Stop valve suitable for mold temperature machine

A globe valve, mold temperature machine technology, applied in the direction of control valve, valve device, mechanical equipment, etc., can solve the problems of limiting the development of injection mold temperature control technology, unstable output pressure of globe valve, poor sealing performance at high temperature and low temperature, etc. The effect of reducing heat loss, improving service life and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

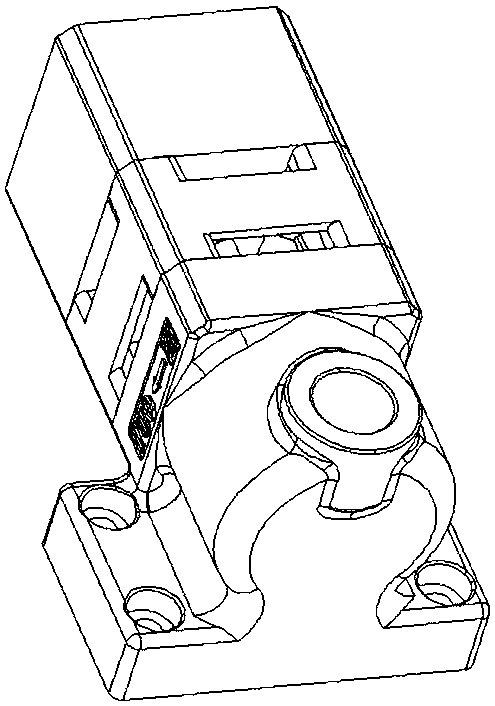

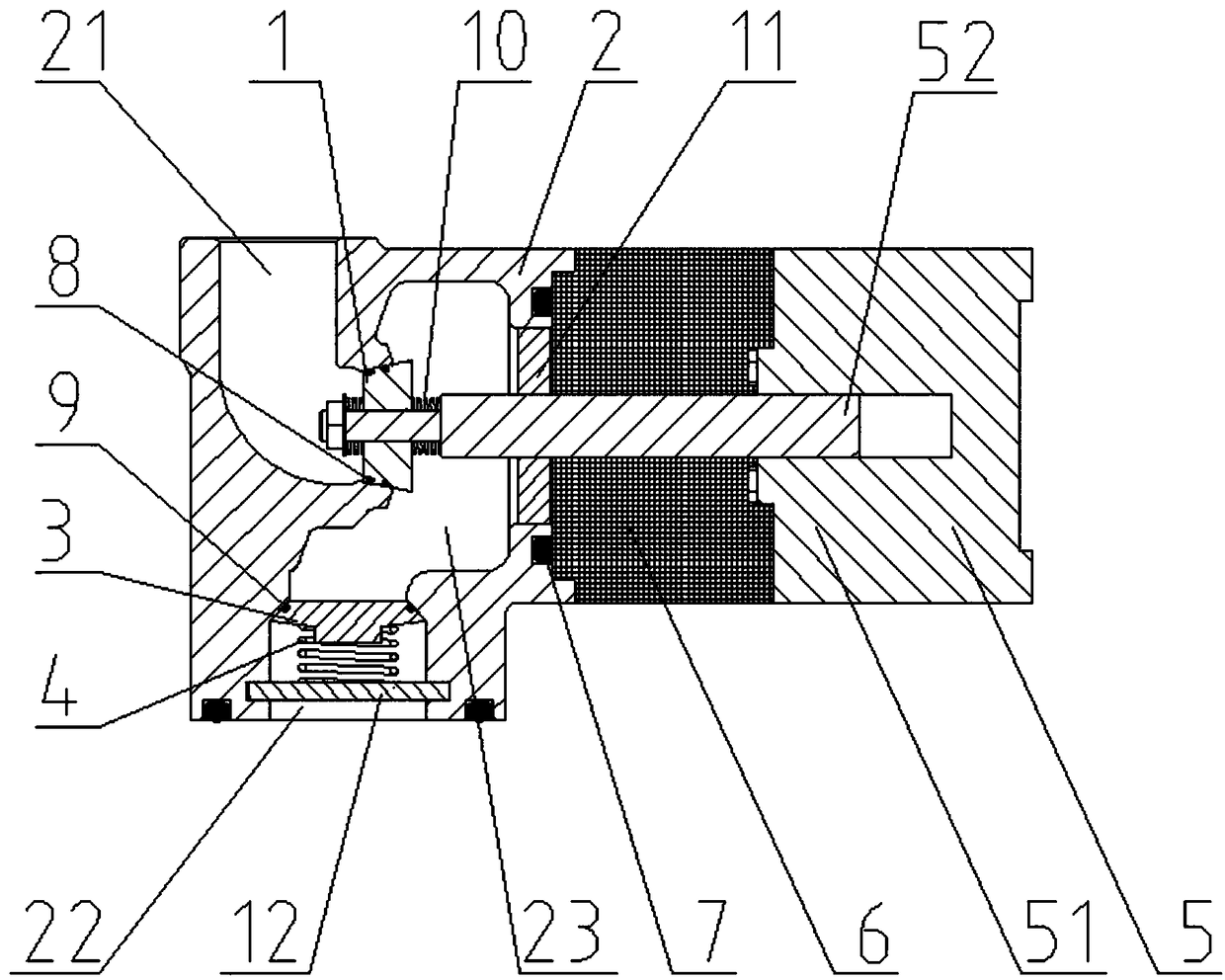

[0026] The content of the present invention will be further described in detail below in conjunction with specific embodiments. figure 1 , figure 2 A three-dimensional schematic view and a cross-sectional view of the shut-off valve adapted to the mold temperature controller in the present invention are respectively shown. The cut-off valve includes a valve body 2 , and an inlet channel 21 and an outlet channel 22 arranged in the valve body 2 . A transition chamber 23 is also provided in the valve body 2 , and the outlet channel 22 is always in direct communication with the transition chamber 23 . A closing valve 1 is provided between the inlet passage 21 and the transition chamber 23 , through which it is determined whether the inlet passage 21 communicates with the transition chamber 23 . A check valve 3 and a back pressure spring 4 connected thereto are arranged at the outlet of the outlet channel 22 , and the opening pressure of the check valve 3 can be adjusted by the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com