Stress optical cable underground laying and protection method used for transformer substation foundation displacement monitoring

A technology of displacement monitoring and underground laying, applied in the direction of optical device, optical fiber/cable installation, optical, etc., can solve problems such as soil erosion, ground cracking, affecting the safe and stable operation of the power grid, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

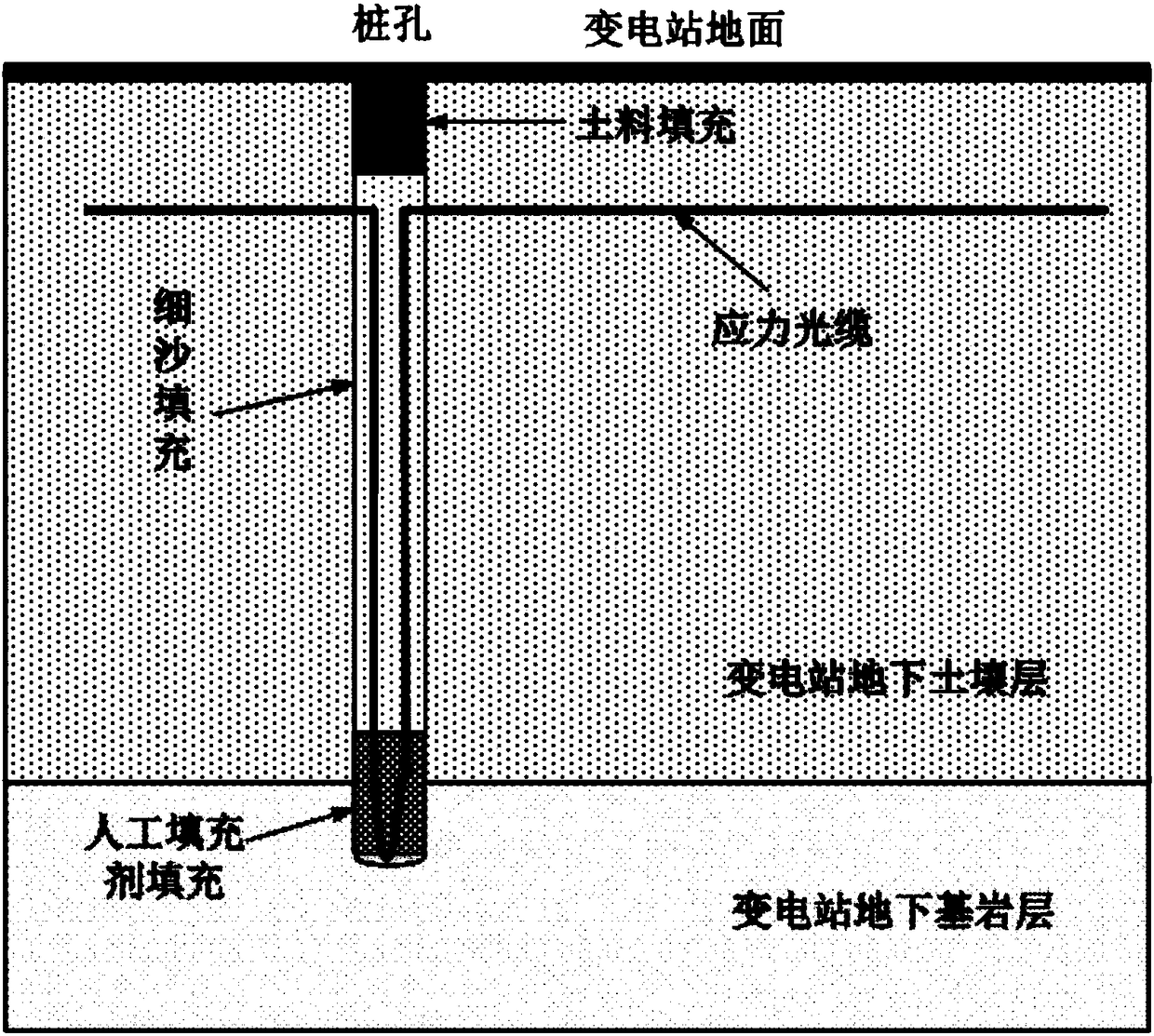

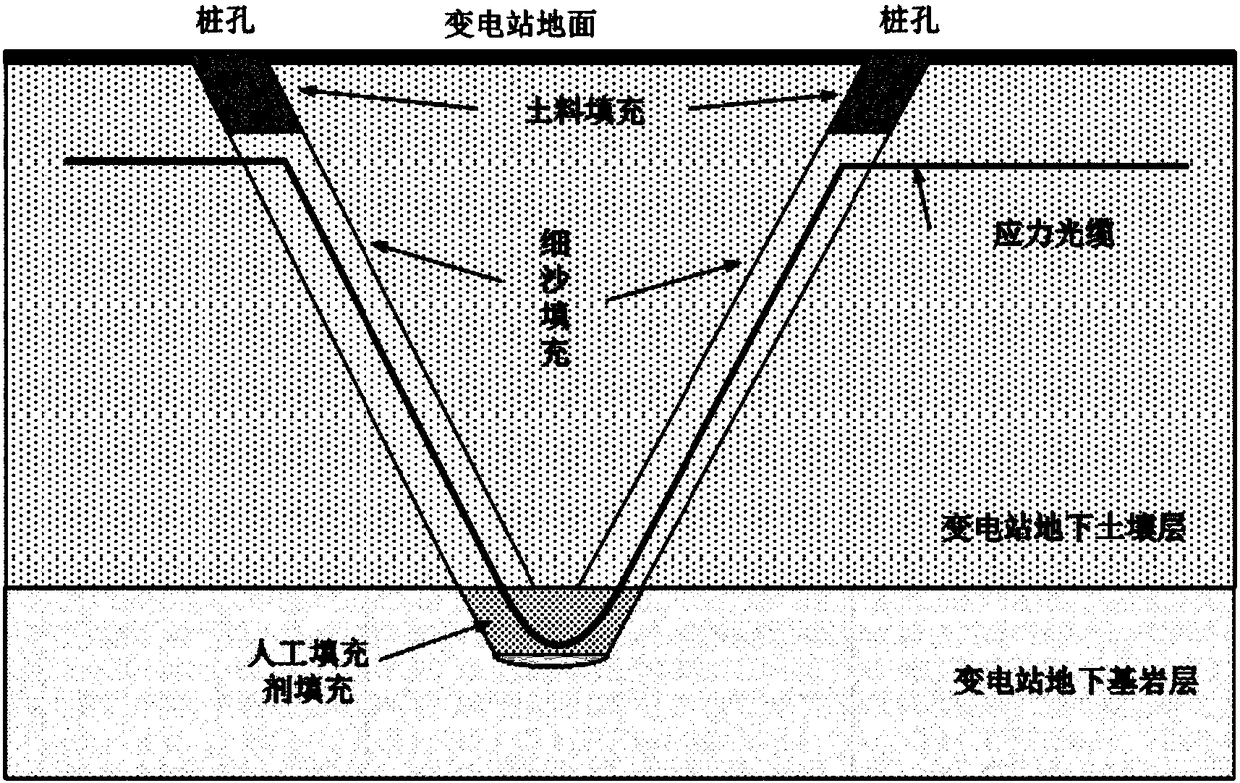

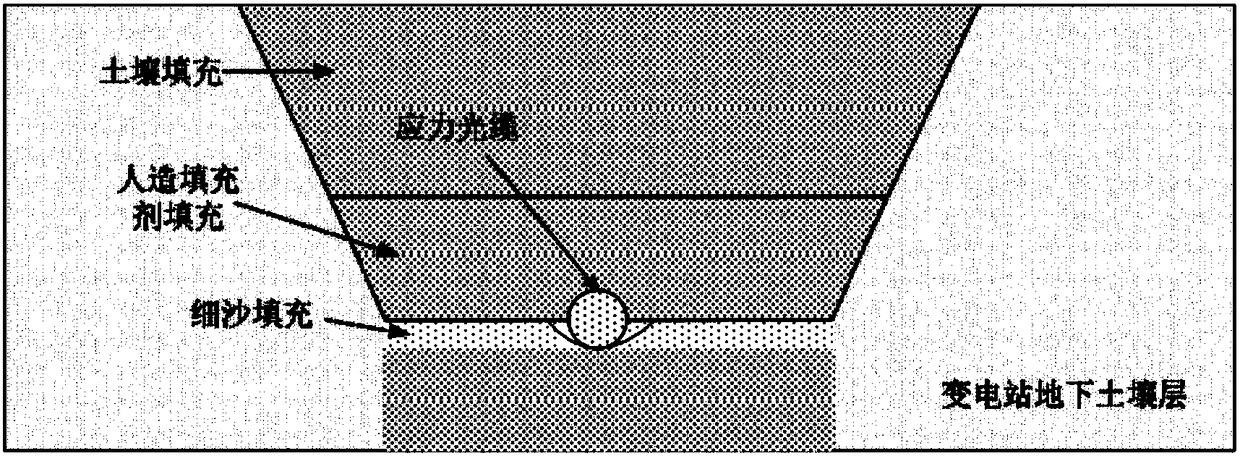

[0026] Such as figure 1 As shown, it is a schematic cross-sectional view of the method of underground laying of stress optical cables through pile holes perpendicular to the ground. figure 1 Among them, the pile hole is perpendicular to the ground, the depth of the pile hole passes through the soil layer of the foundation to the bedrock layer, and the depth of the optical cable into the ground also reaches the bedrock layer. The diameter of the pile hole meets the requirements of the bending curvature of the optical cable after entering the ground, which is equivalent to allowing the optical cable to enter the pile hole and then return to the ground after bending, that is, the diameter of the pile hole should be significantly larger than twice the diameter of the optical cable. When backfilling the pile hole after the optical cable is put into the ground, first use a certain amount of artificial filler to backfill the pile hole until the artificial filler completely covers the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com