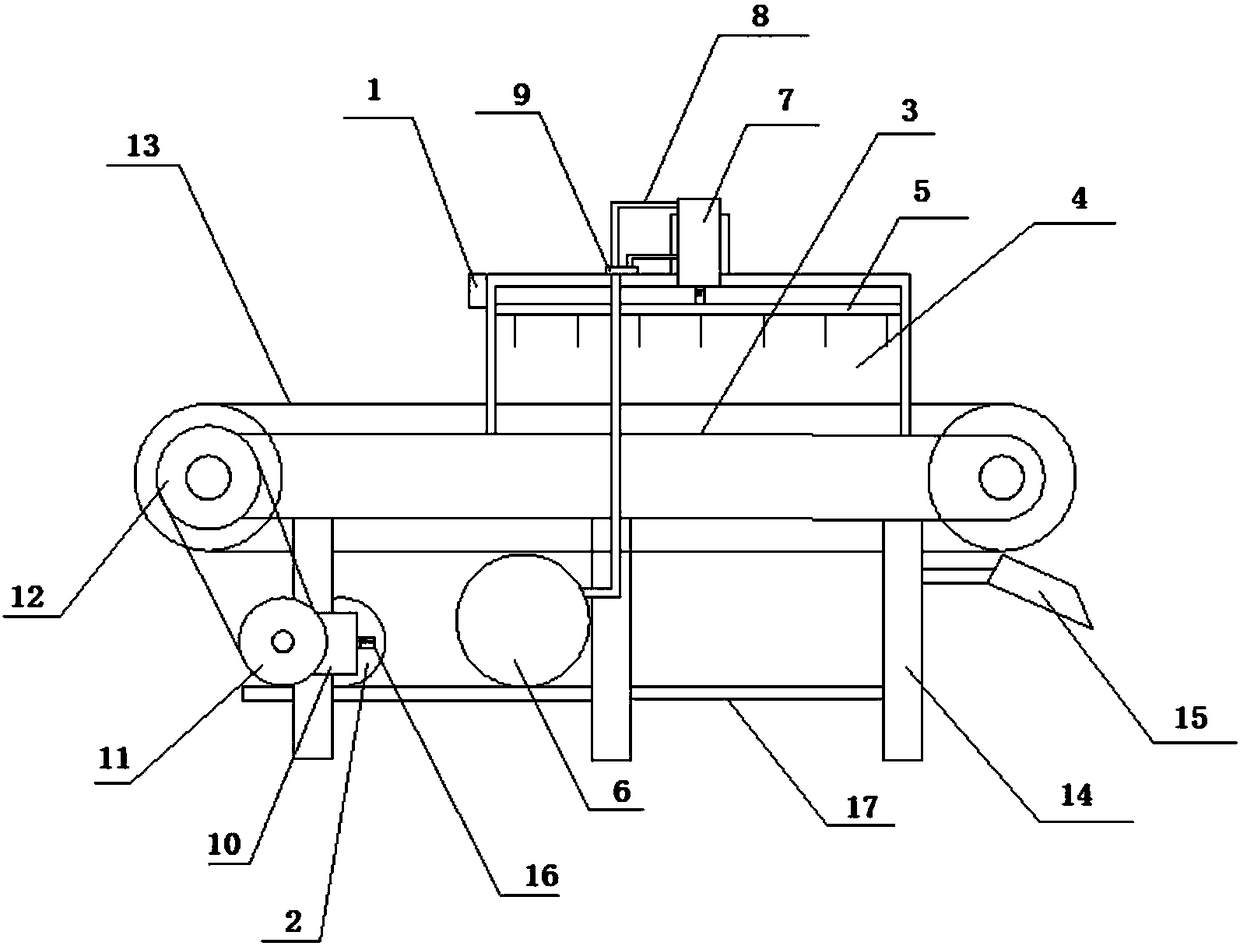

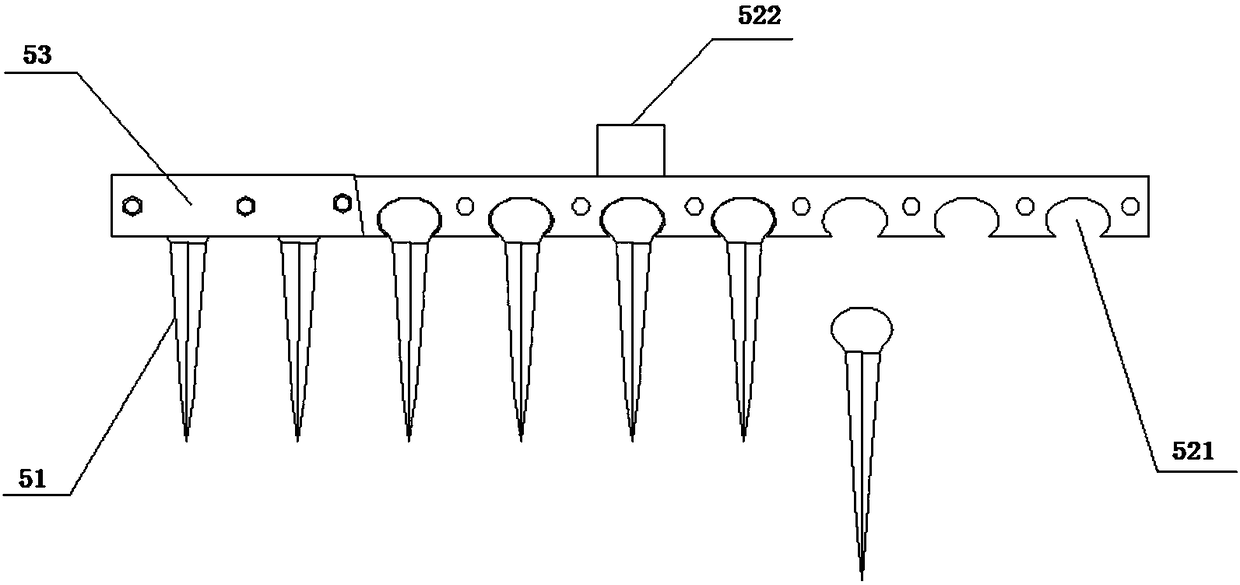

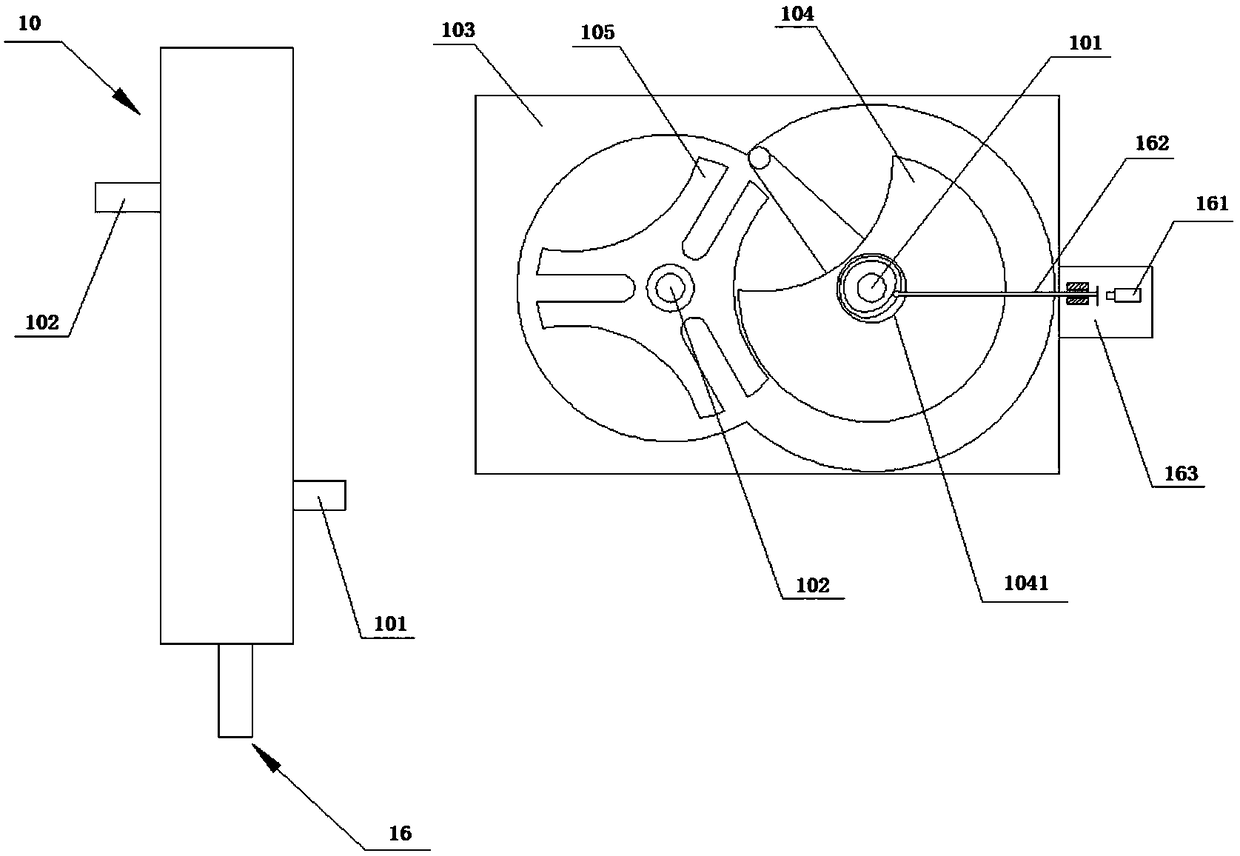

[0020] refer to Figure 1-3 , Uncaria cutting equipment, including control panel 1, motor 2, worktable 3, cutting room 4, cutter 5, air compressor 6, cylinder 7, air pipe 8, solenoid valve 9, conversion box 10, driving wheel 11, Driven wheel 12, conveyor belt 13, pillar 14, hopper 15 and telescopic control block 16, said cutting section 4 is fixedly installed on the upper right of workbench 3 by bolts, and said cutter 5 can be freely moved up and down and installed in cutting section 4, the cylinder 7 is fixedly installed in the middle position of the top of the cutting room 4 by bolts, and one end of the cylinder 7 extends into the cutting room 4, the cutter 5 is connected to the cylinder 7 by bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com