Processing technology of biaxial stretching polyolefin shrinking film

A technology of biaxial stretching and processing technology, applied in the field of processing technology of biaxially stretched polyolefin shrink film, can solve the problems of loose molecular structure, low toughness and strength, and general effect, and achieve tight molecular structure, high toughness and strength, and not easy grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

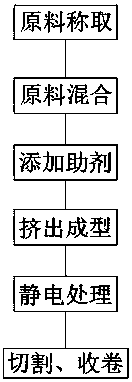

[0026] see figure 1 , the present invention provides a technical solution: a processing technology of biaxially stretched polyolefin shrink film, which mainly includes the following raw materials and their weight fractions: LLDPE (linear low density polyethylene) 35-50%, TPP (terpolymerization poly Propylene) 20-40%, PPC (two-component copolymerized polypropylene) 15-35%, necessary functional additives such as slip agent 5-10%, anti-blocking agent 10-20%, antistatic agent 5-15% wait.

[0027] The main components of the slippery agent are edible colloid, enzyme preparation and emulsifier.

[0028] The anti-blocking agent is mainly divided into organic anti-blocking agent and inorganic anti-blocking agent. The inorganic anti-blocking agent mainly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com