Advanced bath faucet

A faucet, plate technology, applied in multi-way valves, engine components, mechanical equipment, etc., can solve problems such as high price and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

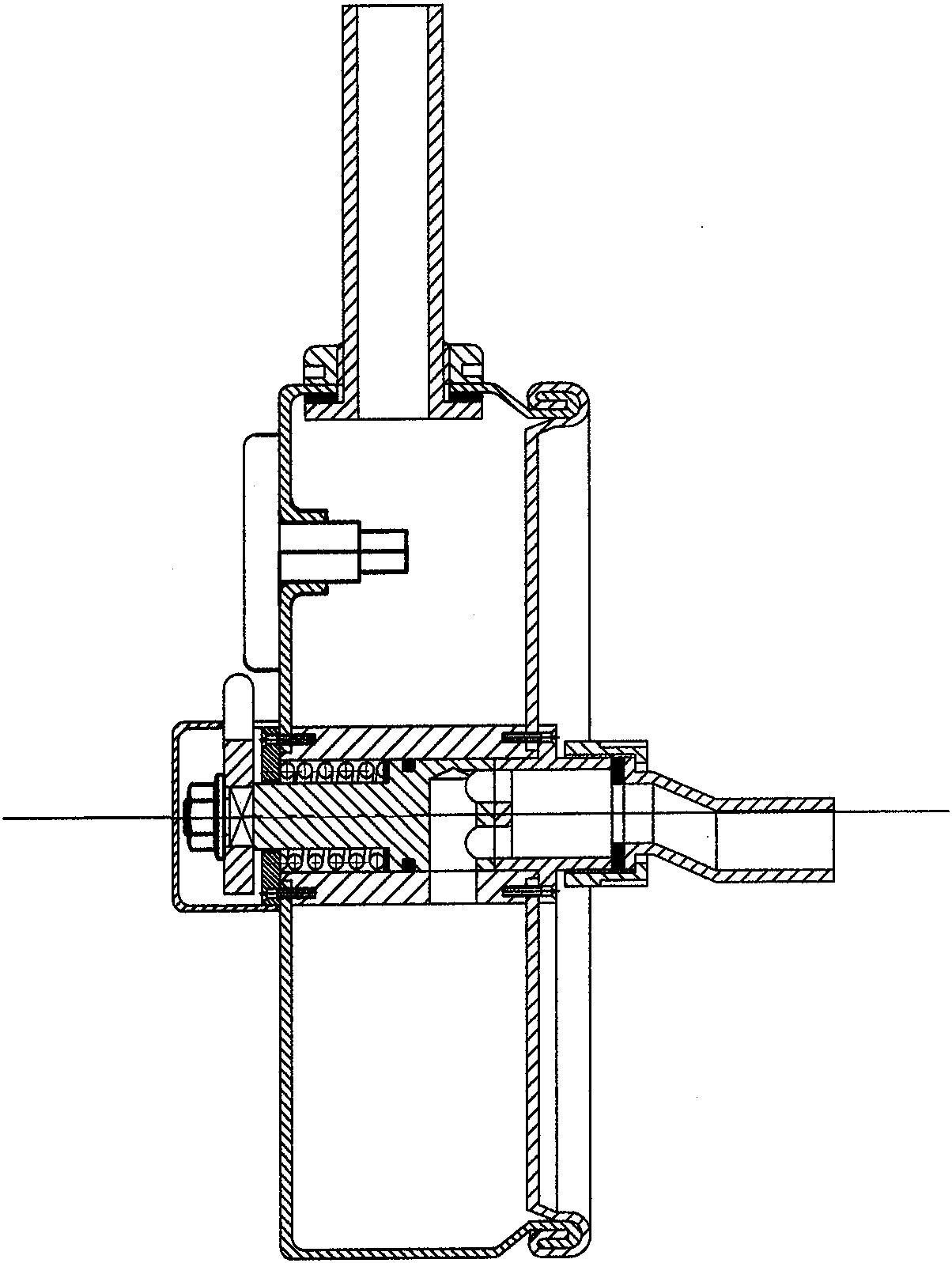

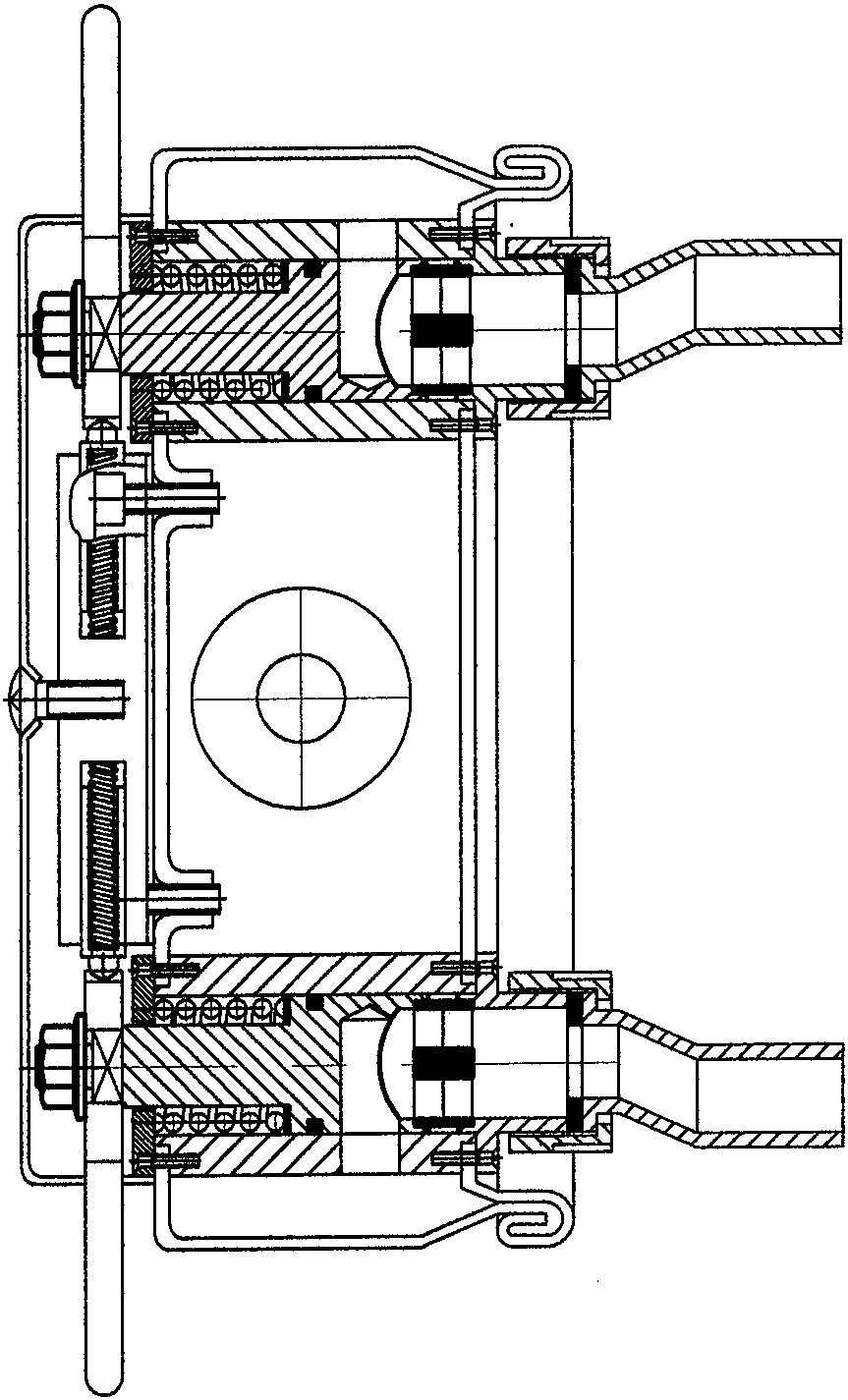

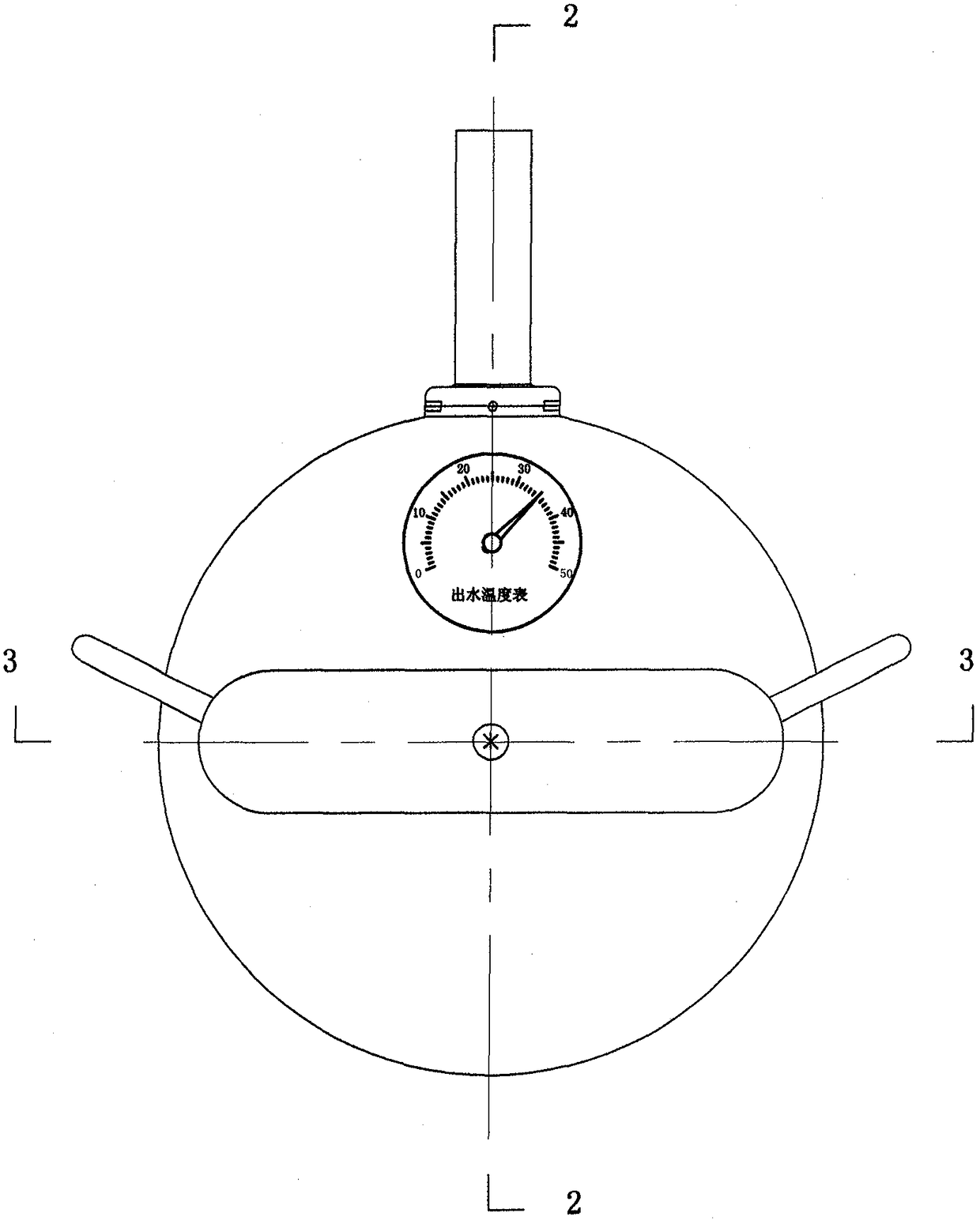

[0013] First, the plate is deep-drawn on a punching machine Figure 5 10 in to form a straight basin type jar, then punch in the bottom of the jar image 3 Two body mounting holes in and Figure 5 15 temperature gauge mounting holes in the and Figure 5 16 outlet pipe holes. followed by stamping Figure 5 12 caps in, also follow the Figure 5 After punching two valve body holes in 10. put out the water pipe Figure 5 16 into the housing Figure 5 on the 10 straight basin holes. Fits into two body housings Figure 5 7 of them. again Figure 5 10 of medium, covered Figure 5 In 12, carry out rolling and pressing, forming such as image 3 Finished bath faucet housing.

[0014] After the shower faucet shell is finished, such as Figure 5 ,install Figure 5 15 thermometers in the middle, install the fixed valve core on the cover plate Figure 4 In 8, insert the sealing gasket and tighten it with four screws, and then insert the sealing ring between the input pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com