Flower basket rapid rotation device

A rotating device and flower basket technology, which is applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve the problems that the flower basket 9 cannot meet the reversing requirements, and achieve high stability, reduce damage, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

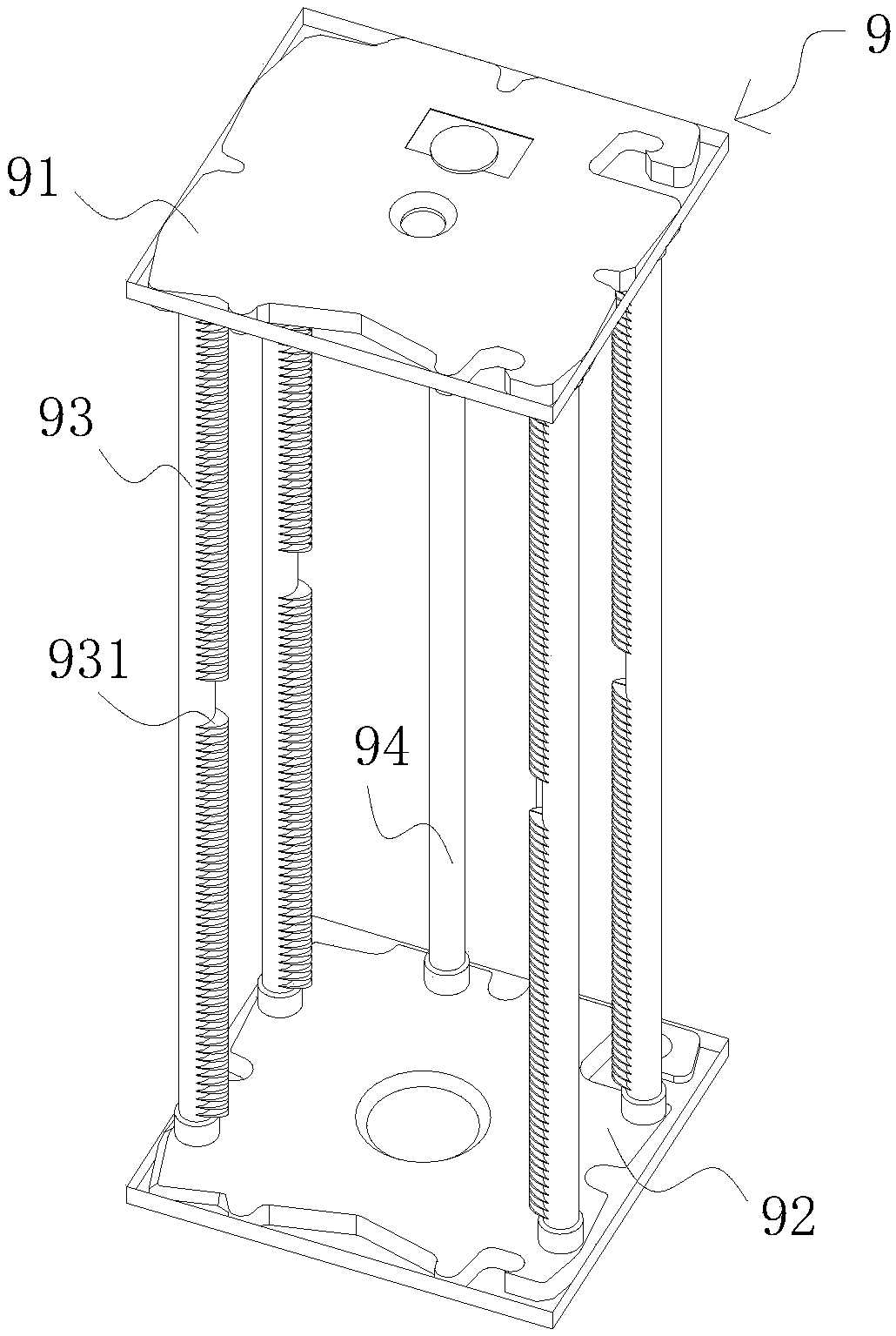

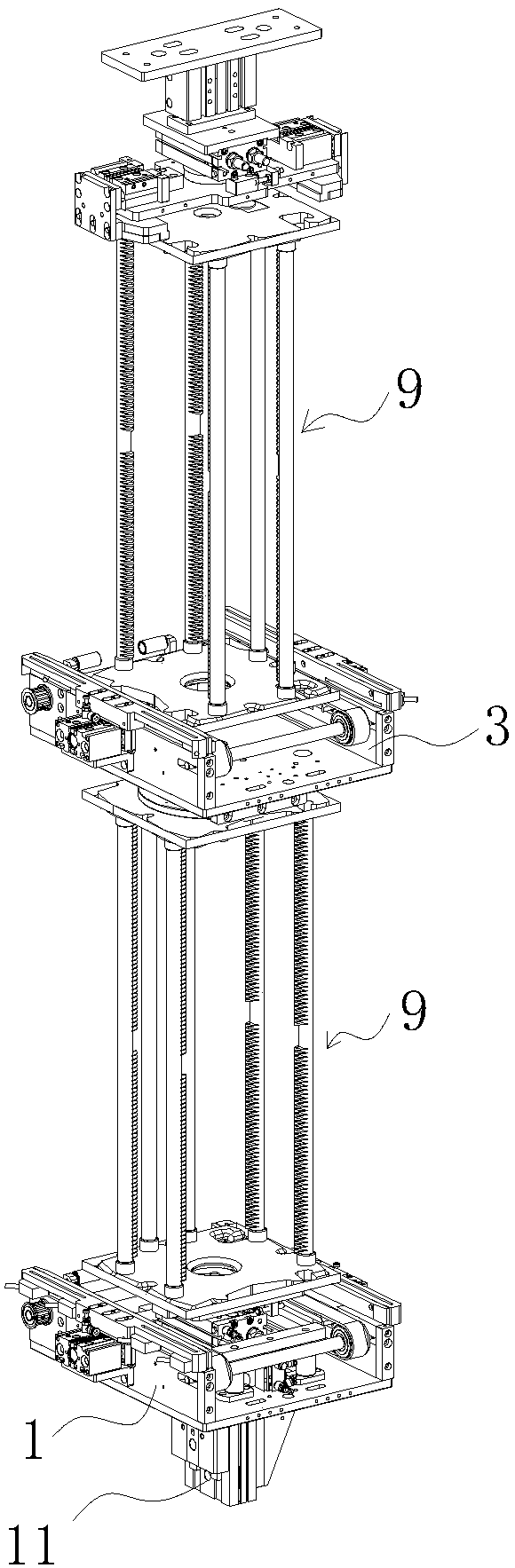

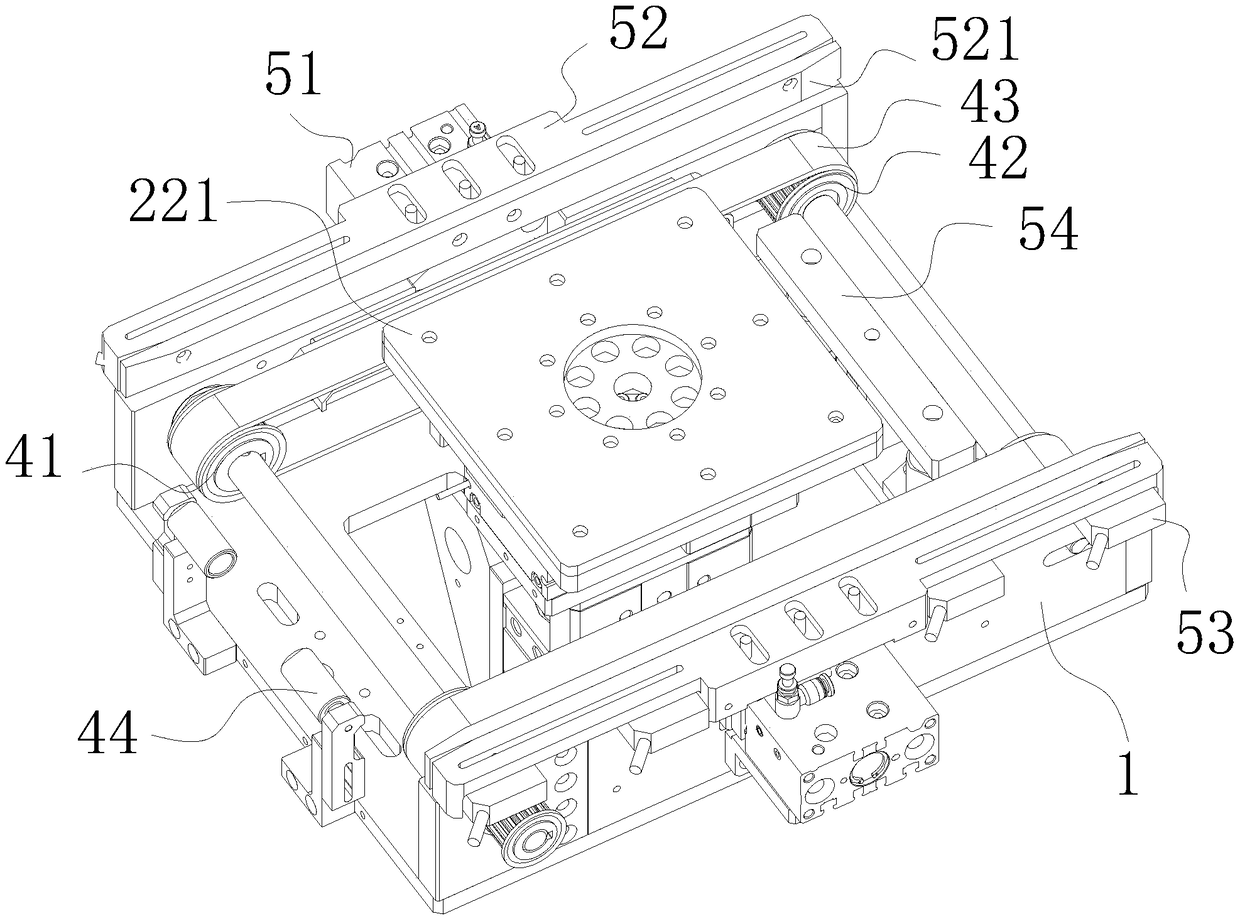

[0030] A fast rotating device for flower baskets, refer to figure 2 , including the forward rotation device set on the lower layer and the reverse rotation device set on the upper layer. In this embodiment, the forward rotation device and the reverse rotation device only rotate in opposite directions, and the forward and reverse directions do not limit the specific rotation direction. . The forward rotation device and the reverse rotation device respectively include a first base 1 and a second base 3 for supporting the flower basket 9. In this embodiment, the first base 1 and the second base 3 can be fixed with other objects, thereby forming A production line capable of continuously transporting flower baskets 9.

[0031] refer to image 3 and Figure 4 The forward rotation device also includes a first lifting member 11 arranged below the first base 1, the first lifting member 11 is fixed at the center of the first base 1, and the extension rod of the first lifting member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com