Rapid battery-replacing system for electric vehicle

A technology of electric vehicles and electric systems, applied in the direction of electric power devices, vehicle maintenance, power devices, etc., can solve the problems of large footprint, low positioning accuracy, and long occupation time, so as to achieve fast disassembly and assembly speed and avoid misalignment The effect of installation and site cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

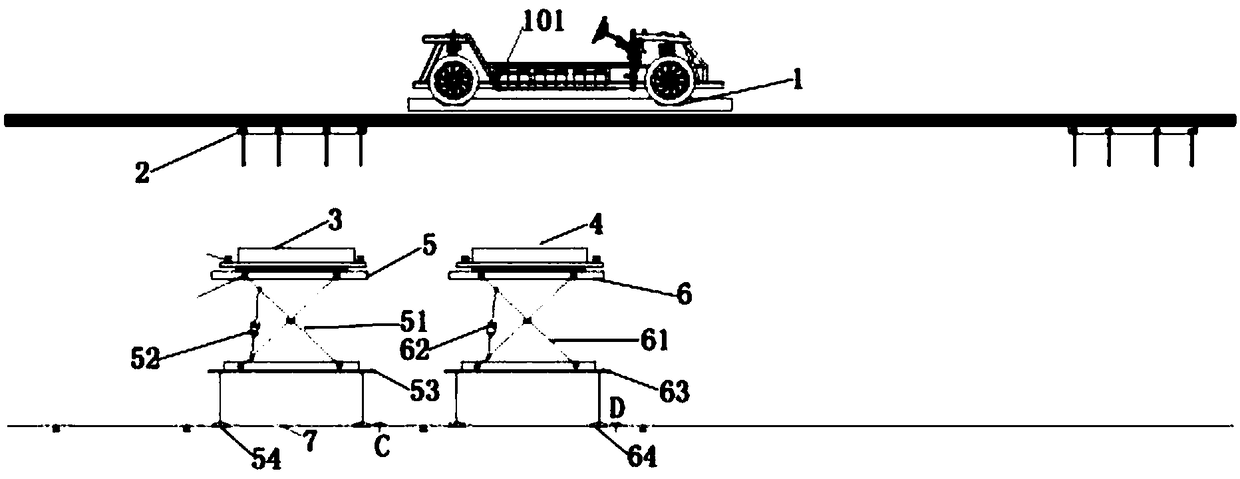

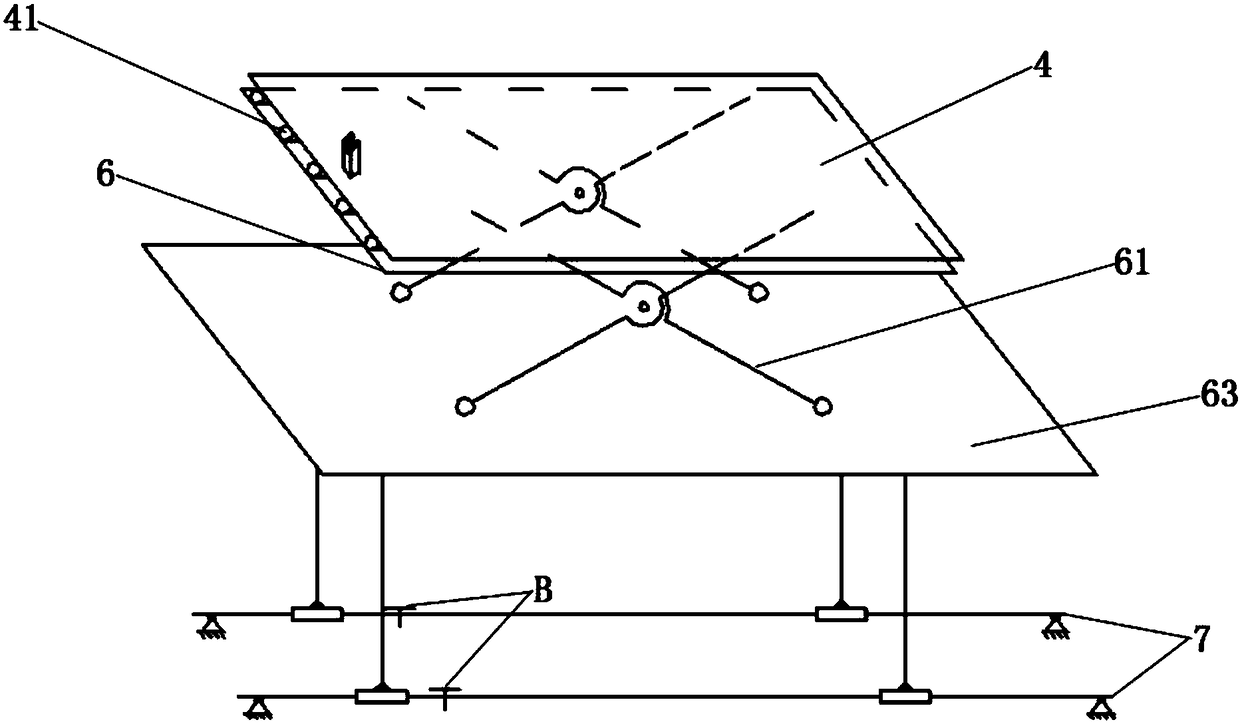

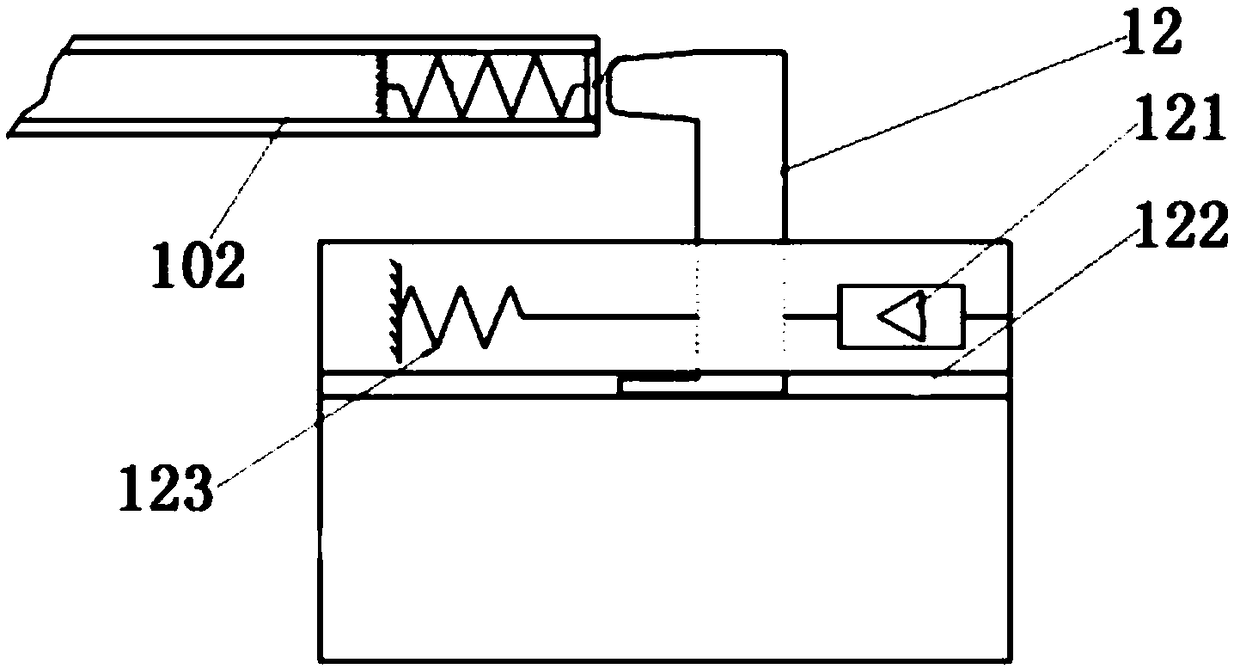

[0031] A fast battery swapping system for an electric vehicle, such as Figure 1-3As shown, it includes a frame fixing device, a dismounting mechanism 4, an installation mechanism 3, a hoisting mechanism 2 and a running water raceway, the vehicle frame fixing device is installed above the running water raceway, and the dismounting mechanism 4 and the installing mechanism 3 are respectively It is installed on the lifting platform located in the inner track of the running water raceway, and a hoisting mechanism is arranged above the dismounting mechanism 4 and the installing mechanism. The vehicle frame fixing device is installed on the ground, and the lifting platform, the dismantling mechanism 4, the installation mechanism 3, the hoisting mechanism 2 and the running water raceway are all installed underground, which can save site costs. The frame fixing device is mainly responsible for fixing the position of the vehicle body after the vehicle enters the power exchange area. Th...

Embodiment 2

[0038] A quick power exchange system for an electric vehicle, the difference from Embodiment 1 is that the frame fixing device is set on a working platform above the ground, the working platform can be a support plate, the lifting platform and the running water The raceways are all installed on the ground and below the working platform, which can also save site costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com