Special rail device for rubbish station butt joint box

A garbage station and track technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of derailment of the box, difficulty in positioning the box on the pull-arm car, and the failure of the compression host to smoothly dock the box, etc., to achieve Reduce the difficulty of operation and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the drawings.

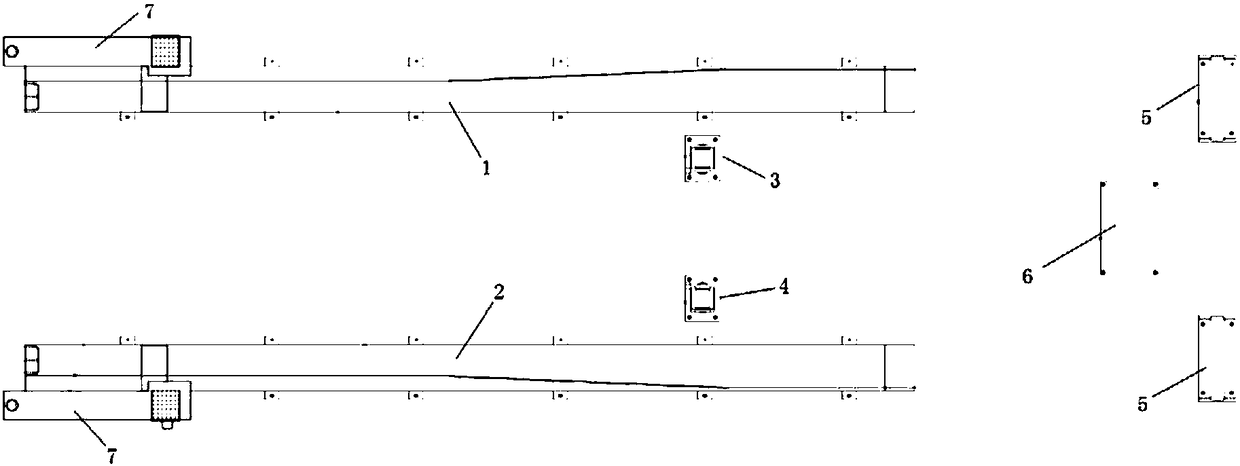

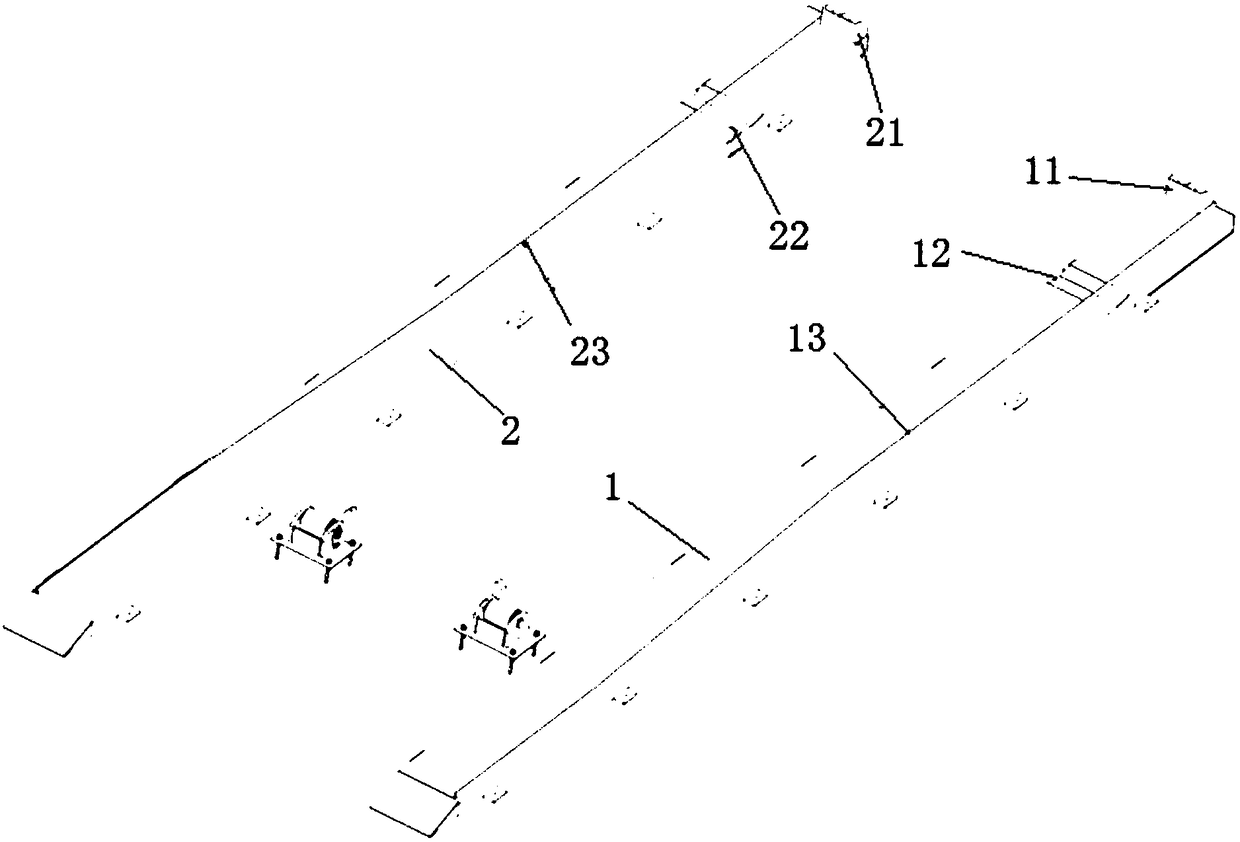

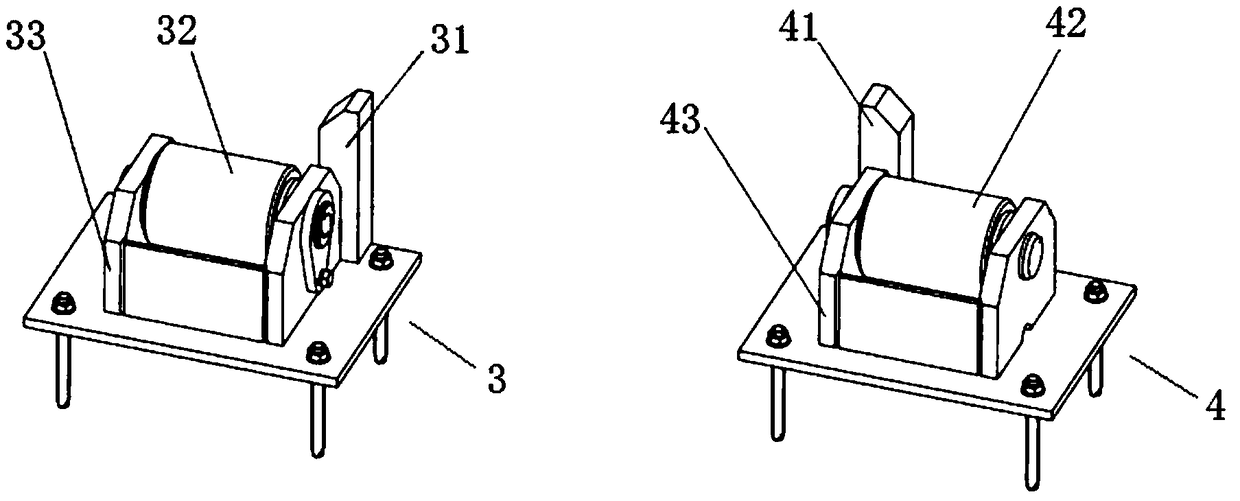

[0027] Such as figure 1 As shown, a special track device for a garbage station docking box includes a track beam, a roller support, a reverse stopper, a support pad and a sewage collection tank. The track beam includes parallel track left beam 1 and track right beam 2, the roller support includes a roller left support 3 and a roller right support 4, the roller left support 3 is arranged close to the track left beam 1, and the roller right support 4 is close to the track right The beam 2 is set; the reverse stopper 5 is provided with two, which are respectively located on the rear extension line of the left track beam 1 and the right track beam 2, and the support pad 6 is located between the track beam and the reverse stopper.

[0028] The track beam, the roller support, the reverse stopper 5 and the support pad 6 are all fixed on the ground by chemical anchor bolts.

[0029] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com