Mixing bowl having suction cup

A bottom surface and structure technology, applied in the field of mixing bowls, can solve problems such as suction cups being obstructed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

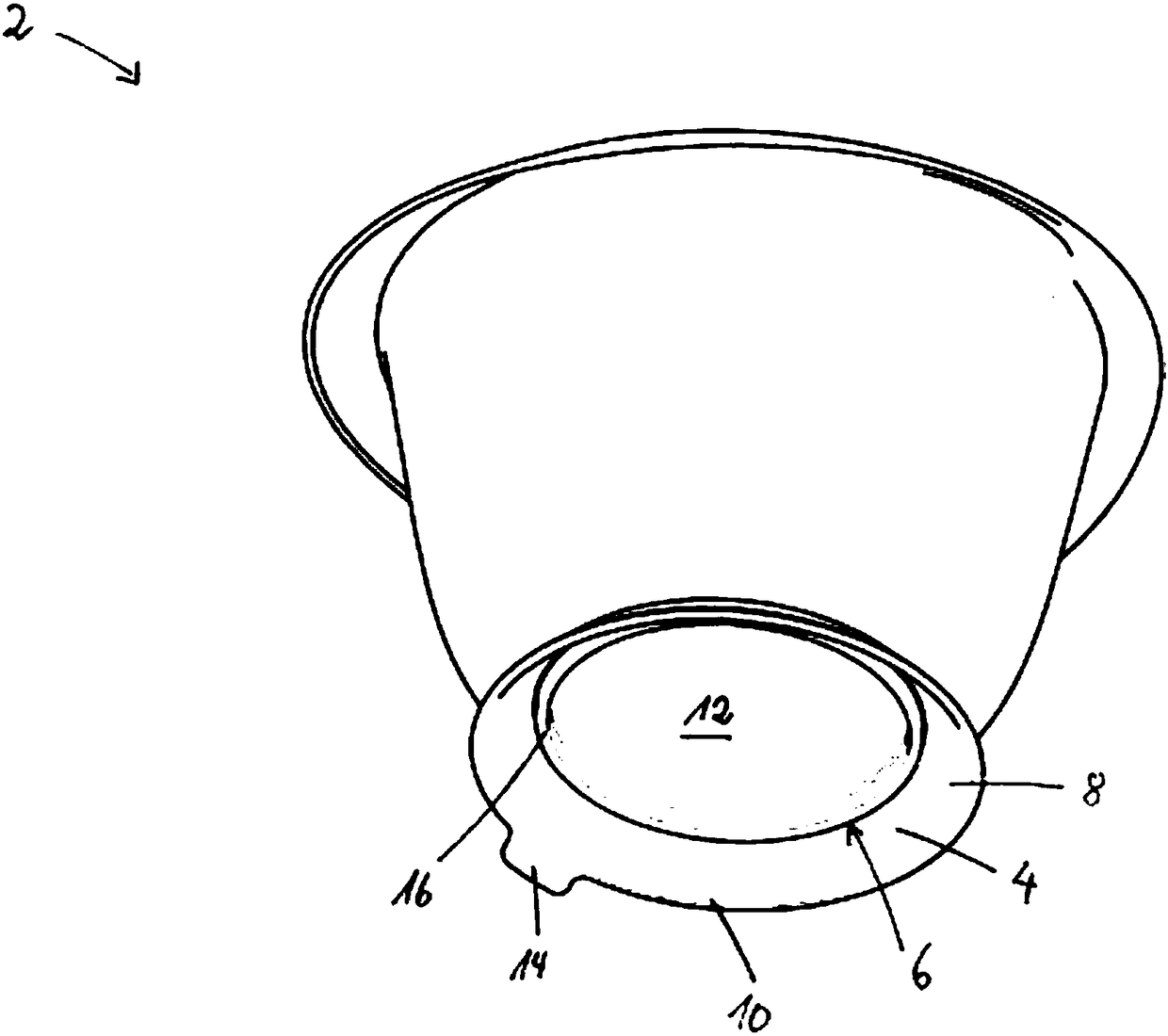

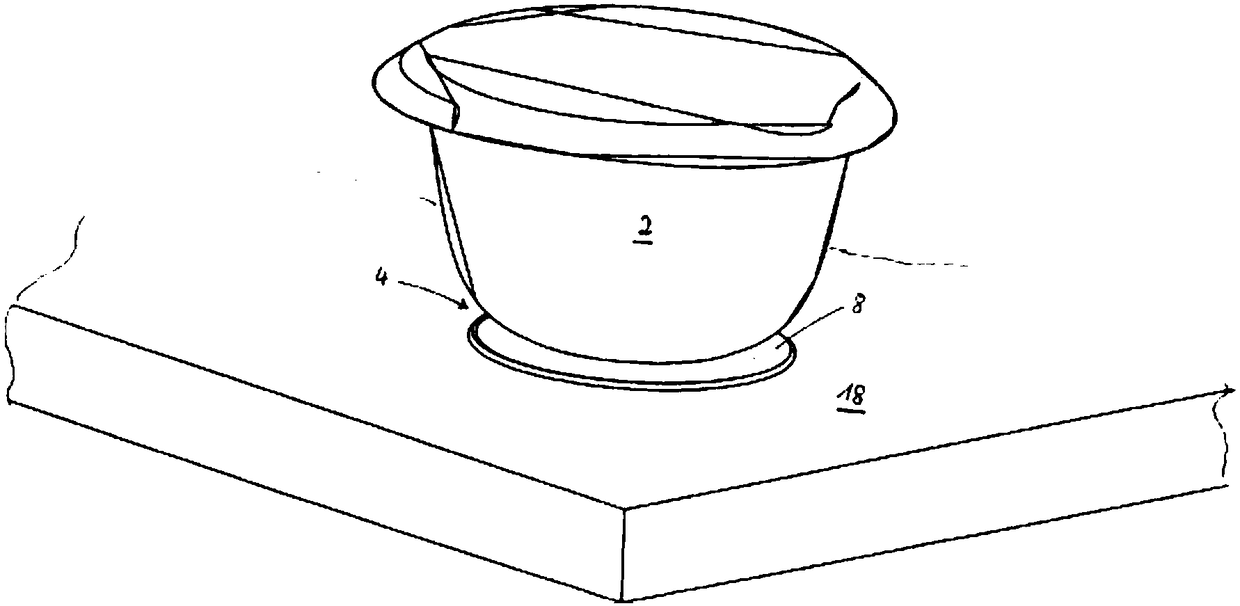

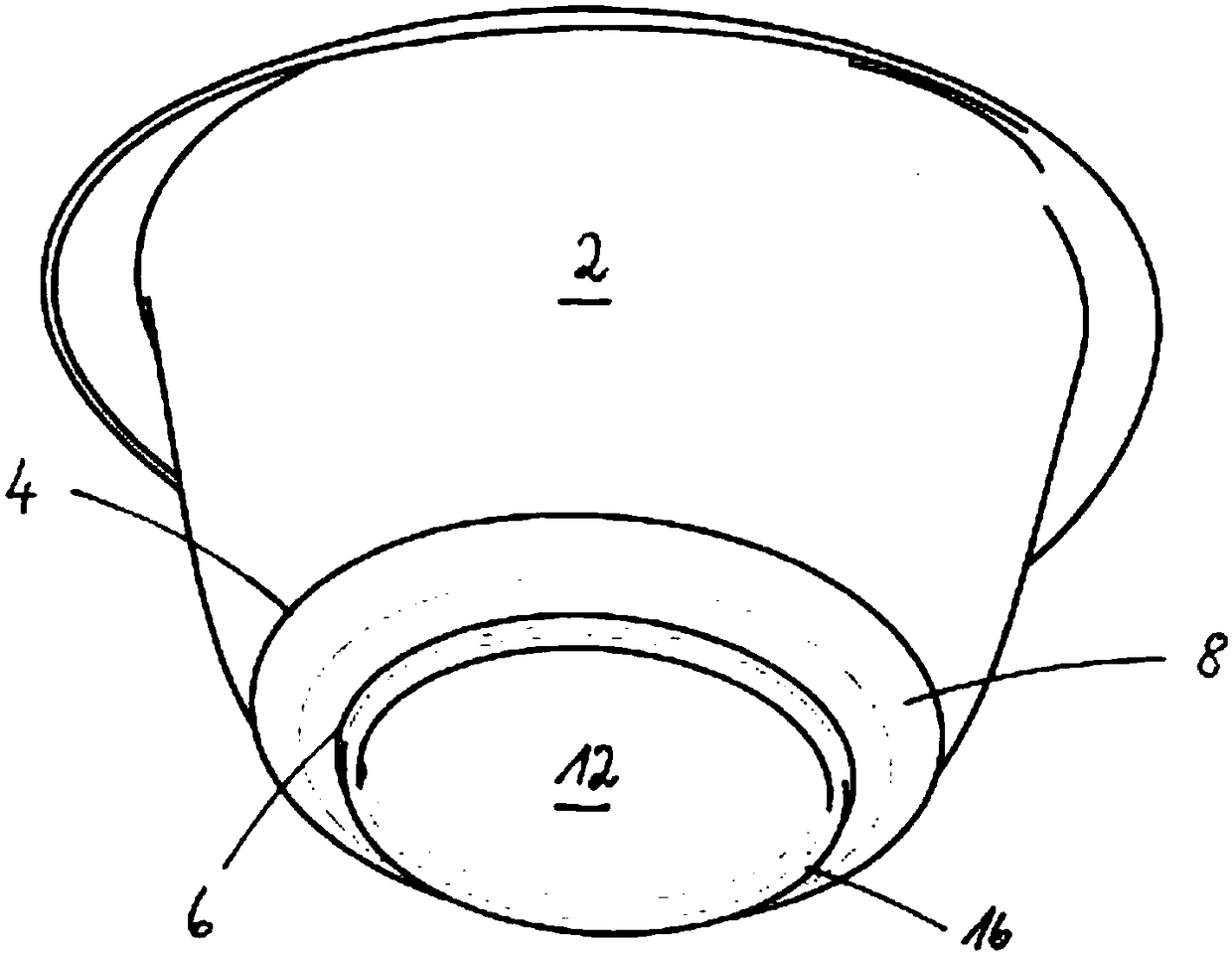

[0025] exist figure 1 The view from below shows mixing bowl 2 in . From this view, the sealing ring 4 can be clearly seen, which is connected with the mixing bowl 2 in a gas-tight manner with its inner edge region. The sealing ring 4 has a movable lip 8 which extends radially outwards from the edge region 6 . exist figure 1 In the relaxed position shown in , the lip, which is designed as a flat seal in this example, is oriented obliquely downwards.

[0026] On its underside, the movable lip has an annular bearing surface 10 , which begins at the outer edge of the movable lip 8 and which can increase inward according to the load acting on the movable lip 8 . In this embodiment, the bearing surface 10 is an annular surface.

[0027] In this exemplary embodiment, the edge region 6 of the sealing ring 4 is arranged on the outer edge of the bottom surface 12 of the mixing bowl 2 . Thus, the bottom surface 12 has a larger radius and covers a relatively larger area. Since the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com