An eds support system for vacuum tube maglev train

A technology for maglev trains and vacuum pipes, applied in tunnel systems, sliding/floating railway systems, roads, etc., can solve the problems of poor stability, complicated manufacturing, installation, and maintenance, and high cost of discrete induction rails, achieving good stability, The effect of strong reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings, but is not limited to the content described below.

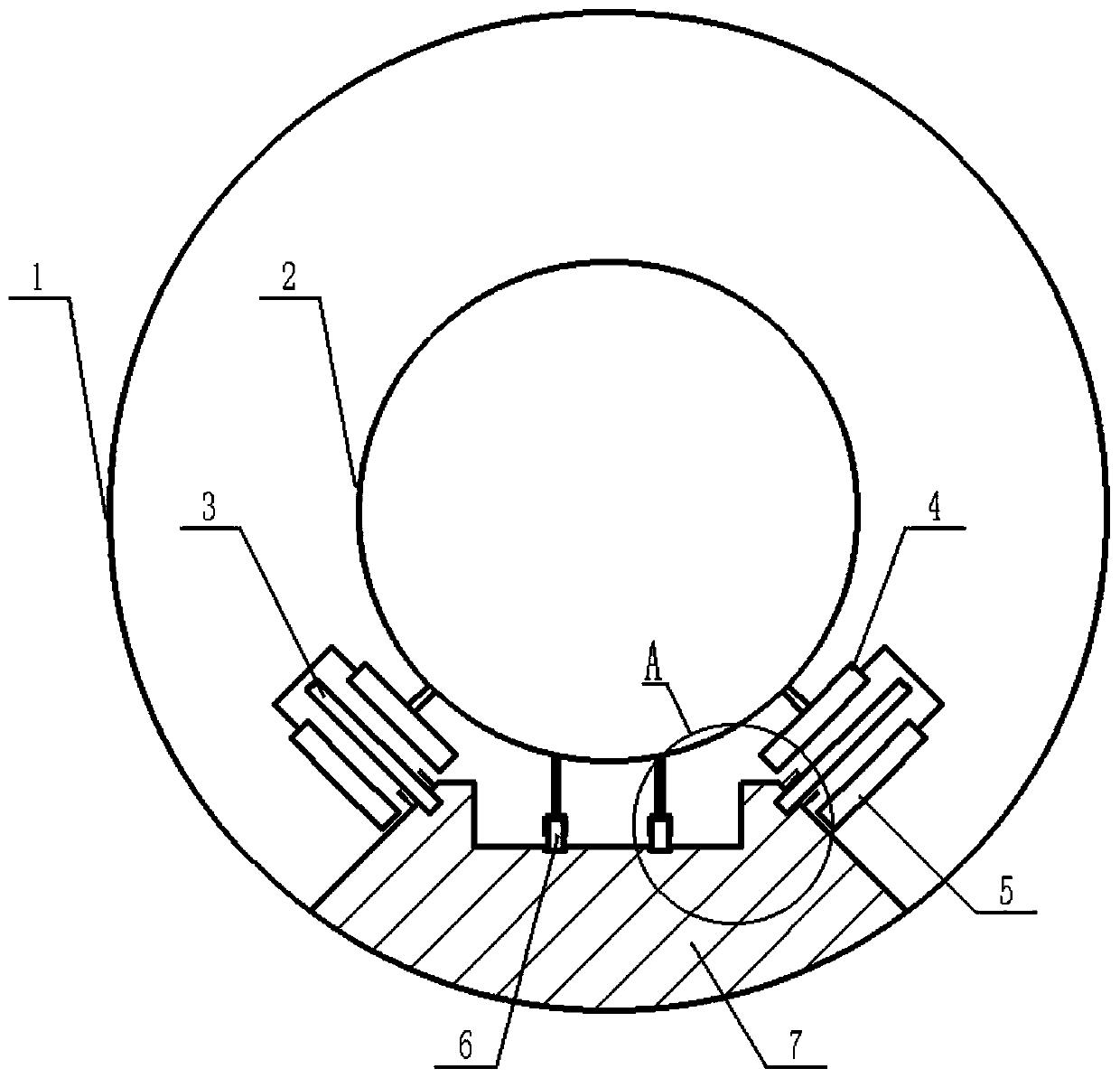

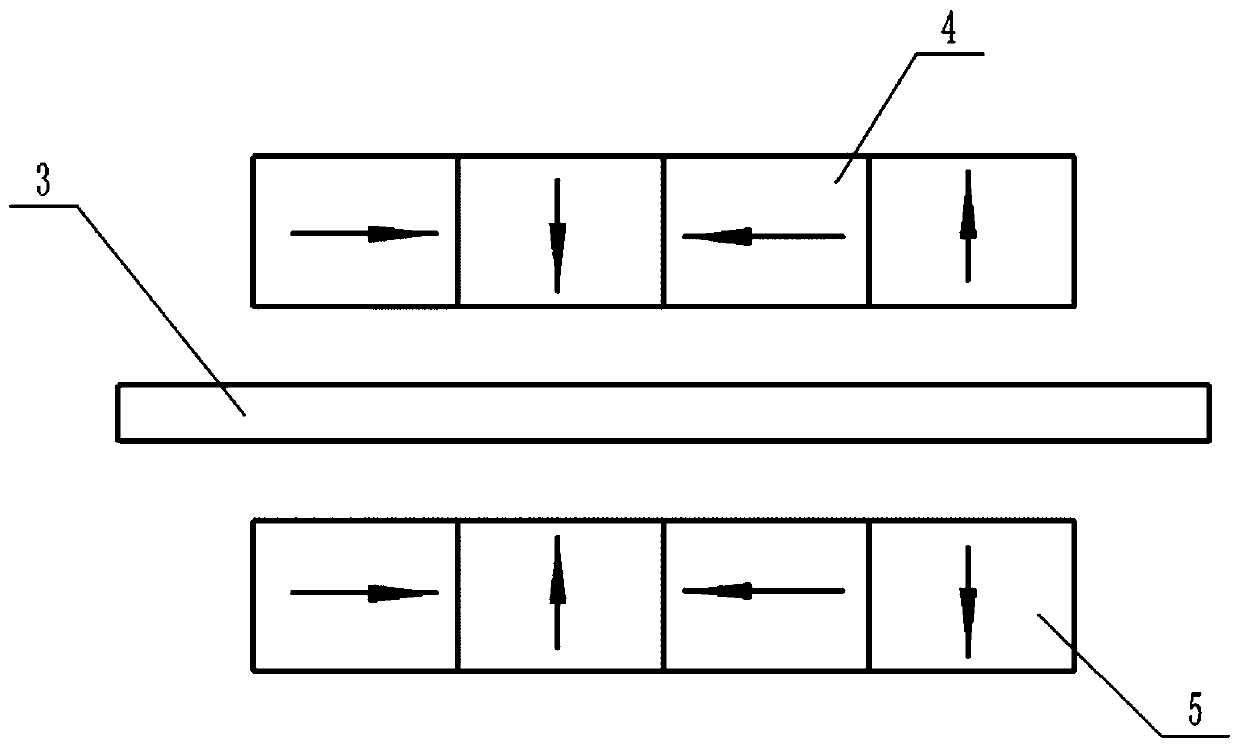

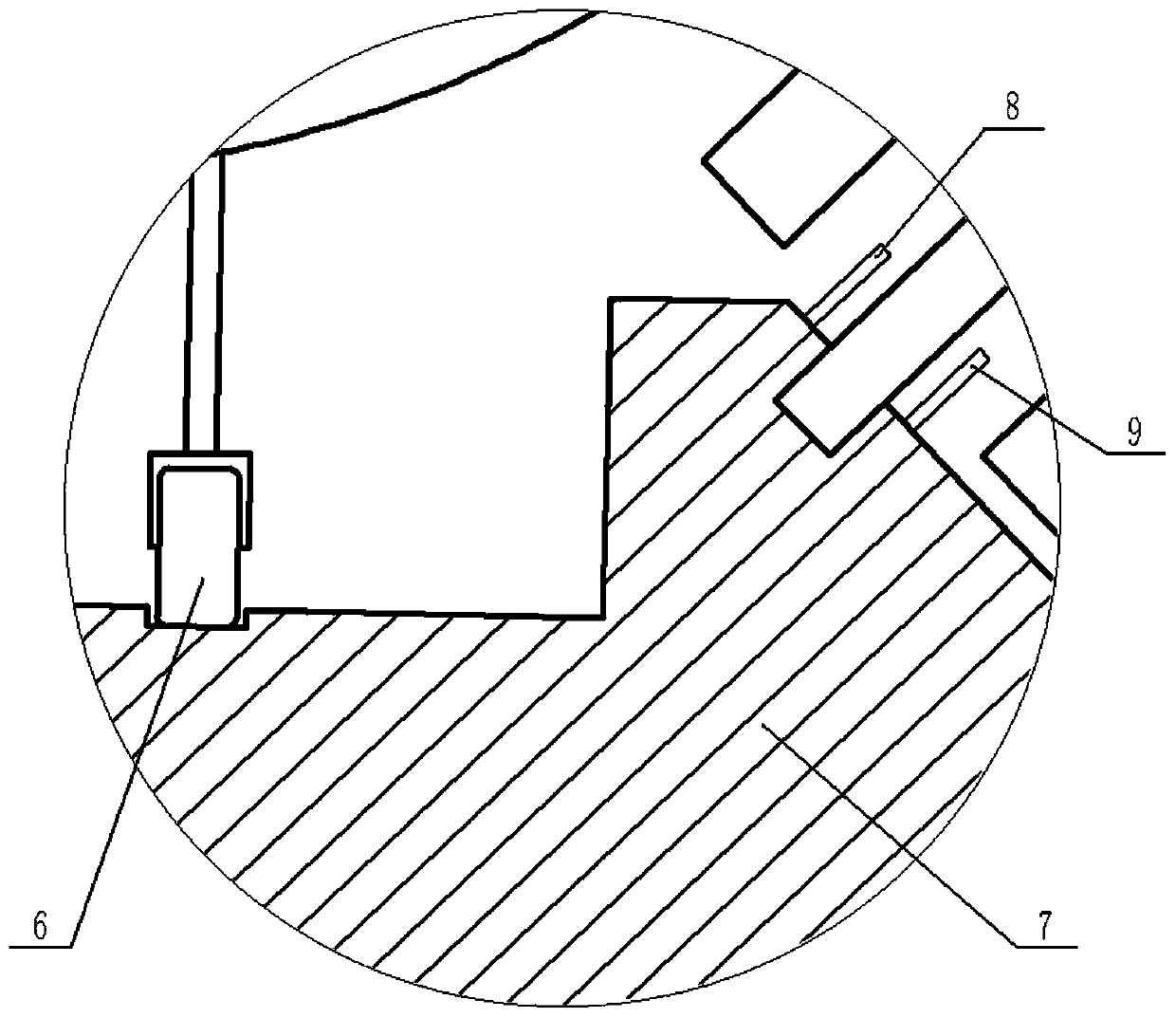

[0030] refer to figure 1 and figure 2 , the embodiment of the present invention provides a magnetic levitation EDS support system for a vacuum tube train, which is characterized in that: a circular train 2 with a circular cross section is set in a circular vacuum tube 1; bilateral straight lines are set on both sides of the lower half of the train 2 Type permanent magnet Halbach array (including two unilateral linear permanent magnet Halbach arrays arranged up and down oppositely) and induction plate 3; bilateral linear permanent magnet Halbach array includes unilateral linear upper permanent magnet Halbach array 4 and The unilateral linear lower permanent magnet Halbach array 5, the two unilateral linear permanent magnet Halbach arrays (the upper permanent magnet Halbach array 4 and the lower permanent magnet Halbac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com