Method for controlling deformation during transverse hoisting of reinforcement cage

A control method and technology for steel cages, which are applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of falling steel cages, difficult lifting of steel cages, easy to produce collapse holes, etc., to reduce deformation and simple construction methods. Feasible and effective in improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by specific examples.

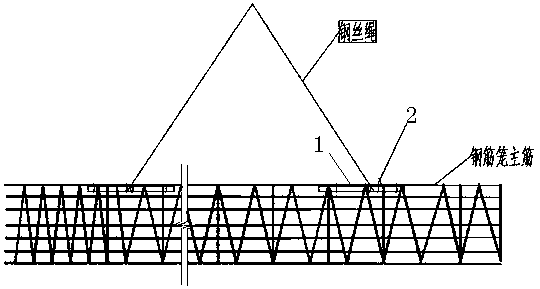

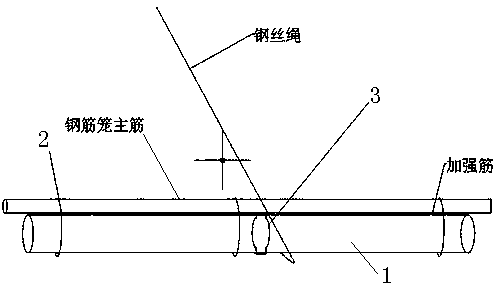

[0018] Such as figure 1 , figure 2 As shown, a method for controlling deformation of a steel cage during horizontal lifting, including a steel pipe 1, a two-way hook 2, a fastener 3 and a crane, the specific steps of the control method include

[0019] Step 1, making a reinforcement cage;

[0020] Step 2, set fasteners 3 on both ends of the steel pipe 1;

[0021] Step 3, inserting the steel pipe 1 with the fastener 3 into the two ends of the reinforcement cage respectively;

[0022] Step 4, use the two-way hook 2 to hook the fasteners at both ends of the steel pipe 1 and the main reinforcement of the steel cage respectively, so that the steel pipe is bound on the main reinforcement of the steel cage;

[0023] Step 4, thread the steel wire rope connected with the crane into the steel pipe,

[0024] Step 5, start the crane and carry out horizontal hoisting of the reinforcement cage.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com