Substrate for flexible devices

A flexible device and substrate technology, applied in lighting devices, transportation and packaging, climate sustainability, etc., can solve the problems of vulnerability to impact, lack of adhesion to stainless steel substrates, easy bending, etc., to reduce air bubbles, excellent durability Improvement of bendability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

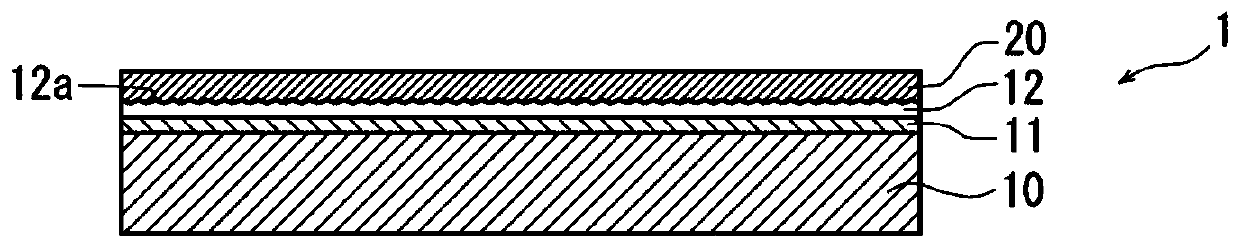

preparation example Construction

[0078]

[0079] In the preparation of the glass paste, the glass frit of the above glass composition is pulverized to form a glass composition powder, which is then mixed with a medium and dispersed.

[0080]The glass composition powder is obtained by mixing the glass composition, heating at a temperature of 800 to 1200° C. to form molten glass, quenching to obtain frit, and pulverizing the frit. Pulverization may be performed by any conventionally known method, and examples include JET pulverization, flash mill pulverization, and ball mill pulverization.

[0081] In order to smooth the glass surface, the average particle diameter of the glass composition powder is 20 μm or less, preferably in the range of 1 to 10 μm, more preferably in the range of 1 to 5 μm. In order to obtain a fine powder, JET comminution is preferred.

[0082] Then, the glass composition powder thus obtained is mixed with a medium and dispersed. Examples of the mixing-dispersing method include dispers...

Embodiment

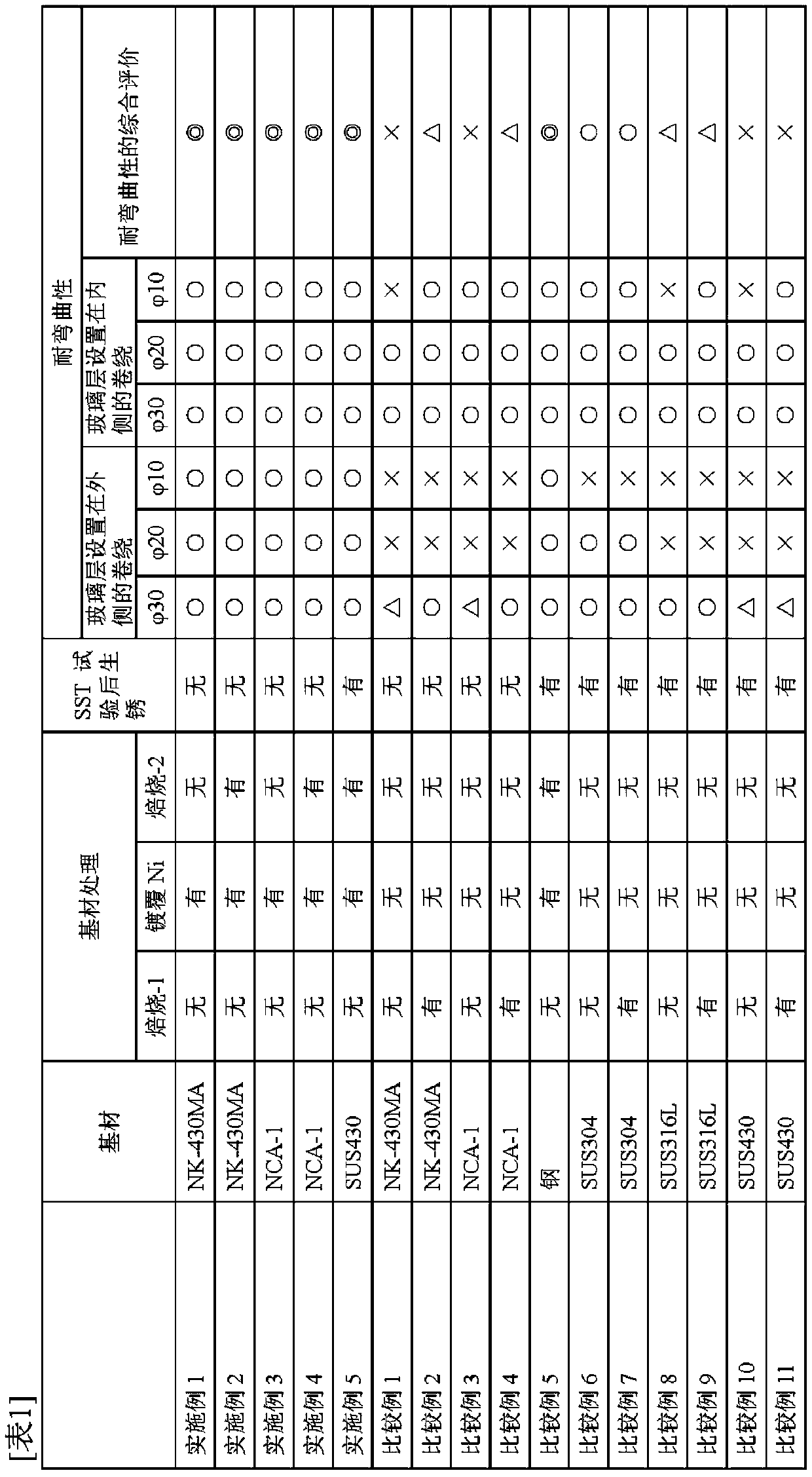

[0094] 1. Stainless steel substrate

[0095] Five types of stainless steel substrates with a thickness of 0.05 mm were used.

[0096] NK-430MA: Ferritic stainless steel foil (manufactured by Nippon Kinzoku Co., Ltd.)

[0097] NCA-1: Ferritic stainless steel foil (manufactured by Nippon Steel Nisshin Co., Ltd.)

[0098] SUS430: Ferritic stainless steel foil

[0099] SUS304: Austenitic stainless steel foil

[0100] SUS316L: Austenitic stainless steel foil

[0101] For the steel substrate used in the comparative example, a steel sheet obtained by annealing and degreasing a cold-rolled sheet (thickness: 0.05 mm) of ordinary steel was prepared.

[0102] Next, the above base material (dimensions: 20 cm in length, 50 cm in width) was subjected to alkaline electrolytic degreasing and pickling by immersion in sulfuric acid.

[0103] 2. Substrate treatment

[0104] The surface of the substrate is subjected to any one of the treatments of firing-1, nickel plating and firing-2 as sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com